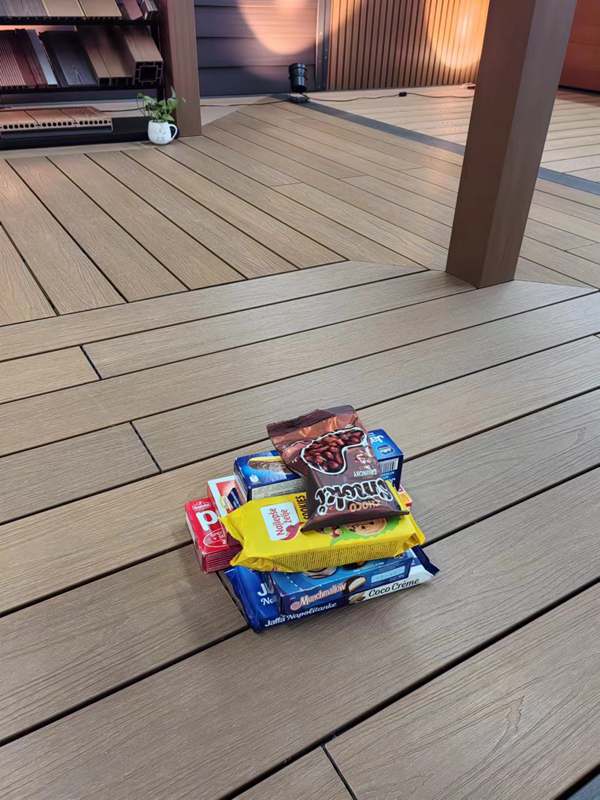

wrapped composite decking

Let’s take a look at some of the highlights of wrapped composite decking. ..

This type of floor not only has excellent environmental performance and avoids the formaldehyde pollution that may be caused by the use of glue in traditional wooden floors, but the functional materials covered on its surface can significantly improve the wear resistance, anti-aging and flame retardant properties of the floo

In outdoor courtyard decoration, the choice of flooring materials is a crucial part.

With the advancement of science and technology and the improvement of environmental awareness, wrapped composite decking is gradually becoming a new favorite in the market because of its unique performance and aesthetics. ..

However, the technical difficulties involved in the production of this material cannot be ignored.

Let’s take a look at some of the highlights of wrapped composite decking. ..

This type of floor not only has excellent environmental performance and avoids the formaldehyde pollution that may be caused by the use of glue in traditional wooden floors, but the functional materials covered on its surface can significantly improve the wear resistance, anti-aging and flame retardant properties of the floor.

What’s more worth mentioning is that after special processing, the surface texture of plastic wood flooring is more natural and lifelike, which greatly improves its aesthetics and practical value. ..

However, in the process of producing wrapped composite decking, companies often face many technical challenges. .

For example, how to improve production efficiency while ensuring product quality? How to deal with the fluidity of raw materials at high temperatures to keep the shape and size of the floor stable? Or, how to ensure the uniformity and density of the coating to avoid problems of delamination or wear during later use?

In response to these problems, the industry has proposed some effective solutions.

For example, by improving production equipment and technology and optimizing process flows, production speed can be increased without sacrificing quality; using high-quality raw materials and additives can improve the performance of materials during processing; and for surface coating technology, The quality and appearance of the coating layer can be ensured by finely controlling factors such as co-extrusion temperature, speed and pressure.

Nonetheless, to truly overcome these technical difficulties requires continued R&D and innovation within and outside the industry.

Only by continuously exploring and applying new materials and new technologies can the production of wrapped composite decking reach a new level and meet the market’s demand for high-performance and high-standard building materials. …

Wrapped composite decking is becoming the choice of more and more families due to its excellent environmental performance and aesthetics. ..

Although technical difficulties in the production process still exist, with the continuous advancement of technology and the gradual improvement of industry solutions, it is believed that the manufacturing and application of this material will become more mature and widespread in the future.