Wide Development of WPC Wood Plastic Composite Materials for Outdoor Use

Wide Development of WPC Wood Plastic Composite Materials for Outdoor Use With the development of the construction industry, WPC DECKING customization will become a trend. Based on the actual needs of the scene and meeting the actual functional requirements of the floor, the surface design of the floor should follow the principles of functionality and…

Wide Development of WPC Wood Plastic Composite Materials for Outdoor Use

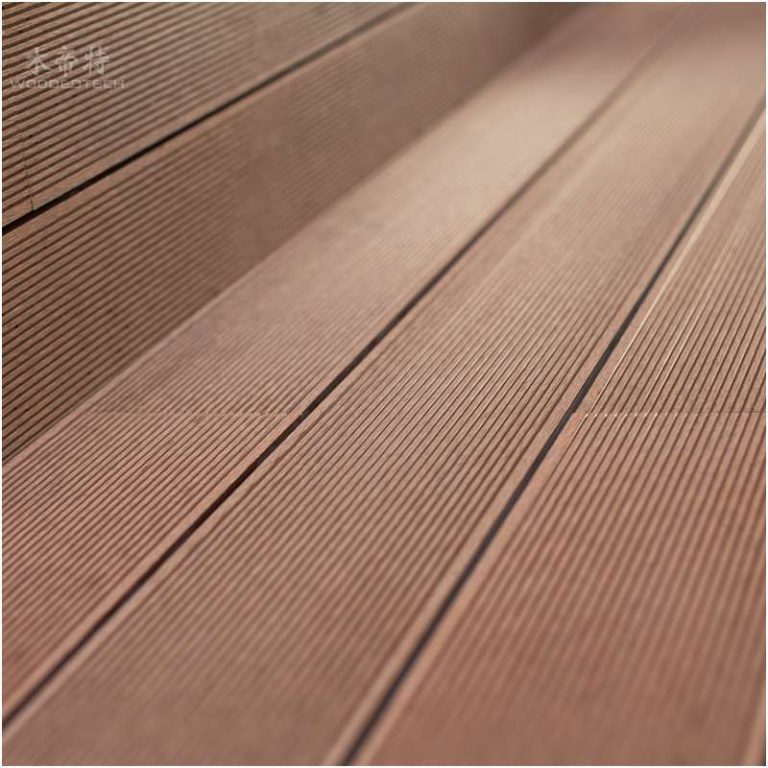

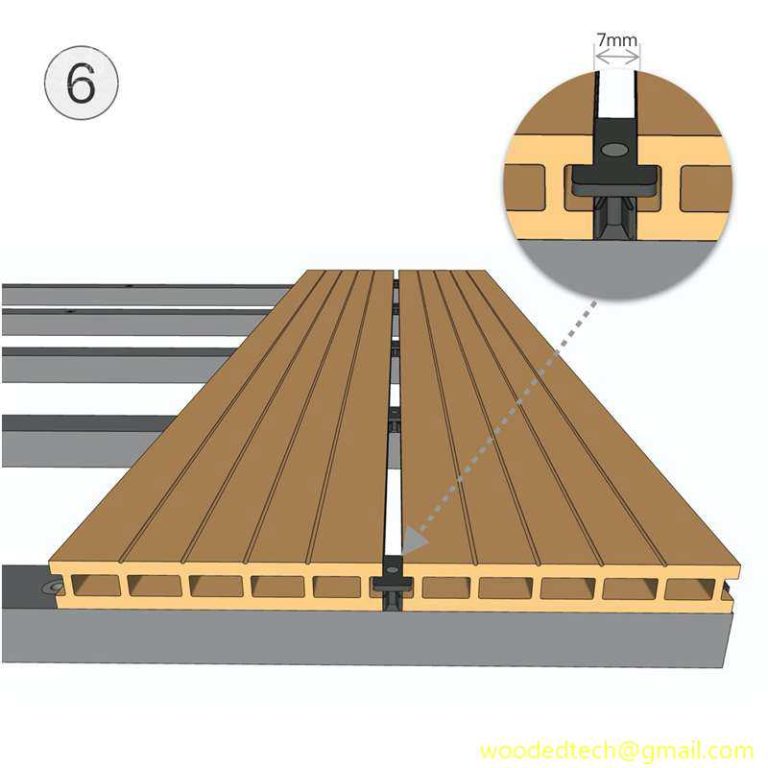

With the development of the construction industry, WPC DECKING customization will become a trend. Based on the actual needs of the scene and meeting the actual functional requirements of the floor, the surface design of the floor should follow the principles of functionality and aesthetics, making the surface design of WPC DECKING more beautiful and practical.

With the comprehensive utilization of resources and the enhancement of environmental awareness, WPC wood plastic composite materials are receiving increasing attention from countries around the world and have entered a stage of rapid development. Used in fields such as landscape architecture, outdoor building materials, furniture, logistics facilities, municipal facilities, docks and ports, and indoor and outdoor decoration. The use of plastic wood materials in the near water area can fully leverage the advantages of good water resistance of plastic wood and significantly improve its cost-effectiveness. Therefore, the application development in this area is very fast. Plastic wood engineering on the lake surface,such as plastic wood paving in wetland parks.

The traditional floor materials around swimming pools are cement, marble, and ceramic tiles. The surface temperature of these floors is greatly affected by the environment, and foot contact can produce a strong sense of stimulation; The water resistance of wooden flooring is poor, and there is a risk of wood thorn damage. The characteristics of the performance of plastic wood composite materials can precisely avoid the above-mentioned defects, so their application in this area can fully leverage their advantages.

Port and dock planking. Due to the significantly lower water absorption rate of plastic wood composite materials compared to natural wood, the small size change rate after water absorption, and the ability to resist seawater corrosion and have a long service life, it is the most ideal substitute for wood materials in ports and docks. It is also a large yacht club in Kunshan, Jiangsu and a yacht dock in West Lake, Hangzhou. The nearby villa has a plastic and wooden terrace. With the improvement of the performance, design, and construction level of WPC wood plastic composite materials in China, the application of hydrophilic terraces has also begun to develop.

Due to the advantages of water resistance, corrosion resistance, no wood thorns, no need for paint, and long service life compared to wood, WPC DECKING is still the most widely used product in plastic wood products. It is widely used in outdoor flooring, such as terrace flooring, balcony flooring, stack bridge flooring, flooring around indoor and outdoor swimming pools, and outdoor step boards. At present, there is also the use of plastic wood materials as base flooring, with wear-resistant or decorative layers on top, which are applied in indoor humid areas, such as bathrooms, kitchens, etc. However, due to its lower creep resistance, rigidity, and bending strength compared to solid wood, it is often necessary to adjust the support span of the keel according to the performance of the material during use to make up for it.