New research and development trends of plastic wood composite materials: sound barrier wood plastic composite materials

New research and development trends of plastic wood composite materials: sound barrier wood plastic composite materials Sound barriers are mainly used for sound insulation and noise reduction of highways, highways, elevated composite roads, and other noise sources. At present, there are many types of sound-absorbing and insulating boards used for sound barriers, which can be…

New research and development trends of plastic wood composite materials: sound barrier wood plastic composite materials

Sound barriers are mainly used for sound insulation and noise reduction of highways, highways, elevated composite roads, and other noise sources. At present, there are many types of sound-absorbing and insulating boards used for sound barriers, which can be mainly divided into metal based sound-absorbing boards and non-metallic sound-absorbing boards based on materials. Railway sound barriers are used in harsh environmental conditions. Although metal sound barriers can meet the requirements of sound absorption, sound insulation, and mechanics, their durability is relatively poor, with a general service life of about ten years. Using non-metallic materials can save costs on one hand and greatly improve the service life of sound barriers on the other hand.

Non metallic materials have the following characteristics:

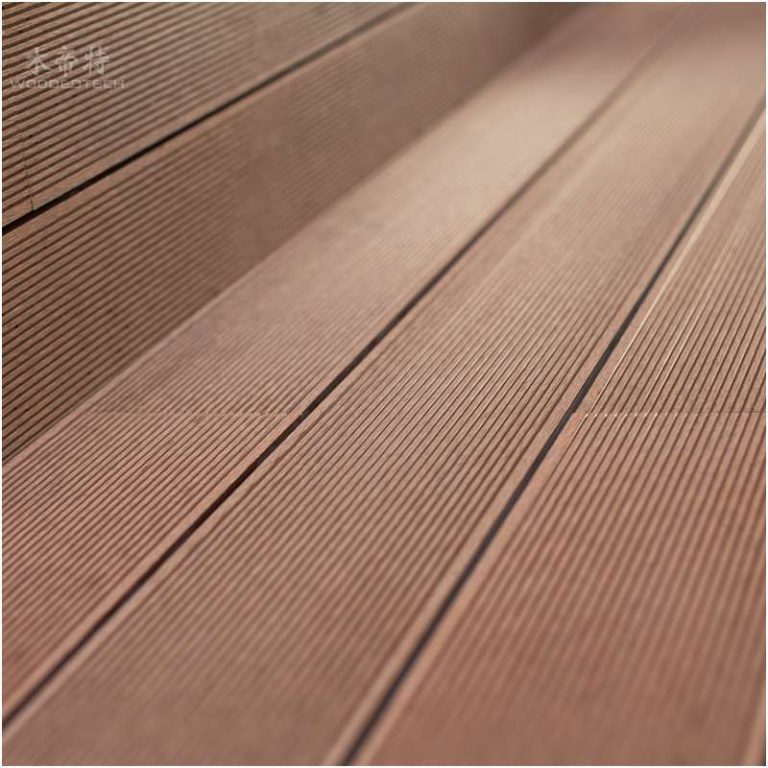

(1) The surface hardness is high, and its bending strength and bending modulus reach above 50MPa and 4.5GPa respectively, with strong load bearing capacity;

(2) Good dimensional stability, no cracking or warping;

(3) Good durability: water resistance, fire resistance, corrosion resistance, UV resistance, especially suitable for high temperature and high humidity areas, with a service life of up to 25-50 years;

(4) Reusable and recyclable, environmentally friendly, etc.

However, non-metallic sound-absorbing panels also suffer from issues such as poor sound insulation and heavy weight, making them difficult to construct and maintain, and limiting their application areas.

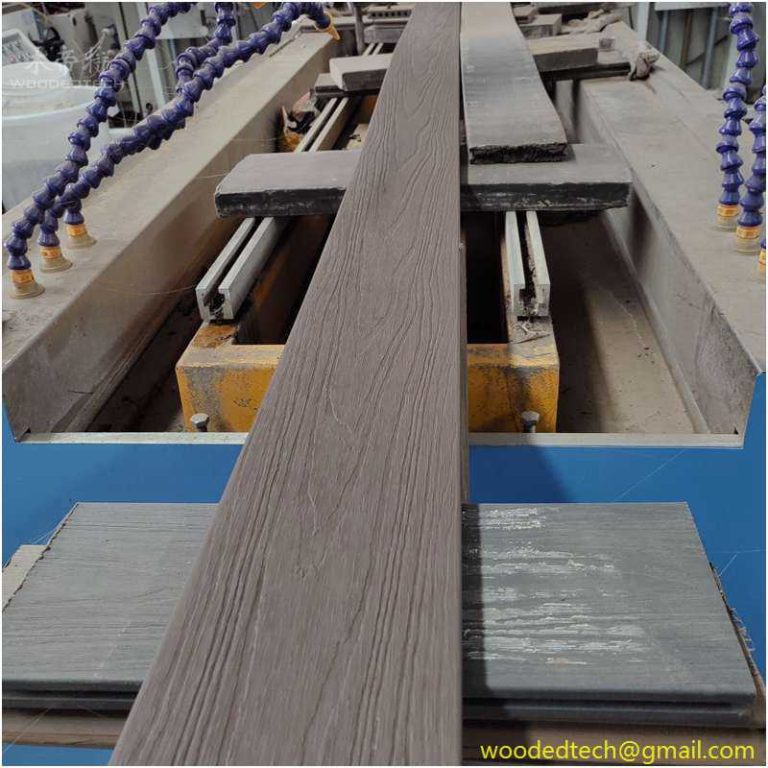

A patent provides a fiber reinforced wood plastic composite foam sound-absorbing board, comprising two layers of skin layers and a foam layer located between the two layers of skin layers; The skin layer is made of the following materials by weight parts: wood powder 40-50, polyethylene resin particles 20-30, skin layer coupling agent 2-3, anti-aging agent 2-3, flame retardant 2-3, lubricant 1-2 and light calcium carbonate 2-3; The foaming layer is made of the following weight fractions of raw materials: short cut waste wood plastic composite fiber 7-8, foaming layer coupling agent 1-2, foaming agent 4-5, foaming regulator 1-2, and polyurethane 7-9.

Among them, the coupling agent for the epidermal layer and the coupling agent for the foaming layer both refer to the coupling agent, specifically referring to the coupling agent used for making the epidermal layer and the coupling agent used for making the foaming layer, respectively. Short cut waste plastic wood composite material fibers refer to the shorter length products obtained from the secondary crushing of waste plastic wood composite boards.

Fiber reinforced wood plastic composite foam sound-absorbing board, including two layers of skin layer and a foam layer between the skin layer. The foam layer is filled with foaming agent to form some honeycomb shaped small holes. This makes the plastic wood composite foam sound-absorbing board not only lightweight and hard, but also has a good sound absorption and sound insulation effect with a microporous structure.

Among them, the raw materials for the foam layer also include short cut waste plastic wood composite fibers processed through two rounds of crushing, which can increase overall strength and serve as a “reinforcing body”. It has advantages such as light weight, high hardness, and excellent sound insulation effect.