Soluções rentáveis de substituição de madeira plástica para renovações de casas sustentáveis e duradouras

Soluções rentáveis de substituição de madeira plástica para renovações domésticas sustentáveis e duradouras Nos últimos anos, as indústrias da construção e da renovação têm vindo a reconhecer cada vez mais a importância da sustentabilidade e da durabilidade na seleção de materiais. A madeira tradicional, embora esteticamente agradável, tem muitas vezes custos ambientais significativos, incluindo a desflorestação, a destruição de habitats e requisitos de manutenção elevados. Como resultado, a procura...

Soluções rentáveis de substituição de madeira plástica para renovações de casas sustentáveis e duradouras

In recent years, the construction and renovation industries have increasingly recognized the importance of sustainability and durability in material selection. Traditional wood, while aesthetically pleasing, often comes with significant environmental costs, including deforestation, habitat destruction, and high maintenance requirements. As a result, the search for alternative materials has led to the development of plastic wood replacements—innovative solutions that offer a sustainable and durable option for home renovations.

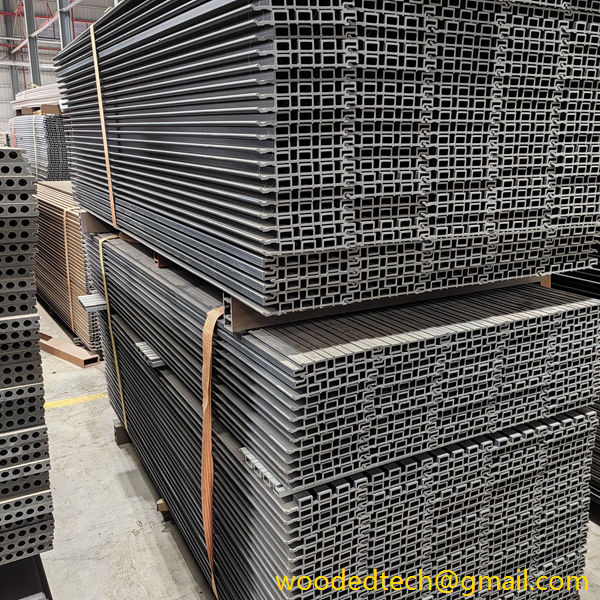

Plastic wood, also known as composite lumber or synthetic wood, is typically made from a combination of recycled plastics and wood fibers. This combination not only addresses the environmental issues associated with traditional wood but also enhances the longevity and performance of the material. The production of plastic wood involves processing post-consumer waste, such as discarded plastic bottles and wood scraps, leading to a reduction in landfill waste and the conservation of natural resources.

One of the most significant advantages of plastic wood is its durability. Unlike traditional wood, which is susceptible to rot, insects, and weathering, plastic wood is resistant to these common issues. This resilience means that homeowners can expect a longer lifespan for their materials, which translates into lower replacement and maintenance costs over time. For instance, plastic wood does not require regular sealing, staining, or painting, which not only saves money but also reduces the frequency of harmful chemical applications that can be detrimental to the environment.

Cost-effectiveness is another critical factor that makes plastic wood an attractive option for home renovations. While the initial investment might be higher compared to conventional wood, the long-term savings associated with reduced maintenance and replacement costs can make plastic wood a more economical choice in the long run. Moreover, as production technologies continue to advance and the demand for sustainable materials increases, the pricing of plastic wood is expected to become more competitive, making it accessible to a broader range of homeowners.

A variety of plastic wood products are available on the market, providing numerous options for different applications in home renovations. Decking is one of the most popular uses for plastic wood, as it combines aesthetics with functionality. Composite decking is available in various colors and textures, allowing homeowners to customize their outdoor spaces without compromising on sustainability. Additionally, many manufacturers offer warranties on their products, further assuring customers of their durability and value.

Another application of plastic wood is in siding and fencing. Traditional wood siding can warp and deteriorate over time, requiring constant upkeep. In contrast, plastic wood siding is engineered to withstand the elements, maintaining its appearance for years without the need for extensive maintenance. Similarly, plastic wood fencing provides an attractive and durable alternative that can withstand harsh weather conditions without rotting or fading.

In addition to decking, siding, and fencing, plastic wood is also versatile enough to be used in various indoor applications. For example, it can be used for cabinetry, furniture, and flooring. The aesthetic appeal of plastic wood products allows homeowners to achieve the look of natural wood without the associated environmental impact. Furthermore, many plastic wood products are designed to be easily fabricated, making them a suitable choice for custom projects.

The environmental benefits of plastic wood extend beyond its composition and durability. By choosing plastic wood products, homeowners contribute to a circular economy that emphasizes recycling and resource conservation. The use of recycled materials in the production of plastic wood minimizes the demand for virgin resources and helps reduce the carbon footprint associated with the manufacturing process. This shift towards more sustainable building materials aligns with the growing movement towards eco-friendly home renovations.

Furthermore, the adoption of plastic wood in home renovation projects can foster greater awareness of sustainability in the construction industry. By showcasing these innovative materials, homeowners can encourage others in their community to consider eco-friendly alternatives in their own projects. This ripple effect can lead to increased demand for sustainable products, driving even more innovation and investment in the development of cost-effective solutions.

In conclusion, plastic wood replacement solutions represent a promising avenue for homeowners looking to undertake sustainable and durable renovations. With their inherent resistance to weathering, insects, and decay, along with their low maintenance requirements, these materials offer a compelling alternative to traditional wood. The cost-effectiveness of plastic wood, combined with its versatility in various applications, makes it an attractive choice for modern home renovation projects. As the industry continues to evolve and prioritize sustainability, plastic wood is poised to play a crucial role in shaping the future of construction and renovations, ultimately benefiting both homeowners and the environment.