Production process and functional modification of wood plastic composite materials

Production process and functional modification of wood plastic composite materialsSo far, WPC production mainly uses extrusion molding, hot pressing molding, and injection molding technologies. The influence of process on the physical and mechanical properties of extruded wood plastic composite materials was studied. The results showed that in the production of WPC with wood mass content…

Production process and functional modification of wood plastic composite materials

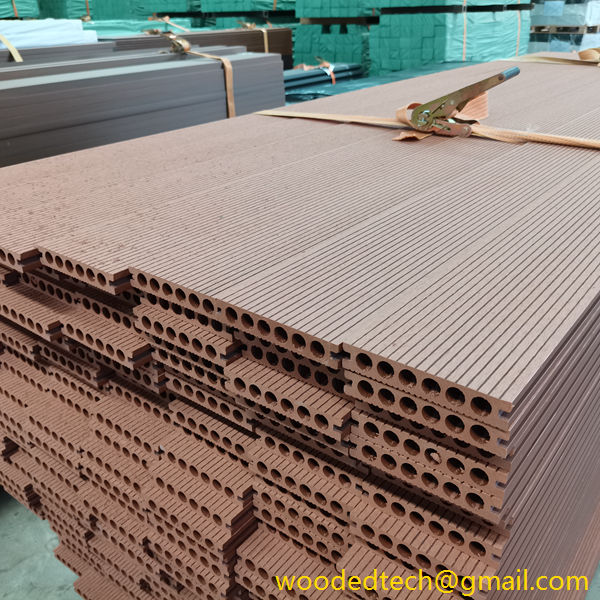

So far, WPC production mainly uses extrusion molding, hot pressing molding, and injection molding technologies. The influence of process on the physical and mechanical properties of extruded wood plastic composite materials was studied. The results showed that in the production of WPC with wood mass content of 50% and 70%, using the same WPC component can achieve better physical and mechanical properties.

By using various fiber powders mixed with PP through different processes, wood plastic composite materials were prepared. It was found that the mechanical properties and moisture absorption resistance of wood plastic composite materials formed by mixing and molding were better than those of laminated molded wood plastic composite materials. Japanese scholars have proposed a new method for producing wood powder from wood plastic composite materials and studied its mechanical properties.

In traditional wood powder production, a significant amount of time and effort is required to remove fine particles in order to achieve uniform wood powder size. The proposed new production process includes first using a disc mill for wet grinding, then drying, and finally using a disc mill for dry grinding, which can conveniently produce uniformly sized wood powder. The mechanical properties of PP based wood plastic composites were greatly improved by adding the prepared wood powder.

Functional modification

Flame retardant and smoke suppression modification

wood plastic composite materials contain a large amount of C, H, and O elements, which are very prone to dehydration, carbonization, or combustion, and combustion will produce a large amount of thick smoke or toxic gases. There are significant fire safety hazards in the use of components, greatly limiting their application in many fields. Flame retardant and smoke suppression modification has become one of the research focuses of wood plastic. A new flame retardant for wood plastic materials, Coleman ite, was studied.

The flame retardancy of wood plastic composites was evaluated using boron minerals (tin calcite, olivine, and gabbro). The results showed that boron minerals can be used as a substitute for commonly used flame retardant magnesium hydroxide and can enhance the flame retardancy of WPC. Research has found that adding organosilicon based, ammonium polyphosphate, and organophosphorus nitrogen flame retardants can improve the flame retardant effect of PE based wood plastic composite materials, with little impact on mechanical properties.

Aging and weather resistance modification

The aging and climate damage of WPC are mainly manifested by the effects of humidity, light, and temperature during use on its color, physical properties, and mechanical properties. Therefore, it is necessary to use effective additives or processing treatments to control the impact of natural environment on the properties of wood plastic composite materials. Research has found that after wood powder extraction or delignification treatment, the surface color of HDPE based WPC prepared has very little change after accelerated aging experiment, with high bending strength, static bending strength, and elastic modulus, and significantly improved aging and weather resistance.

Antibacterial modification

WPC has better microbial resistance than wood, but due to its plastic matrix not being able to completely seal the wood material and various organic additives added, it is also susceptible to mold rot and fungal invasion and damage. So the antibacterial modification of WPC is also an area that needs to be studied. The surface antibacterial properties of wood plastic materials grafted with polyacid antibacterial agents were studied, and the results showed that the WPC surface of the grafted heteropolyacid quaternary ammonium salt composite material had a good antibacterial effect on the above-mentioned bacteria.

This study fills the gap in the application of heteropolyacids in the antibacterial field of wood plastic materials and opens up new avenues for the functionalization of heteropolyacids. We studied how to improve the antibacterial properties of wood plastic composites produced from wood and plastic waste. In order to enhance the antibacterial properties of WPC, single/binary inorganic/organic antimicrobial agents were impregnated onto the surface, and all antimicrobial agents showed excellent bactericidal effects.

With the rapid development of science and technology, utilizing abundant natural plant fibers to enhance plastics is an important research direction for the sustained growth of polymer based composites. Therefore, wood plastic composites, as a new type of composite material with friendly characteristics such as low-carbon, green, environmental protection, and sustainable development, have attracted great attention.