How to Cut WPC Cladding: A Guide to Cutting WPC Cladding Effectively

How to Cut WPC Cladding: A Guide to Cutting WPC Cladding Effectively Cutting WPC (Wood Plastic Composite) cladding effectively requires an understanding of the material, the right tools, and specific techniques that ensure a smooth finish and reduces the risk of damage. WPC cladding has gained popularity in recent years due to its durability, low…

How to Cut WPC Cladding: A Guide to Cutting WPC Cladding Effectively

Cutting WPC (Wood Plastic Composite) cladding effectively requires an understanding of the material, the right tools, and specific techniques that ensure a smooth finish and reduces the risk of damage. WPC cladding has gained popularity in recent years due to its durability, low maintenance requirements, and aesthetic appeal. This guide aims to provide a comprehensive overview of how to cut WPC cladding efficiently while ensuring the best results.

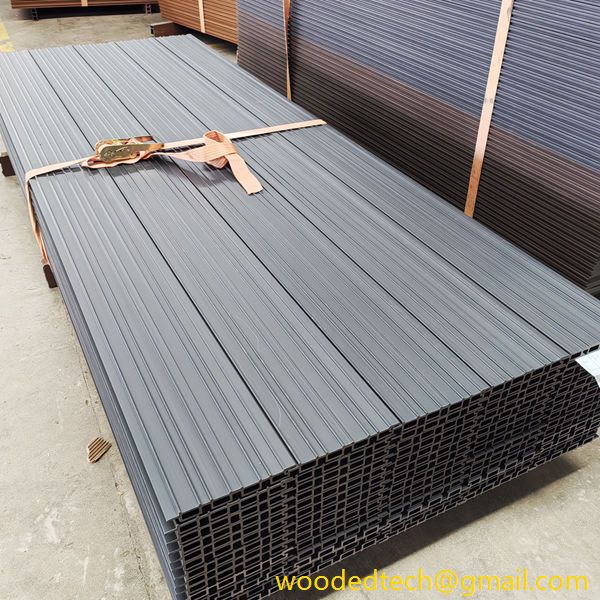

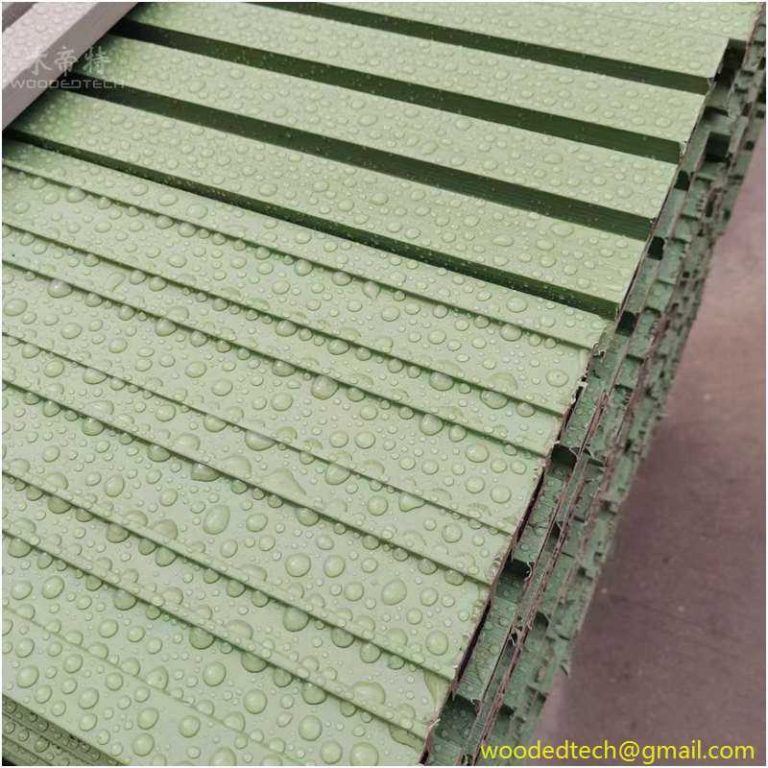

First, it is essential to understand what WPC cladding is. This composite material is made from a blend of wood fibers and plastic, which gives it the appearance of natural wood while offering superior durability and resistance to moisture, rot, and pests. WPC cladding is available in a variety of colors, textures, and finishes, making it a versatile choice for both residential and commercial applications. However, cutting this material requires specific techniques due to its unique properties.

Before beginning the cutting process, preparation is crucial. Start by gathering the necessary tools. You will need a circular saw or a miter saw, which are the most common tools for cutting WPC cladding. Ensure that the blades are sharp and designed for cutting composite materials. Using the right blade will make the cutting process smoother and reduce the likelihood of chipping or splintering. A fine-toothed blade is preferable, as it provides a cleaner cut.

In addition to the saw, you will also need safety equipment such as goggles and a dust mask. WPC cutting can produce fine dust particles that can be harmful if inhaled, so it is important to protect yourself. Also, ensure that your workspace is clean and free from obstructions. A clear area allows for better focus and reduces the risk of accidents while cutting.

Once you have prepared your tools and workspace, it’s time to measure and mark the WPC cladding. Accurate measurements are vital to ensure that the pieces fit together correctly. Use a measuring tape to determine the length needed for each section of cladding. After taking measurements, mark the cutting line clearly with a pencil or chalk. A straight edge can help you draw a precise line, which will guide your saw and lead to a cleaner cut.

When you are ready to cut, secure the WPC cladding firmly to a stable surface. Clamping it down will prevent any movement during cutting, which can lead to uneven edges or accidents. If you are using a circular saw, make sure to adjust the cutting depth to match the thickness of the cladding. This adjustment will help prevent the blade from binding and ensure a smooth cut.

As you begin cutting, maintain a steady hand and follow the marked line closely. It is important to let the saw do the work; applying too much pressure can result in uneven cuts or damage to the material. If you notice any signs of splintering as you cut, consider reducing the speed of the saw or using a finer blade. Slow and steady is the key to achieving a clean and professional-looking edge.

After you have completed the cuts, it is essential to finish the edges of the WPC cladding. Depending on your project, you may want to sand down any rough edges. Use a fine-grit sandpaper to smooth the edges carefully, which will not only enhance the appearance but also ensure a better fit during installation. Be cautious not to over-sand, as this could affect the integrity of the cladding.

If you are cutting WPC cladding for an outdoor project, consider sealing the edges with a suitable sealant. This step is particularly important for areas that might be exposed to moisture, as it will help enhance the material’s durability and resistance to the elements. Applying a sealant can also improve the overall finish and prolong the lifespan of your cladding.

In conclusion, cutting WPC cladding is a task that can be accomplished with the right tools, techniques, and preparation. By following these steps, you can achieve clean, precise cuts that enhance the appearance of your project while maintaining the integrity of the material. Remember to prioritize safety throughout the process, and take your time to ensure accuracy. Whether you’re working on a small renovation or a large-scale project, understanding how to cut WPC cladding effectively will provide you with the confidence to complete your tasks successfully. With its increasing popularity in the building industry, mastering the art of cutting WPC cladding will undoubtedly be a valuable skill for any DIY enthusiast or professional contractor.