wpc extrusion line

In this era of rapid technological development, the wpc extrusion line is like a magic converter that turns waste into treasures. .

And behind this is the wisdom and sweat of every engineer and technician.

Next time you walk into a space paved with WPC flooring, you might as well pay more attention to it. Perhaps it is such an efficient and environmentally friendly production line that brings us such a comfortable and beautiful environment. ..

Have you ever imagined that the floor you walk on might be made of waste plastic and wood chips? This is not a fantasy, but a product called wpc flooring is doing it. .

This product is not only environmentally friendly but also durable, so how does it do it?

Let’s start with a wpc extrusion line. ..

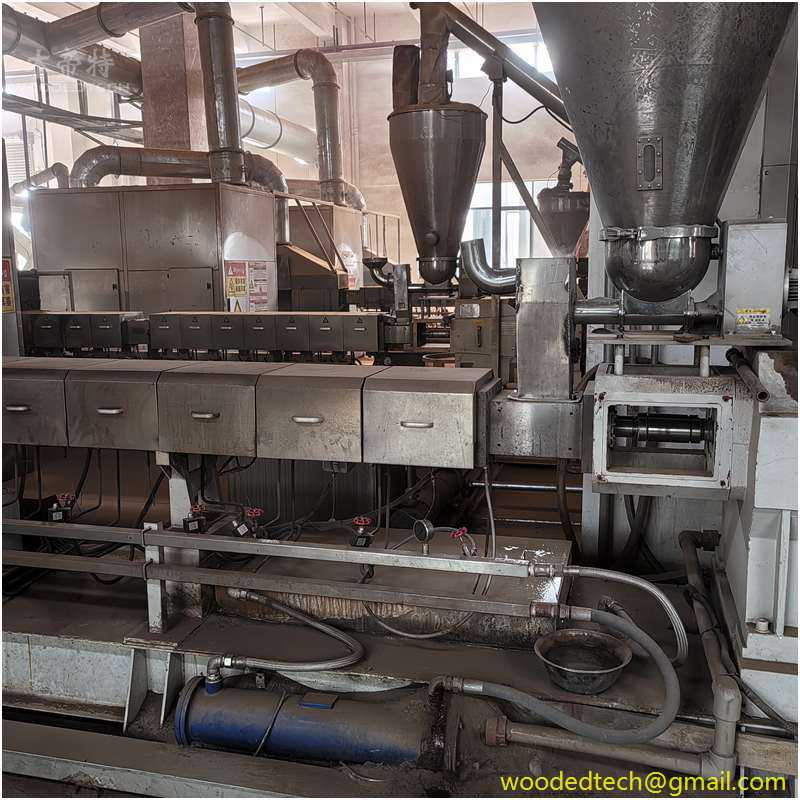

Such a production line usually contains several key parts: a conical twin-screw extruder, a vacuum shaping table, a tractor, a cutter and a turning rack. .

These components work together to transform recycled plastics and wood fibers into usable building materials.

The conical twin-screw extruder is the core of the entire production line. .

It is specially designed to allow the raw materials to be fully mixed and plasticized inside the machine.

In this process, the plastic and wood chips are heated, melted and evenly mixed to form a new material that is both strong and elastic.

Next is the vacuum shaping table.

Here, the newly formed material will be further shaped and cooled to ensure that its size and shape meet the requirements.

Afterwards, the traction machine takes over this task and guides the material forward to prepare for the next step of cutting.

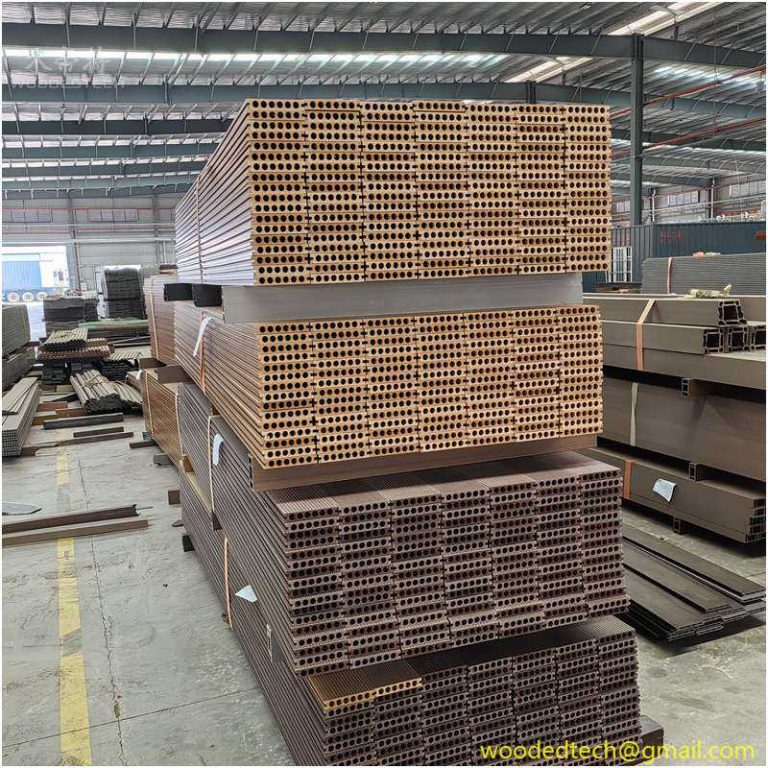

When it comes to the cutting stage, the precise cutting machine will divide the continuous material into standard-sized floor panels as needed. .

Finally, the turning rack is responsible for neatly stacking these panels for packaging and transportation.

Through this wpc extrusion line, we can not only produce beautiful and practical wpc floors, but also effectively reduce environmental pollution and realize the recycling of resources.

This is not only a victory of technology, but also a reflection of our friendly attitude towards the natural environment.

Of course, in addition to these “big guys” on the production line, some auxiliary equipment is also silently playing a role.

For example, chillers, printing machines, cooling towers, etc., although they are not directly involved in production, they can ensure the temperature control and efficiency improvement of the entire production process.

In this era of rapid technological development, the wpc extrusion line is like a magic converter that turns waste into treasures. .

And behind this is the wisdom and sweat of every engineer and technician.

Next time you walk into a space paved with WPC flooring, you might as well pay more attention to it. Perhaps it is such an efficient and environmentally friendly production line that brings us such a comfortable and beautiful environment. ..