wpc deck white

wpc deck white Wpc deck white production problem solved: co-extrusion technology leads the industry innovation Text: With the continuous improvement of environmental awareness, wpc deck, as a new type of environmentally friendly material, is increasingly favored by the market. However, in the production process of wpc deck, the technical difficulty of producing white with classic…

Wpc deck white production problem solved: co-extrusion technology leads the industry innovation

Text:

With the continuous improvement of environmental awareness, wpc deck, as a new type of environmentally friendly material, is increasingly favored by the market. However, in the production process of wpc deck, the technical difficulty of producing white with classic wpc deck has always been high, while the production of white with co-extrusion wpc deck is very simple and easy. This article will analyze the differences between the two production technologies in detail and explore how co-extrusion technology leads the industry innovation.

1. Technical difficulties in producing white with classic wpc deck

Limitations in raw material selection

When producing white with classic wpc deck, there are high requirements for the selection of raw materials. Since wpc deck white has high requirements for color purity, high-purity white masterbatch needs to be selected in the production process. However, there are many types of white masterbatches on the market, and the quality is uneven. Improper material selection can easily lead to color difference in the product.

Complex formula design

In the production process of wpc deck white, formula design is crucial. It needs to be reasonably matched according to factors such as raw material characteristics and product performance requirements. When designing the formula, factors such as the compatibility, stability and cost of various raw materials should be fully considered, which undoubtedly increases the difficulty of production.

Strict production process requirements

When the classic wpc deck is produced in white, the production process requirements are strict. During the production process, parameters such as temperature, pressure, and speed need to be strictly controlled to ensure product quality. Once the parameters are set improperly, it is easy to cause color difference, stratification, deformation and other problems in the product.

2. Technical advantages of co-extrusion wpc deck in producing white

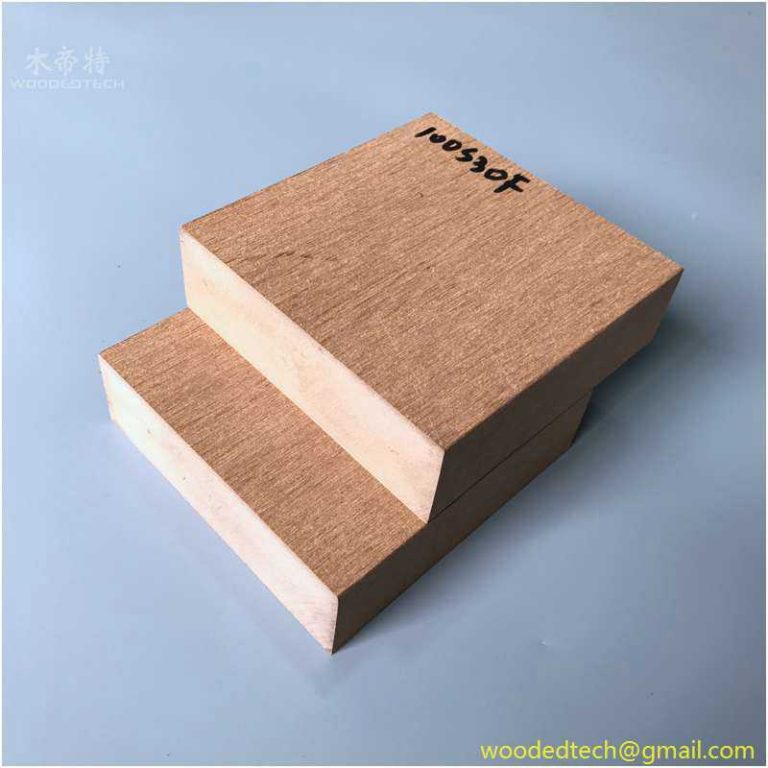

Versatility of raw materials

When co-extrusion wpc deck is produced in white, the requirements for raw materials are relatively low. Because the co-extrusion technology adopts a multi-layer composite structure, raw materials of different colors can be flexibly selected to match, so as to achieve a white effect. This makes co-extrusion wpc deck more versatile in raw material selection.

Simplified formula design

When co-extrusion wpc deck is produced in white, the formula design is relatively simplified. Because the co-extrusion technology divides the raw materials into multiple layers, the raw materials of each layer can be formulated separately, reducing the complexity of the overall formula. In addition, co-extrusion technology can also adjust the ratio of raw materials of each layer according to market demand to achieve personalized customization.

Simplified production process

When co-extrusion Wpc deck is produced in white, the production process is relatively simplified. Co-extrusion technology uses one extruder to complete the compounding of multiple layers of raw materials, which greatly reduces the difficulty of production. At the same time, co-extrusion technology can realize automated production, improve production efficiency, and reduce labor costs.

3. Co-extrusion technology leads industry innovation

Improve product quality

Co-extrusion Wpc deck adopts a multi-layer composite structure, which makes the product have better physical properties and weather resistance. In addition, co-extrusion technology can also achieve full mixing of raw materials, improve product stability, and reduce the probability of color difference, stratification and other problems in the product.

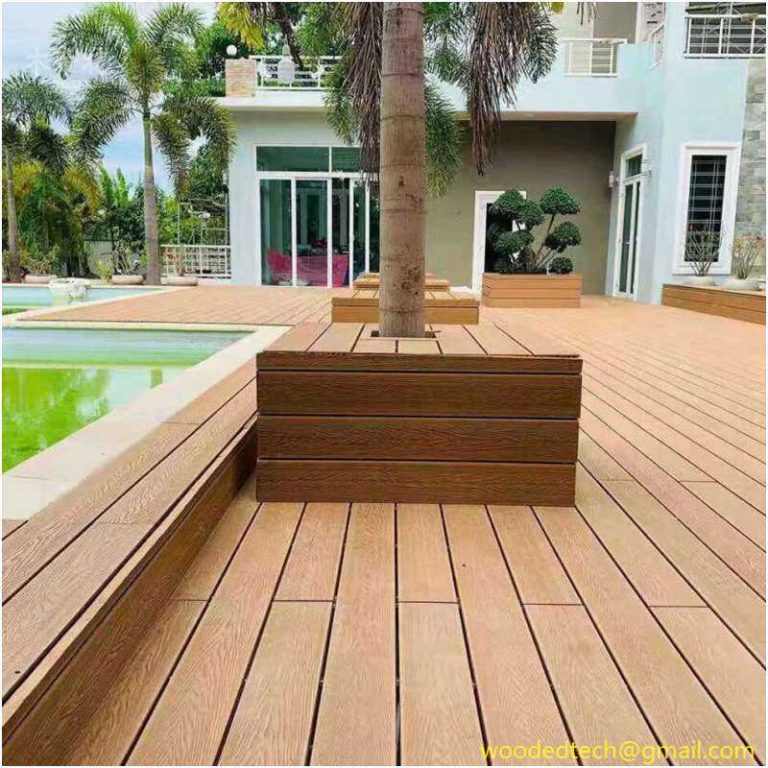

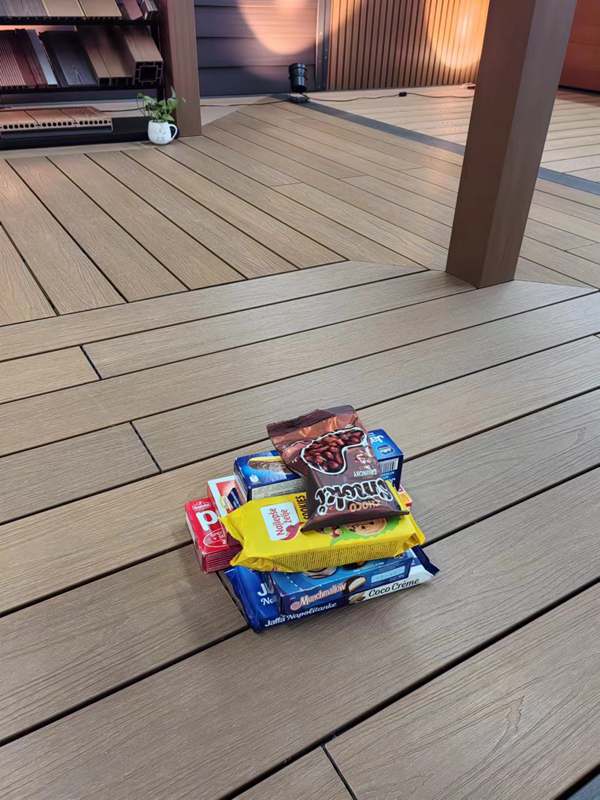

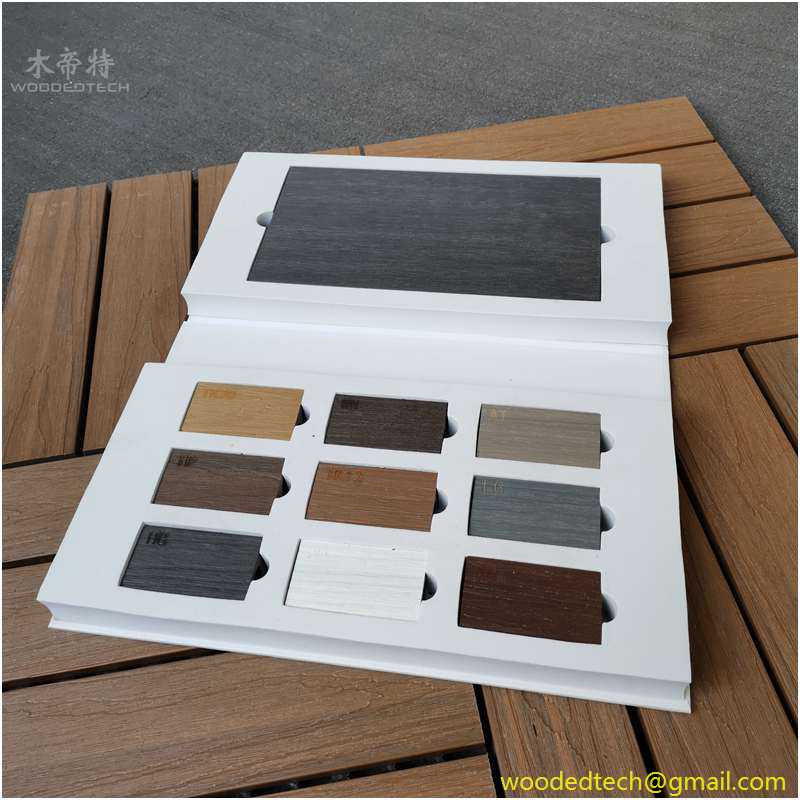

Enrich product variety

Co-extrusion technology makes the color, texture, and specifications of Wpc deck diversified to meet the needs of different scenarios and different customers. At the same time, co-extrusion technology can also realize personalized customization of products, providing consumers with more choices.

Reduce production costs

Co-extrusion technology simplifies the production process, reduces the difficulty of production, and thus reduces production costs. In addition, co-extrusion technology can also improve the utilization rate of raw materials, reduce waste, and further reduce production costs.

In short, co-extrusion technology has obvious advantages in the production of Wpc deck white. With the continuous maturity and popularization of co-extrusion technology, I believe that the market share of wpc deck white will continue to increase in the future, making greater contributions to my country’s environmental protection cause.