wpc core flooring

wpc core flooring Co-extruded wpc core flooring: Leading the new trend of green home Today, as environmental awareness in my country continues to improve, green home has become the first choice for more and more families. As a new environmentally friendly flooring product, co-extruded wpc core flooring has attracted widespread attention from consumers for its…

Co-extruded wpc core flooring: Leading the new trend of green home

Today, as environmental awareness in my country continues to improve, green home has become the first choice for more and more families. As a new environmentally friendly flooring product, co-extruded wpc core flooring has attracted widespread attention from consumers for its excellent performance and green and environmentally friendly characteristics. This article will introduce the composition, advantages and applications of co-extruded wpc core flooring in detail, so that you can fully understand this new green home product.

1. Composition of co-extruded wpc core flooring

Co-extruded wpc core flooring consists of two parts: core layer and co-extruded layer. The core layer adopts wood-plastic composite material, which is mainly made of wood powder, plastic and additives through high temperature and high pressure extrusion molding. The co-extruded layer adopts high-performance plastic, which is closely combined with the core layer through co-extrusion technology. This structure gives co-extruded wpc core flooring unique performance advantages.

2. Advantages of co-extruded wpc core flooring

1. Green and environmentally friendly: In the production process of co-extruded wpc core flooring, environmentally friendly materials are used, and no harmful substances are released. At the same time, the product can be recycled, reducing the impact on the environment.

2. Water-resistant and wear-resistant: The high-performance plastic of the co-extruded layer has excellent water resistance, making the co-extruded wpc core flooring not easy to deform and expand in a water environment. At the same time, the wear resistance has also been significantly improved, and the service life is longer.

3. Anti-slip and moisture-proof: The surface of the co-extruded wpc core flooring is treated with a special process and has good anti-slip properties. In a humid environment, the floor is not easily affected by moisture, ensuring the comfort of the home environment.

4. Good comfort: The co-extruded wpc core flooring feels comfortable and has good elasticity, which can effectively relieve fatigue when walking.

5. Easy installation: The co-extruded wpc core flooring adopts a splicing design, which is easy and quick to install. It does not require the use of adhesives such as glue, which reduces the release of harmful substances such as formaldehyde.

6. Good decorativeness: The surface of the co-extruded wpc core flooring can imitate a variety of textures such as wood grain and stone, and has rich colors to meet the matching needs of different home styles.

3. Application of co-extruded wpc core flooring

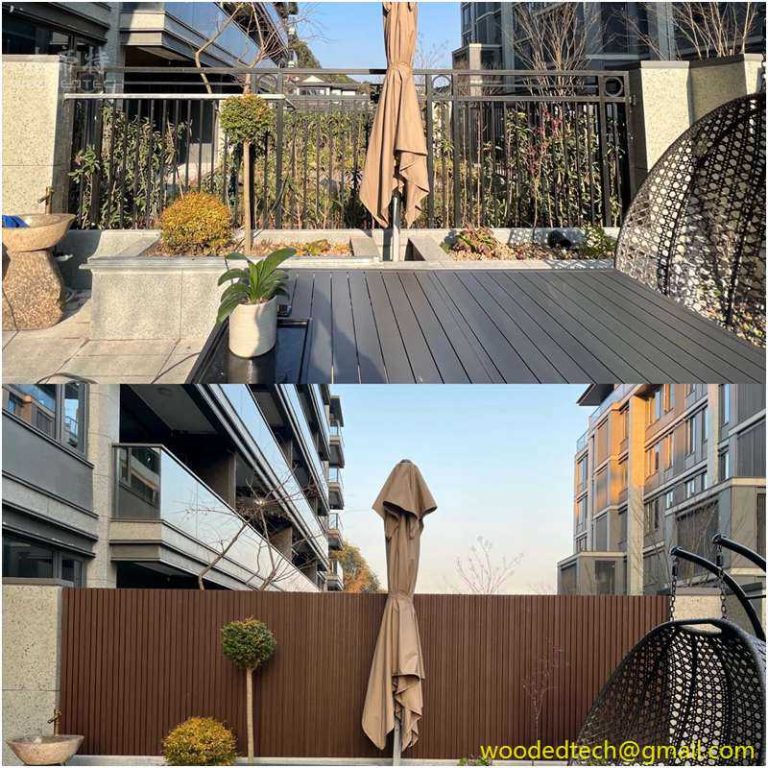

Co-extruded wpc core flooring is widely used in floor decoration in various places such as homes, hotels, shopping malls, schools, etc. It is especially suitable for use in humid environments such as kitchens, bathrooms, basements, and places with direct sunlight such as balconies and terraces.

4. Conclusion

As a green and environmentally friendly flooring product with superior performance, co-extruded wpc core flooring not only meets consumers’ needs for environmental protection, comfort, and beauty, but also leads a new trend in home decoration. Under the general trend of green home, co-extruded wpc core flooring will surely become the main force in the future flooring market.

Let us look forward to the arrival of a new era of green home!