WPC Beams: Strong and Reliable WPC Beams for Structural Support

WPC Beams: Strong and Reliable WPC Beams for Structural Support In the world of construction and structural engineering, the materials used are vital to the success and longevity of any building project. Among the various materials available, Wood Plastic Composite (WPC) beams have emerged as a strong and reliable option for structural support. WPC beams…

WPC Beams: Strong and Reliable WPC Beams for Structural Support

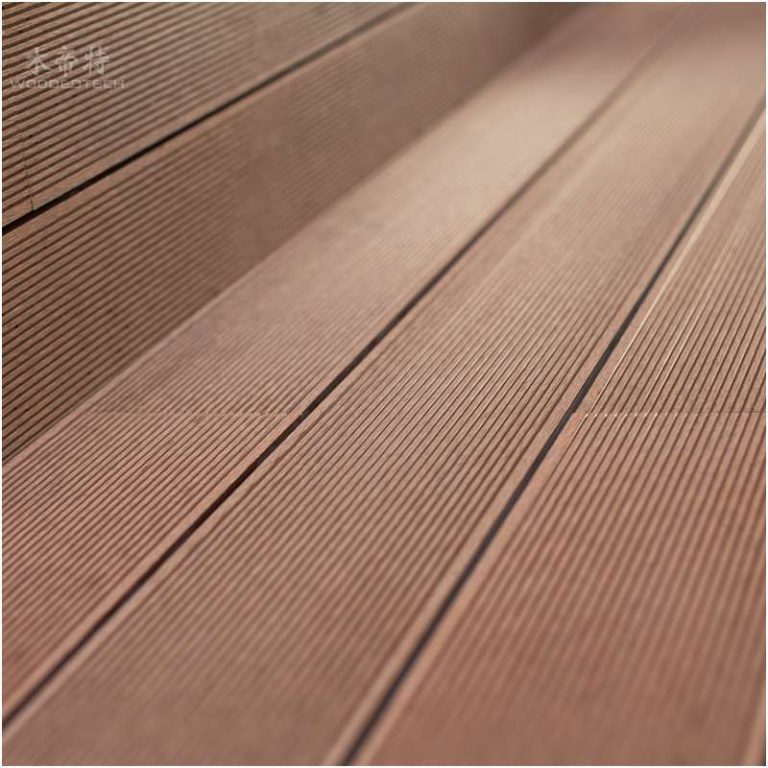

In the world of construction and structural engineering, the materials used are vital to the success and longevity of any building project. Among the various materials available, Wood Plastic Composite (WPC) beams have emerged as a strong and reliable option for structural support. WPC beams are engineered to combine the best properties of both wood and plastic, resulting in a product that not only meets the demands of modern construction but also offers a range of benefits that make it an attractive choice for builders and architects alike.

WPC is a composite material made from a mixture of wood fibers and plastic. This unique combination gives WPC beams several advantages over traditional materials such as solid wood or metal. First and foremost, WPC beams exhibit remarkable strength and durability. They are designed to withstand significant loads, making them suitable for various applications, including residential, commercial, and industrial structures. Their inherent resistance to warping, splitting, and cracking allows them to maintain their structural integrity over time, even in challenging environmental conditions.

One of the standout features of WPC beams is their low-maintenance nature. In traditional construction, wood beams often require regular treatment to protect against moisture, insects, and rot. Metal beams may rust or corrode over time, necessitating periodic coatings or replacements. In contrast, WPC beams are engineered to be maintenance-free in the later stages of their life cycle. This characteristic can lead to significant cost savings for property owners. With fewer maintenance requirements, building owners can allocate resources elsewhere, contributing to the overall efficiency of a project.

Moreover, WPC beams are eco-friendly. The wood fibers used in their production are typically sourced from recycled materials or sustainably managed forests, reducing the environmental impact associated with deforestation. The plastic component often comes from recycled plastics, further enhancing the sustainability of the material. By choosing WPC beams, builders can contribute to a greener future while ensuring that their structures are robust and reliable.

Another important aspect of WPC beams is their adaptability to various design requirements. They can be easily customized to meet specific load-bearing needs and architectural styles. WPC beams can be manufactured in different sizes, shapes, and colors, providing architects with the flexibility to create innovative designs without compromising on structural integrity. This versatility makes WPC beams an ideal choice for both traditional and modern construction projects.

In addition to their strength and design adaptability, WPC beams offer excellent thermal insulation properties. The combination of wood and plastic provides a level of insulation that can help regulate indoor temperatures, leading to enhanced energy efficiency in buildings. This characteristic can contribute to lower heating and cooling costs, making WPC beams an economically sound choice for long-term energy savings.

The installation process for WPC beams is also straightforward, which can further reduce construction time and labor costs. Their lightweight nature makes them easier to handle compared to traditional heavy materials. Builders can quickly install WPC beams, allowing projects to move forward without unnecessary delays. This efficiency is especially beneficial in fast-paced construction environments where time is of the essence.

When it comes to safety, WPC beams excel as well. They are resistant to fire, mold, and pests, reducing the risk of structural failure due to unforeseen circumstances. This fire resistance is particularly important in commercial applications where the safety of occupants is a top priority. By using WPC beams, builders can enhance the overall safety of their structures, providing peace of mind to property owners and occupants alike.

Furthermore, WPC beams offer excellent sound insulation properties. The composite material helps to dampen sound vibrations, making buildings constructed with WPC beams quieter and more comfortable. This aspect is especially valuable in urban environments where noise pollution can be a significant concern. By incorporating WPC beams into their designs, architects can create serene spaces that promote relaxation and well-being.

In summary, WPC beams represent a strong and reliable solution for structural support in modern construction. Their unique blend of wood and plastic provides exceptional strength, durability, and low maintenance requirements, making them an attractive choice for builders and property owners alike. With their eco-friendly credentials, design adaptability, excellent thermal and sound insulation properties, and straightforward installation process, WPC beams are well-suited for a wide range of applications.

As the construction industry continues to evolve and seek sustainable solutions, WPC beams stand out as a material that meets the demands of both builders and the environment. By choosing WPC beams for structural support, builders can ensure that their projects are not only robust and reliable but also contribute to a more sustainable future. The long-lasting performance and minimal maintenance needs of WPC beams make them a smart investment for any construction project, ultimately providing peace of mind for years to come.