Understand WPC Cladding Thickness for Your Building Requirements

Understand WPC Cladding Thickness for Your Building Requirements When it comes to building and construction, one of the key aspects that often gets overlooked is the choice of materials used for cladding. Among various options available in the market, Wood Plastic Composite (WPC) cladding has gained significant popularity due to its versatile properties and customizable…

Understand WPC Cladding Thickness for Your Building Requirements

When it comes to building and construction, one of the key aspects that often gets overlooked is the choice of materials used for cladding. Among various options available in the market, Wood Plastic Composite (WPC) cladding has gained significant popularity due to its versatile properties and customizable features. Understanding WPC cladding thickness is essential for meeting your specific building requirements and ensuring the longevity and aesthetic appeal of your structure.

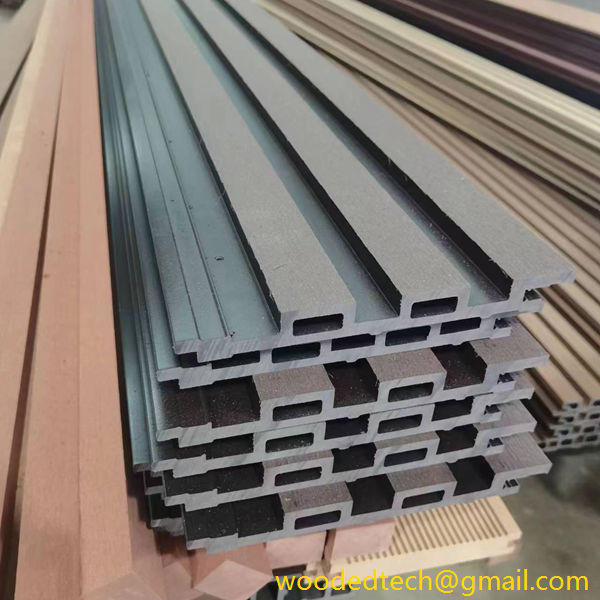

WPC cladding is a composite material made from a blend of wood fibers and plastic. This combination creates a product that mimics the appearance of natural wood while offering enhanced durability and resistance to the elements. One of the most critical factors to consider when selecting WPC cladding is its thickness. The thickness of WPC cladding can significantly affect its performance, aesthetic qualities, and suitability for various applications.

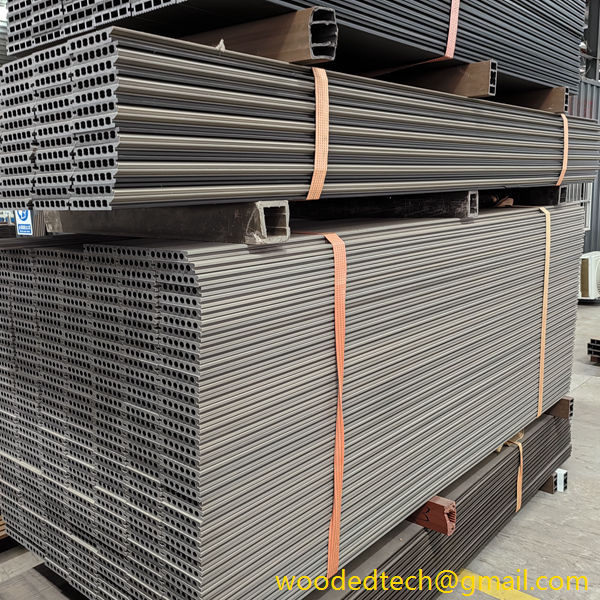

The standard thickness of WPC cladding usually ranges from 10mm to 25mm, but manufacturers often provide options outside this range. A thicker board typically offers greater strength and durability, making it ideal for high-traffic areas or buildings that experience heavy wear and tear. Thicker cladding can also provide better insulation properties, reducing heat loss in colder climates and improving energy efficiency in buildings.

When considering the thickness of WPC cladding, it is essential to take into account the specific environmental conditions your building will face. For example, in areas with high humidity or exposure to moisture, thicker WPC cladding may be necessary to prevent warping or degradation over time. Conversely, in dry climates, a thinner profile could suffice, provided that it meets your aesthetic and functional requirements.

Another critical factor to consider is the structural support available for the cladding. Thicker WPC boards may require a more robust framework to support their weight adequately. It is crucial to consult with architects or structural engineers to ensure that your building’s design can accommodate the chosen thickness of cladding. This consultation can help you avoid potential issues such as sagging or uneven surfaces, which can detract from the overall look of your building.

Aesthetic considerations also play a significant role in selecting WPC cladding thickness. Many homeowners and builders aim for a seamless and attractive finish, and the thickness can impact this appearance. Thicker boards may create a more substantial presence, lending a sense of solidity and strength to the structure. On the other hand, thinner profiles can offer a sleeker, more modern look. The choice ultimately depends on the desired style and design of the building.

Customization is one of the most significant advantages of WPC cladding. Many manufacturers offer a variety of colors, textures, and finishes that can be tailored to suit a wide range of architectural styles. Apart from the thickness, you can choose from options like smooth, embossed, or grooved finishes, allowing you to create a unique look for your building. The ability to customize not only enhances the aesthetic appeal but also allows for better integration with the surrounding environment.

In addition to thickness, the installation process of WPC cladding also deserves attention. While WPC is generally easier to install than traditional wood, the thickness can influence the installation method and tools required. Thicker panels may necessitate specialized cutting tools or additional hardware for secure attachment. It’s essential to follow the manufacturer’s recommendations for installation to ensure the longevity and performance of the cladding.

Maintenance is another important consideration when selecting WPC cladding thickness. Generally, WPC materials require less maintenance than traditional wood, as they are resistant to rot, insects, and fading. However, thicker boards may be easier to clean and maintain over time, as they can better withstand the rigors of weather exposure and wear. It is advisable to periodically inspect the cladding for any signs of damage or wear, regardless of thickness, to maintain its aesthetic appeal and structural integrity.

In summary, understanding WPC cladding thickness is crucial for meeting your building requirements. The thickness not only impacts the durability and performance of the cladding but also plays a significant role in the aesthetic appeal of your structure. With a wide range of customizable materials available, you can tailor the cladding to fit your specific needs and preferences.

When selecting the appropriate thickness for your project, consider factors such as environmental conditions, structural support, aesthetic goals, and maintenance requirements. Consulting with professionals in architecture and construction can provide valuable insights and help you make informed decisions.

In conclusion, WPC cladding is a versatile and durable option for modern construction. By understanding the implications of thickness and exploring the various customizable options available, you can ensure that your building not only meets functional requirements but also achieves the desired look and feel. With the right choice of WPC cladding, you can create a stunning and resilient exterior that will stand the test of time.