Types of Wood Plastic Composite: Understanding Different Wood Plastic Composite Types

Types of Wood Plastic Composite: Understanding Different Wood Plastic Composite Types Wood Plastic Composite (WPC) materials have gained significant popularity in various applications due to their unique blend of wood fibers and plastic. This combination not only enhances the aesthetic appeal of products but also improves their durability and resistance to weathering, making WPC an…

Types of Wood Plastic Composite: Understanding Different Wood Plastic Composite Types

Wood Plastic Composite (WPC) materials have gained significant popularity in various applications due to their unique blend of wood fibers and plastic. This combination not only enhances the aesthetic appeal of products but also improves their durability and resistance to weathering, making WPC an attractive alternative to traditional materials. Understanding the different types of Wood Plastic Composites is essential for making informed choices, whether for construction, furniture, or other applications.

The primary types of Wood Plastic Composites can be categorized based on their composition, manufacturing processes, and intended use. Each category offers distinct advantages, making them suitable for various applications.

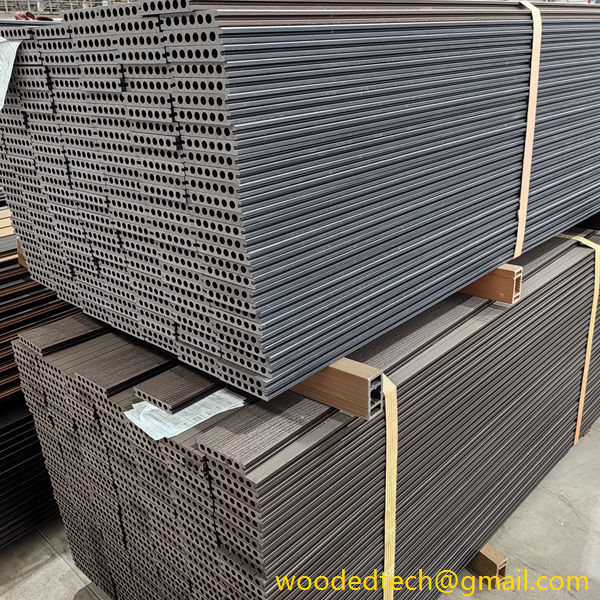

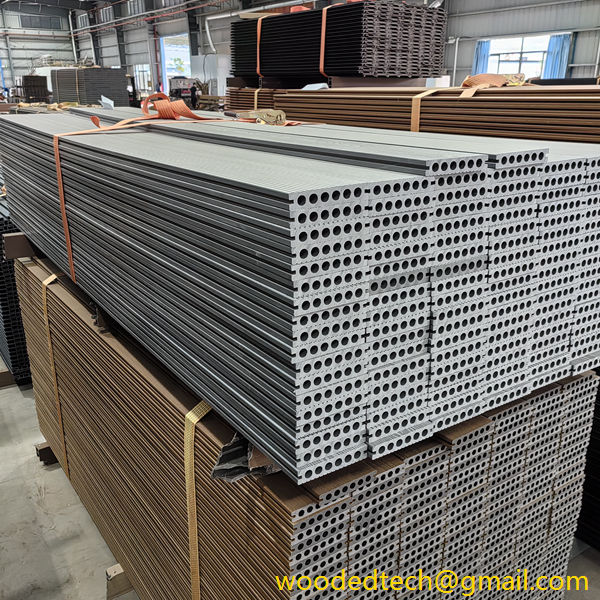

One of the most common types of Wood Plastic Composites is the extruded composite. This type is produced by combining wood fibers or flour with thermoplastic polymers through an extrusion process. The result is a continuous profile that can be cut into desired lengths for decking, railing, or other structural components. Extruded composites are known for their consistency and uniformity, which makes them a popular choice among manufacturers. They are also designed to be resistant to moisture, rot, and insects, making them ideal for outdoor applications.

Another category is molded Wood Plastic Composites. Unlike extruded composites, molded composites are created by injecting a mixture of wood fibers and plastic into a mold. This method allows for more intricate shapes and designs, making it suitable for products such as furniture, decorative panels, and custom components. The molding process also enables manufacturers to achieve a higher level of detail, which can enhance the visual appeal of the final product. Molded composites can be treated with various finishes to enhance their appearance, providing options for customization.

There are also hybrid Wood Plastic Composites that combine multiple types of plastics with wood fibers. This approach allows manufacturers to tailor the properties of the composite material to meet specific performance criteria. For example, by adding additives like UV stabilizers or colorants, manufacturers can enhance the material’s resistance to fading or improve its aesthetic appeal. Hybrid composites can be engineered for various applications, from decking to automotive components, making them versatile options in the WPC market.

In addition to the primary categories of WPC, there are also variations based on the type of wood used. Different woods can impart unique characteristics to the composite material. For instance, using hardwood fibers such as oak or maple can enhance the strength and durability of the composite, while softwood fibers like pine can contribute to a lighter weight and lower cost. The choice of wood species can also affect the visual appearance, with different grains and colors providing a range of aesthetic options.

Furthermore, the type of plastic used in the composite also plays a crucial role in determining its properties. Common plastic materials used in WPC production include polyethylene, polypropylene, and polyvinyl chloride (PVC). Each type of plastic has its advantages and limitations. For example, polyethylene-based composites are known for their flexibility and resistance to moisture, making them ideal for outdoor applications. In contrast, PVC composites are more rigid and resistant to chemical exposure, which can be beneficial in industrial settings.

Another important aspect to consider is the level of customization available in Wood Plastic Composites. Manufacturers can adjust various parameters, such as the ratio of wood to plastic, the type of additives used, and the surface finishes applied. This level of customization allows customers to select products that meet their specific needs and preferences, whether for residential, commercial, or industrial applications. For example, customers may choose a composite with a higher wood content for a more natural appearance or opt for a lower wood content for enhanced durability in high-traffic areas.

Sustainability is also a growing concern in the production of Wood Plastic Composites. Many manufacturers are now focusing on using recycled materials, both in terms of wood fibers and plastics. By incorporating recycled materials, they can reduce waste and lower the environmental impact of WPC production. This shift towards sustainability is not only beneficial for the environment but also aligns with the increasing demand for eco-friendly products among consumers.

In conclusion, understanding the different types of Wood Plastic Composites is essential for making informed decisions in various applications. From extruded and molded composites to hybrid options, the variety of WPC materials available allows for a wide range of customization. Factors such as wood species, plastic type, and manufacturing processes all contribute to the unique properties of each composite, making it possible to meet specific performance and aesthetic requirements. As the industry continues to evolve, the emphasis on sustainability and the use of recycled materials will likely play a significant role in shaping the future of Wood Plastic Composites, ensuring they remain a viable and attractive option for consumers and manufacturers alike.