Still confused between wood plastic and plastic wood ?WPC decking and PWC decking?

Still confused between wood plastic and wood plastic?WPC decking and PWC decking? The birth of new materials will inevitably bring about the birth of new forms of art design and the evolution of new lifestyles, thereby bringing a qualitative leap to people’s lives and social development. The birth of new materials is often accompanied by…

Still confused between wood plastic and wood plastic?WPC decking and PWC decking?

The birth of new materials will inevitably bring about the birth of new forms of art design and the evolution of new lifestyles, thereby bringing a qualitative leap to people’s lives and social development.

The birth of new materials is often accompanied by changes in people’s cognition, from unfamiliar to familiar.

It is not easy to accept a new thing. Therefore, many people call the pioneers, developers, and promoters of new materials heroes who are willing to endure loneliness.

This article allows more people to get closer to wood-plastic composite materials and understand wood-plastic composite materials.

Characteristics and advantages of wood-plastic composite materials (1)

The origin and original intention of wood plastic

ˆ With the development of economic life and the advancement of urbanization, timber is in great demand, which is accompanied by the continuous felling of logs. The logs are greatly reduced and the environment is damaged. The original defects of wood, such as easy moldiness, water absorption, swelling, cracking, fading, and high maintenance costs, have also led people to explore the development of new materials that have the natural and moist characteristics of wood, can replace wood, and are environmentally friendly and sustainable.

Wood-plastic composite materials emerged at the historic moment.

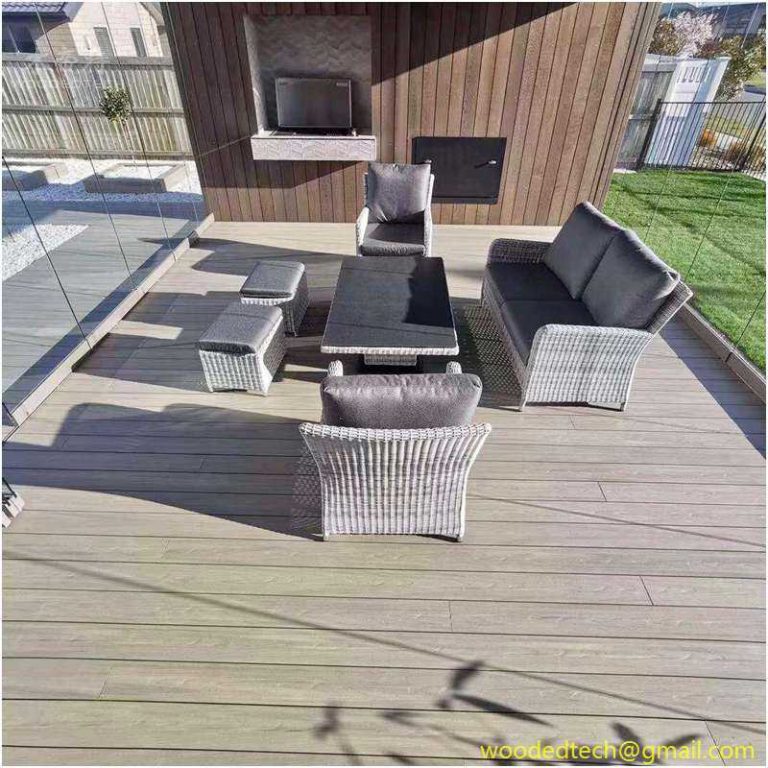

Wood-Plastic Composites (WPC) or WPC decking is a new type of composite material that has been booming at home and abroad in recent years. It refers to the use of polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc. to replace the usual The resin adhesive is mixed with more than 35%-70% of wood powder, rice husk, straw and other waste plant fibers to form new wood materials, which are then processed by extrusion, molding, injection molding and other processing techniques to produce boards or profiles. . It is not difficult to see that from the beginning of its birth, wood-plastic composite materials have been based on the upgrading, processing and recycling of waste resources.

However, as a new category of composite materials, its development process has also been tested in all aspects. Quality control must be the most critical part for public acceptance. At present, failures due to improper installation, substandard material technology, raw material problems, etc. have affected people’s understanding of wood-plastic composite materials to a certain extent. This lecture also hopes to explain this.

Wood plastic ≠ wood plastic

The English name for plastic wood is Plastic Wood, and Plastic stands for plastic, which means that this material is filled with wood powder in the plastic board, so the wood powder is only a filling function, and it is essentially plastic. The English name of wood plastic is Wood Plastic Composites, which has a completely different concept. It means that the material fiber material plays a role in reinforcing and toughening it, and is compounded with plastic to form a new type of composite material, whose essence is wood. Therefore, wood-plastic composites look like wood and have many functions and features like wood.