Selection of pigment components in co-extruded WPC decking formulas

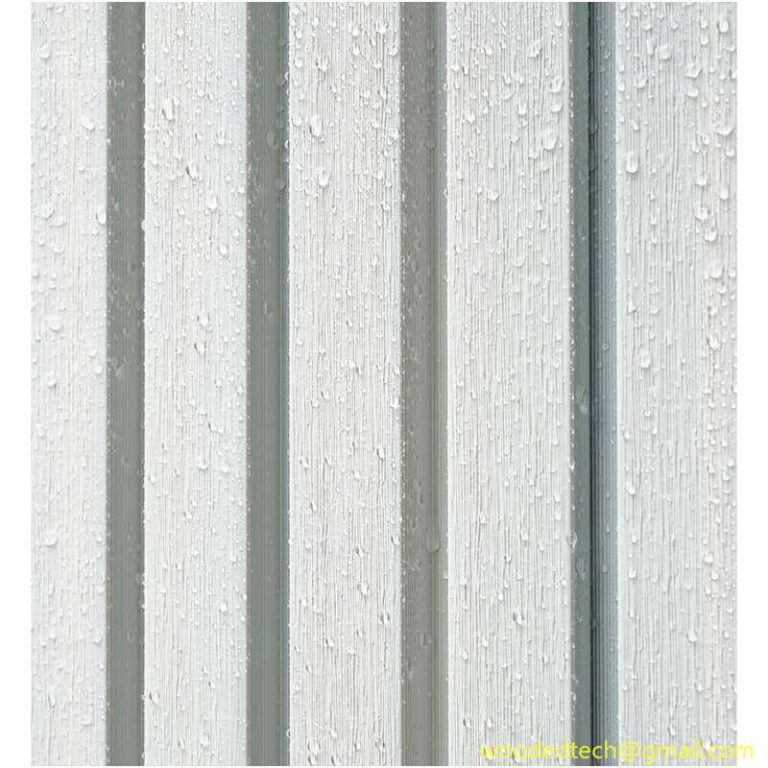

Selection of pigment components in co-extruded WPC decking formulas. Plastic wood co-extruded WPC decking is the most important type of co-extruded WPC material, accounting for more than 90%. Co-extruded WPC materials specially developed and designed for outdoor use were initially upgraded from ordinary plastic wood materials. Later, as the technology became more sophisticated and advanced,…

Selection of pigment components in co-extruded WPC decking formulas.

Plastic wood co-extruded WPC decking is the most important type of co-extruded WPC material, accounting for more than 90%. Co-extruded WPC materials specially developed and designed for outdoor use were initially upgraded from ordinary plastic wood materials. Later, as the technology became more sophisticated and advanced, more types of subdivided products evolved.

For co-extruded WPC materials, one of the development highlights of co-extruded WPC decking is a better solution to the color problem. The original ordinary plastic wood materials generally have problems such as obvious fading and dull and plain colors.

Why is the color of the original ordinary plastic wood material relatively monotonous and plain? Of course, this does not mean that it cannot be colorful or bright, which can also be achieved through the selection of pigments. However, due to the natural surrounding structure of ordinary plastic wood materials, bright and moving colors will fade more seriously.

Pigments can be distinguished from a chemical perspective and can be divided into two categories: inorganic pigments and organic pigments. These two categories have two very obvious characteristics when applied to ordinary wood-plastic materials and co-extruded wood-plastic materials. Inorganic pigments have simple and monotonous colors, but they have good weather resistance and strong UV resistance. Inorganic pigments can produce bright and attractive colors, but their weather resistance is slightly poor, especially ordinary plastic wood materials, which have poor UV resistance and serious fading.

Since ordinary wood-plastic materials are homogeneous composite materials, the surface layer and core layer materials are consistent. Pigments are evenly dispersed in the material and also on the surface of the material. Therefore, ultraviolet rays from the sun can directly reach the surface and affect the working performance of the pigments. As an inorganic pigment, its structure is composed of extremely small molecules. Ultraviolet irradiation will basically not cause any damage to its molecular structure, so it is difficult to have much impact on its apparent color. Therefore, most of the colors of inorganic pigments used in ordinary plastic wood materials It is relatively stable and has good weather resistance. Of course, there is less fading. This is normal. This is a phenomenon manifested by the loss of pigment molecules on the surface of the material. When the material and the surrounding environment become balanced, the color can remain stable for a long time. This process is roughly There are three months. Organic pigments are different. Their molecular structure is easily damaged by ultraviolet radiation and decomposes, which is manifested as surface color changes. And because wood powder accounts for a large proportion of ordinary wood plastic materials, wood powder cannot destroy organic pigment molecules. Effective anti-ultraviolet protection, so when ordinary wood-plastic materials use organic pigments, they fade seriously. It is rare to see the use of organic pigments to produce ordinary wood-plastic materials on the market today.

Unlike plastic-wood co-extrusion materials, plastic-wood co-extrusion flooring, as a high-end outdoor floor, must focus on this issue. Wood-plastic co-extrusion materials are divided into two-layer structures, a core layer and a co-extrusion layer. The co-extrusion layer generally uses plastic modification to obtain the formula composition of the co-extrusion layer according to the target performance requirements. When the formulation technology and production technology of plastic-wood co-extrusion materials were relatively weak at the beginning, for the sake of long-term use, most manufacturers still based on the most durable inorganic pigments for the color ratio of plastic-wood co-extrusion materials. , the color of most plastic wood co-extruded floors on the market today is also adjusted by inorganic pigments.

However, with the extensive promotion and application of wood-plastic co-extrusion materials in the past two years, production technology and product formula technology have become more and more sophisticated. Gradually using plastic modification technology and boldly introducing organic pigments are inevitable for market development. Organic pigments can enrich the color gamut that can be produced and debugged, and can make the target effect more adjustable and expandable. This is a very personalized performance. Of course, the premise is that the improvements in production technology and product formulation technology are enough to offset the damage to organic pigment molecules caused by direct ultraviolet rays on the surface.