plastic wood flooring price

plastic wood flooring price Exploring the price difference of outdoor plastic wood flooring: revealing the secrets of raw materials, process, and quality control In the context of the increasing popularity of environmental protection concepts today, outdoor plastic wood flooring has gradually become a flooring material widely used in various outdoor scenes with its green, environmentally…

Exploring the price difference of outdoor plastic wood flooring: revealing the secrets of raw materials, process, and quality control

In the context of the increasing popularity of environmental protection concepts today, outdoor plastic wood flooring has gradually become a flooring material widely used in various outdoor scenes with its green, environmentally friendly and beautiful characteristics. However, the prices of outdoor plastic wood flooring on the market vary greatly, which makes people confused when choosing. This article will reveal the reasons behind the price differences from the aspects of outdoor plastic wood flooring series, cross-sectional design, raw materials, processing technology, product positioning and quality control.

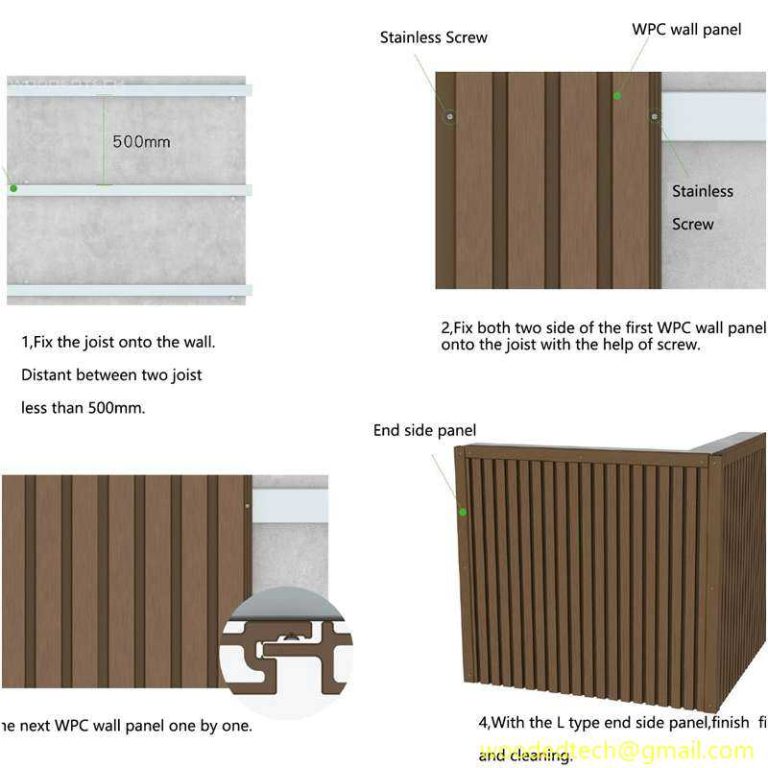

1. Outdoor plastic wood flooring series and cross-sectional design

1. Rich series to meet different needs

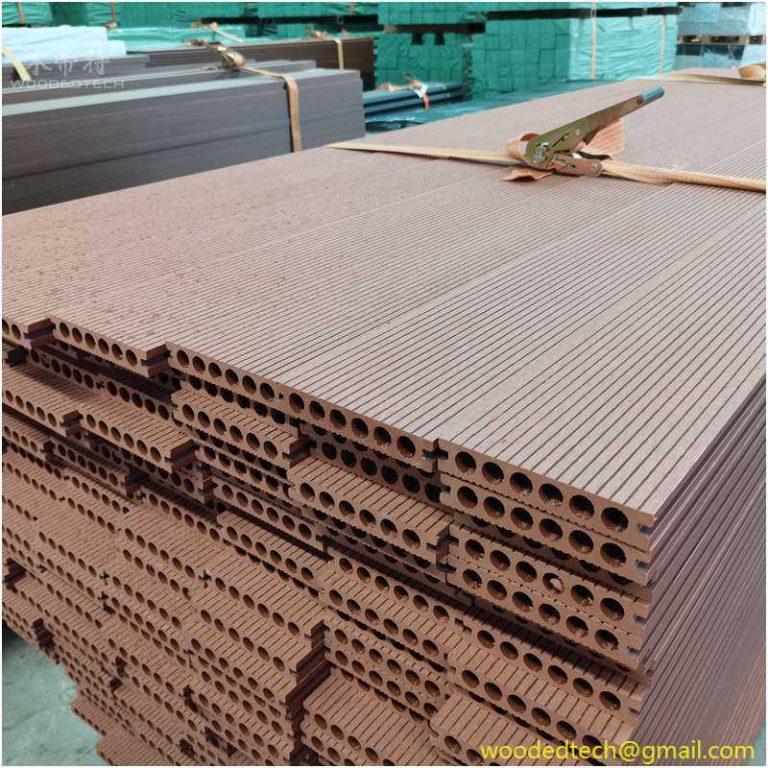

There are many series of outdoor plastic wood flooring, including but not limited to solid flooring, hollow flooring, spliced flooring, etc. Different series of floors have their own characteristics in terms of performance, aesthetics, applicable scenarios, etc. Consumers can choose according to actual needs.

2. Differences in cross-sectional design

The cross-sectional design of outdoor plastic wood flooring is also divided into solid and hollow. Solid flooring has higher compressive strength and stability, and is suitable for high-load occasions; hollow flooring is lighter, easy to install, and suitable for general scenarios. Different cross-sectional designs naturally result in different costs and prices.

2. Raw materials and processing technology

1. Raw material differences

The raw materials of outdoor plastic wood flooring are mainly divided into plastic and wood powder, among which plastics include PE, PVC, etc. Floors with different raw materials vary in performance, environmental protection, price, etc. Generally speaking, high-quality raw materials have higher costs, but longer service life and higher cost performance.

2. Processing technology differences

Processing technology is an important factor affecting the price of outdoor plastic wood flooring. High-quality flooring adopts high-temperature and high-pressure molding technology to make the floor have better compressive strength, anti-aging performance and stability. Some low-cost floors use simple hot pressing technology, and their performance is relatively poor.

3. Product positioning and quality control

1. Product positioning differences

The product positioning differences of outdoor plastic wood flooring are mainly reflected in brand image, quality assurance, after-sales service, etc. Well-known brands of flooring are more guaranteed in terms of quality and after-sales service, and the price is relatively high; while some small brands or miscellaneous brands of flooring are lower in price, but the quality and after-sales service are difficult to guarantee.

2. Differences in quality control

Quality control is the key factor in the price difference of outdoor plastic wood flooring. High-quality flooring strictly controls raw materials, processes, testing and other links in the production process to ensure product quality; while low-cost flooring often ignores quality control, resulting in unstable product performance and short service life.

IV. Summary

The price difference of outdoor plastic wood flooring is mainly determined by factors such as raw materials, processing technology, product positioning and quality control. When purchasing, consumers should consider all factors comprehensively and choose products with high cost performance. Here are some suggestions:

1. Choose a well-known brand to ensure quality and after-sales service;

2. Understand the raw materials and processing technology of the product, and pay attention to environmental protection performance;

3. Flooring with strict quality control has a longer service life;

4. Choose the appropriate series and cross-sectional design according to actual needs.

In short, when purchasing outdoor plastic wood flooring, consumers should pay attention to the comprehensive performance of the product, rather than just pursuing low prices. Through the revelations in this article, I hope you can be more wise when purchasing outdoor plastic wood flooring.