New production technology for co-extruded wood plastic composite decking(WPC decking)

New production technology for co-extruded wood plastic composite decking(WPC decking) Plastic wood profiles are mainly made of wood fiber as the basic material, thermoplastic polymer materials (plastics) and additives. After the thermoplastic polymer materials are evenly mixed, they are then coated on the surface of the profile by mold equipment and extruded. Chenggao’s new plastic…

New production technology for co-extruded wood plastic composite decking(WPC decking)

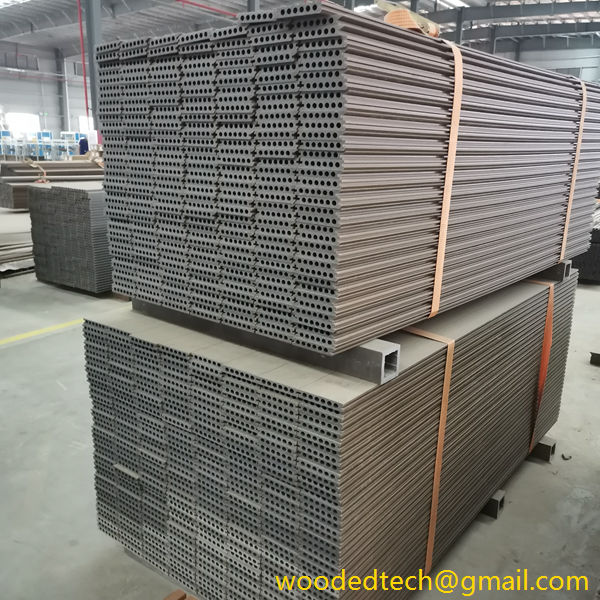

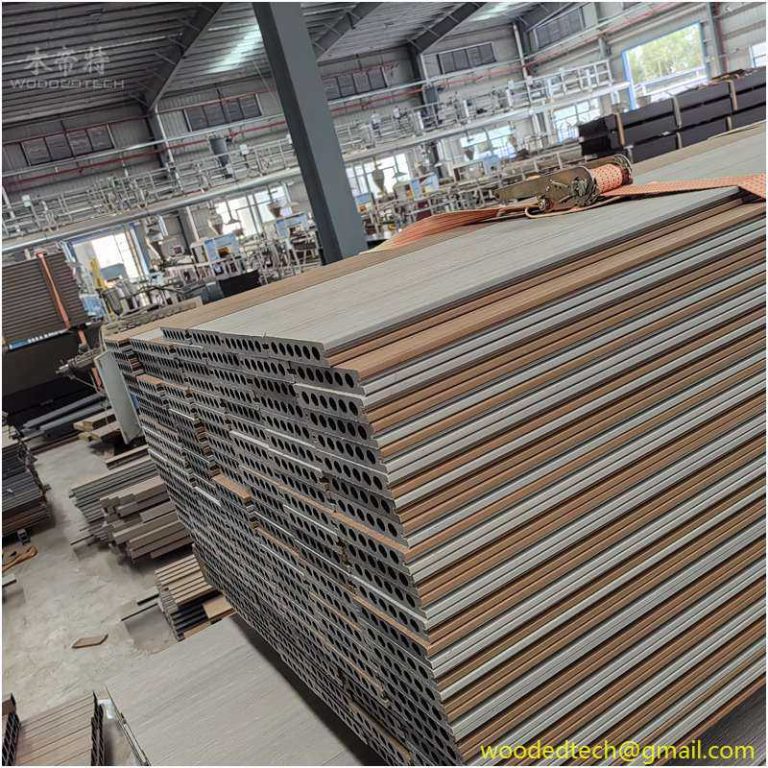

Plastic wood profiles are mainly made of wood fiber as the basic material, thermoplastic polymer materials (plastics) and additives. After the thermoplastic polymer materials are evenly mixed, they are then coated on the surface of the profile by mold equipment and extruded. Chenggao’s new plastic wood profiles have the properties and characteristics of wood and plastic, and are new composite materials that can replace wood and plastic.

During the use of the current mold, the thermoplastic polymer material will have uneven flow after being introduced into the mold cavity, resulting in a rough surface formed by the thermoplastic polymer material on the wood, and poor water cooling effect will cause the surface to be deformed. . Some companies have proposed a production line for plastic-wood co-extrusion profiles (WPC decking ) and its production process, which solves the problem in the prior art that the surface of the plastic layer of plastic-wood profiles is rough during production. Its principles and effects are as follows:

- When the co-extrusion mold is used to produce plastic-wood co-extrusion profiles, the core body is first transported to the feed port and mold cavity of the co-extrusion mold through the conveyor device. At the same time, the plastic supply device passes through the channel and extruders in sequence. The gap connecting the extrusion cavity and the thermoplastic polymer material is introduced into the extrusion cavity, and the thermoplastic polymer material will be coated on the surface of the core body to form a plastic layer. When thermoplastic polymer materials enter the extrusion cavity through channels and gaps, the gaps can make the thermoplastic polymer materials more uniform when entering the extrusion cavity, ensuring that the thermoplastic polymer materials flow into the extrusion cavity evenly and synchronously. Thermoplastic The polymer material forms a fine and smooth plastic layer on the surface of the core body, which solves the problem of rough surface of the plastic layer of plastic-wood co-extruded profiles.

- The co-extrusion mold is divided into three parts. The upper mold, lower mold and end mold are all connected together by bolts to form the co-extrusion mold. The end mold is provided with a feed cavity and a plastic flow channel. An extrusion cavity is formed between the upper mold and the lower mold. The core enters the extrusion cavity through the feed cavity, and the thermoplastic polymer material passes through the plastic flow channel. The thermoplastic polymer material is coated on the surface of the core body in the extrusion cavity and forms a plastic layer.

- The feed cavity is surrounded by an annular edge. The outer wall of the annular edge is inclined and the end away from the feed port is inclined inward, so that the thermoplastic polymer material can flow into the extrusion cavity through the annular gap in all directions and evenly. , and coat the surface of the core body to form a plastic layer.

- The channel includes an inlet plastic runner set on the end mold for transporting plastic, and the inlet plastic runner is connected to the plastic supply device. The inlet plastic runner is connected to the extrusion cavity through the split runner, the gap, and the split flow. The channel will evenly shunt the thermoplastic polymer material entering the plastic flow channel, so that the thermoplastic polymer material can evenly flow into the extrusion cavity through the surrounding gap, and a uniform formation will be formed on the surface of the core body in the extrusion cavity. And the smooth plastic layer can make the air-tightness and waterproofness of the plastic-wood co-extruded profile better. The shunt runner is set on the side where the cavity mold and the end mold are in contact and surrounds the periphery of the extrusion cavity. The inlet plastic runner passes through the main shunt path, several shunt branches, overflow channels, gaps and extrusion molds in sequence. The cavity is connected, so material can be supplied to the extrusion cavity from all directions, which avoids the situation where the plastic layer is not smooth or cannot completely cover the core due to uneven supply, so that a uniform layer can be formed on the surface of the core Plastic layer.

- The plastic layer is a thermoplastic polymer material that is formed on the surface of the core at high temperature. Therefore, it needs to be cooled after the plastic layer is formed. In the existing technology, air cooling or water cooling is mostly performed after the profile is transported out of the mold. After the mold is transported out of the mold, it is water-cooled. At this time, the temperature of the plastic layer is still high, it is easy to deform, and the cooling effect is poor. Therefore, during the transportation process, it may cause deformation or pitting on the surface, affecting the quality of the profile. In the present invention, a water-cooling channel is provided on the co-extrusion mold. The water-cooling channel includes a plurality of interconnected upper channels and lower channels, so the cooling area is larger. The upper channels and lower channels are respectively arranged on the upper and lower sides of the extrusion cavity. Therefore, it can have a good cooling effect on the profile in the extrusion cavity, and the plastic layer will not be deformed or pitted, so that the plastic layer can form a smooth surface layer on the core surface. One end of the lower channel closest to the contact surface is connected to the water inlet pipe, the upper channel far away from the contact surface is connected to the water outlet pipe, and the two ends of the remaining upper channels and lower channels are connected through the first connecting pipe respectively, so that several upper channels and several lower channels are connected. The channels can be connected, and the water inlet pipe and the water outlet pipe are connected to the water storage tank, so water can circulate between the water storage tank and the water cooling channel, which has a good cooling effect on the plastic wood co-extruded profile. The inlet plastic flow channel is connected to a plastic supply device. The plastic supply device can provide thermoplastic polymer materials for the production process of plastic-wood co-extrusion profiles to form a plastic layer on the surface of the core body.

- The core body is transported into the extrusion cavity connected to the feed port through the core body conveying device. After starting the drive motor, the two roller conveyor belts will start driving at the same time, thereby driving the core body in the core body conveying channel to the extrusion cavity. Feed port movement.

- After the surface of the core body is covered with a plastic layer to form a plastic-wood co-extruded profile, it is initially cooled by a water-cooling channel. After the co-extrusion cavity is extruded, it will be further cooled and shaped by a water-cooling tank. The spray device on one side of the water-cooling tank will spray the plastic-wood co-extruded profiles in the water-cooling tank to achieve cooling and shaping of the plastic-wood co-extruded profiles, ensuring that the plastic layer covering the core is smooth and even, and will not deform or Pockets appear.

- After the core is transported into the extrusion cavity, the plastic is also transported into the extrusion cavity to cover the surface of the core, forming a plastic layer on the surface of the core. Since the temperature of the plastic is relatively high, it is formed After the plastic layer, cooling water is first introduced into the water-cooling channel to preliminarily cool the plastic-wood co-extruded profile. After the preliminary cooling, the plastic-wood co-extruded profile will be extruded by the core body located behind it into the water-cooling tank. The shower pipe sprays for further cooling and shaping to ensure that the plastic layer is uniform and the surface is smooth.