Modern Wood Plastic Cladding Solutions for Contemporary Designs

Modern Wood Plastic Cladding Solutions for Contemporary Designs In recent years, the construction and architectural industries have witnessed a significant shift towards sustainable and innovative materials. One of the most promising advancements in this field is the development of wood plastic composite (WPC) cladding. This modern solution combines the aesthetic appeal of wood with the…

Modern Wood Plastic Cladding Solutions for Contemporary Designs

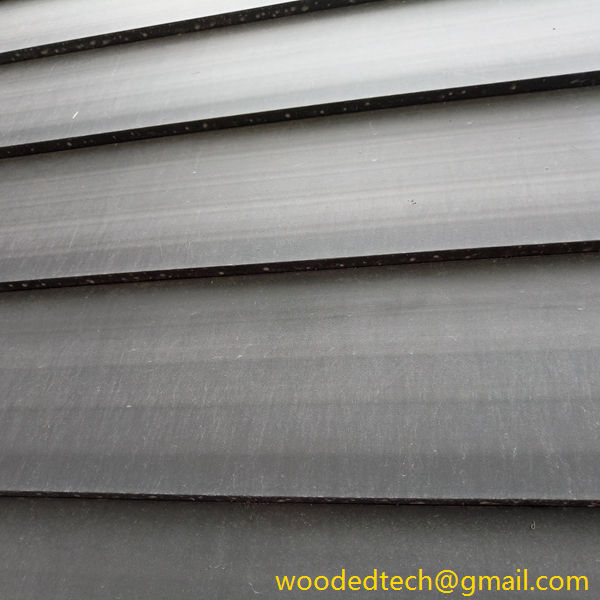

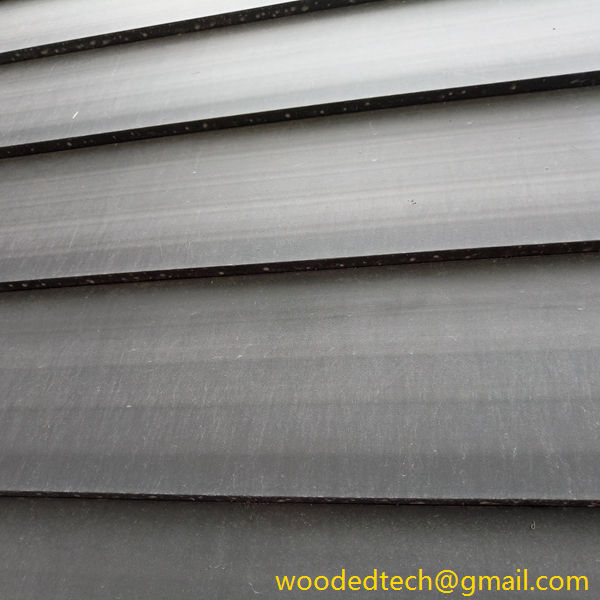

In recent years, the construction and architectural industries have witnessed a significant shift towards sustainable and innovative materials. One of the most promising advancements in this field is the development of wood plastic composite (WPC) cladding. This modern solution combines the aesthetic appeal of wood with the durability and low maintenance of plastic, offering an attractive option for contemporary designs. As global production capacity for WPC continues to grow, it is essential to explore how this material is transforming the cladding landscape and the implications for design, sustainability, and global trade.

Wood plastic composites are created by blending wood fibers or flour with thermoplastics, such as polyethylene or polypropylene. The result is a versatile material that retains the natural look and feel of wood while boasting superior resistance to weather, insects, and rot. This innovative solution has gained popularity in various applications, from residential buildings to commercial structures and public spaces. The modern architectural trend leans towards clean lines, open spaces, and a seamless integration of indoor and outdoor environments. WPC cladding supports these design principles by providing a sleek finish that complements contemporary aesthetics.

One of the key advantages of WPC cladding is its sustainability. With growing concerns about deforestation and environmental degradation, the construction industry is increasingly seeking eco-friendly materials. WPC is often manufactured using recycled wood and plastic materials, significantly reducing the carbon footprint associated with traditional cladding options. Furthermore, the durability of WPC contributes to its sustainability profile, as it requires less frequent replacement or maintenance, thereby conserving resources over time. As architects and builders prioritize sustainability in their projects, WPC cladding has emerged as a frontrunner in eco-conscious design.

The global distribution of production capacity for wood plastic composites reflects the material’s rising prominence. Several countries have established themselves as leaders in the WPC market, with advanced manufacturing facilities and access to raw materials. The United States, for example, has a robust production capacity driven by a combination of technological innovation and a strong demand for sustainable building materials. European countries, particularly Germany and Sweden, are also significant players in the WPC sector, leveraging their expertise in both wood processing and recycling technologies.

China has emerged as a major manufacturer of WPC, primarily due to its low labor costs and extensive manufacturing capabilities. The country’s production capacity has allowed it to become a significant exporter of WPC products worldwide. As global trade continues to evolve, the dynamics of WPC production are likely to shift, with emerging markets in Asia and Latin America also starting to invest in WPC technology. The expansion of production capacity in these regions can lead to increased competition, potentially resulting in lower prices and more diverse product offerings for consumers.

The growth of WPC cladding is also influenced by changes in consumer preferences and building regulations. As homeowners and developers increasingly seek low-maintenance, long-lasting materials, the demand for WPC is expected to continue rising. Moreover, as building codes become more stringent regarding sustainability and energy efficiency, WPC cladding meets these requirements effectively. Its insulating properties contribute to energy-efficient building designs, making it an appealing option in a market that prioritizes both aesthetics and functionality.

Innovation in WPC technology is another driving force behind the material’s growing popularity. Manufacturers are continuously working to enhance the properties of WPC, developing formulations that improve color retention, resistance to fading, and overall performance. The introduction of advanced manufacturing techniques, such as co-extrusion, has enabled producers to create WPC products with enhanced surface durability and aesthetics. These innovations not only improve the product quality but also expand the design possibilities for architects and designers, allowing for a wider range of finishes, colors, and textures.

Despite its many advantages, the adoption of WPC cladding is not without challenges. Some consumers remain skeptical about the longevity and performance of composite materials compared to traditional wood. Education and awareness campaigns are crucial in addressing these concerns and highlighting the benefits of WPC. Furthermore, as the market for WPC continues to grow, manufacturers must navigate issues related to quality control and product consistency to maintain consumer trust.

The global production capacity distribution for WPC cladding will likely continue to evolve as demand increases and new technologies emerge. As more countries recognize the benefits of sustainable building materials, investment in WPC production facilities may become more widespread. This shift will not only enhance the availability of WPC products but also promote regional economic development and job creation in the manufacturing sector.

In conclusion, modern wood plastic cladding solutions represent a significant advancement in contemporary architectural design. With their unique blend of aesthetic appeal, durability, and sustainability, WPC products are poised to play a crucial role in the future of building materials. The ongoing expansion of global production capacity reflects the material’s rising prominence and the industry’s commitment to innovation and sustainability. As architects, builders, and consumers continue to embrace WPC cladding, it is clear that this modern solution will shape the landscape of contemporary design for years to come.