Length of Composite Deck Boards: What You Need to Know

Length of Composite Deck Boards: What You Need to Know Composite decking has gained immense popularity in recent years due to its durability, low maintenance requirements, and the aesthetic appeal it offers. Homeowners and builders alike are increasingly choosing composite deck boards as a viable alternative to traditional wood decking. One of the most critical…

Length of Composite Deck Boards: What You Need to Know

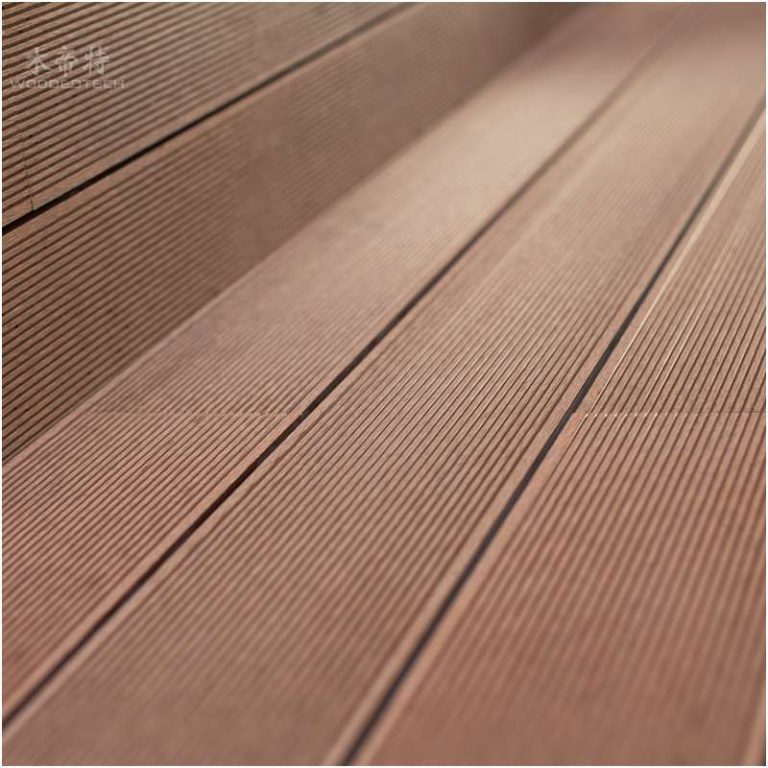

Composite decking has gained immense popularity in recent years due to its durability, low maintenance requirements, and the aesthetic appeal it offers. Homeowners and builders alike are increasingly choosing composite deck boards as a viable alternative to traditional wood decking. One of the most critical factors to consider when selecting composite deck boards is their length. In this article, we will explore the importance of board length, the variations available in the market, and the cost advantages associated with production in China.

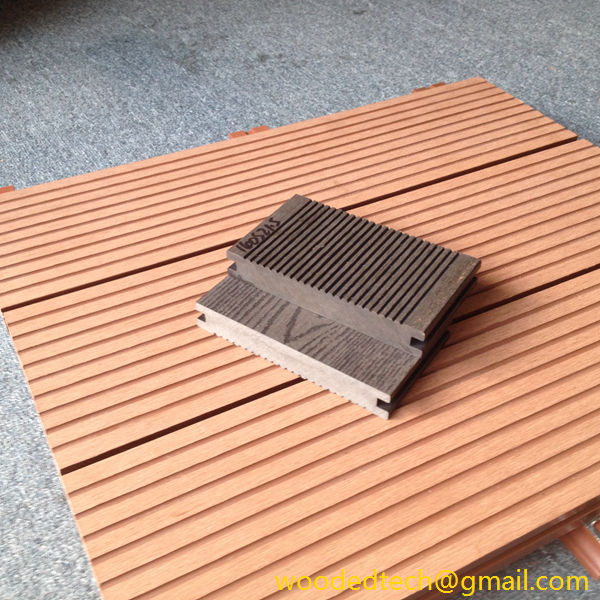

When it comes to composite deck boards, length is a vital aspect to consider. Standard lengths typically range from 12 to 20 feet, with some manufacturers offering customization options. Homeowners should consider the size of their decks and the layout when selecting the appropriate board lengths. Longer boards may reduce the number of seams and joints in the deck, creating a more visually appealing surface. Additionally, longer boards can minimize waste during installation, as fewer cuts are needed.

One of the primary benefits of using composite decking is its longevity. Unlike traditional wood, composite materials are resistant to rot, splintering, and insect damage. This durability makes composite boards an attractive investment for homeowners looking to build a long-lasting outdoor space. When considering length, it is essential to note that longer boards may offer increased stability and resistance to warping over time. This characteristic can be particularly beneficial in regions with extreme weather conditions.

In terms of cost, the length of composite deck boards can significantly impact the overall expense of your decking project. Longer boards may cost more upfront, but they can lead to savings in the long run. The reduction in seams and joints means fewer materials are required for installation, which can lead to lower labor costs. Furthermore, less waste during the cutting process can contribute to overall cost savings.

From a market perspective, many consumers are increasingly aware of the advantages offered by Chinese production areas in the composite decking industry. China has established itself as a global leader in manufacturing composite materials, thanks to its advanced technology, efficient production processes, and cost-effective labor. These factors have allowed Chinese manufacturers to produce high-quality composite deck boards at competitive prices, making them an attractive option for builders and homeowners alike.

The cost advantages of sourcing composite deck boards from China can be attributed to several factors. First and foremost, the labor costs in China are generally lower than in many Western countries. This cost differential allows manufacturers to produce composite decking at a fraction of the price, which can be passed on to consumers. Additionally, China has invested heavily in modern manufacturing facilities that utilize advanced machinery and techniques, increasing productivity and reducing production costs further.

Another significant advantage of Chinese production is the availability of raw materials. China is home to abundant resources required for composite manufacturing, such as wood fibers and plastic resins. The accessibility of these materials not only streamlines the supply chain but also reduces transportation costs. Consequently, manufacturers can offer competitive pricing while maintaining high-quality standards.

The Chinese composite decking industry is also characterized by flexibility and responsiveness to market demands. Manufacturers are able to quickly adapt to changing consumer preferences and trends, providing a wide range of lengths, colors, and textures. This adaptability is particularly important in an industry where aesthetics and design play a crucial role in consumer decision-making.

To further illustrate the cost advantages of Chinese production, consider the overall lifecycle cost of composite decking. While the initial investment may be higher for longer boards, the long-term benefits far outweigh these upfront expenses. The durability and low maintenance of composite materials mean that homeowners will spend less on repairs, replacements, and upkeep over time. Additionally, the reduced environmental impact of composite decking, due to its recyclable materials and longer lifespan, can be a selling point for environmentally conscious consumers.

When selecting composite deck boards, it is also essential to consider the certifications and standards that manufacturers adhere to. Reputable Chinese manufacturers often comply with international quality standards, ensuring that their products meet safety and durability requirements. Homeowners should look for certifications such as the American Wood Protection Association (AWPA) standards or the International Code Council (ICC) certification, as these can provide peace of mind regarding the quality of the product.

In conclusion, the length of composite deck boards is a critical factor that homeowners and builders must consider when planning a decking project. While longer boards can offer numerous advantages, such as reduced seams and increased stability, the cost implications are equally important. The production advantages found in China, including lower labor costs, abundant raw materials, and advanced manufacturing capabilities, have made Chinese composite deck boards an appealing option for consumers seeking affordability without compromising quality. By carefully weighing the options available in the market, homeowners can make informed decisions that will enhance their outdoor living spaces for years to come.