Learn About WPC Panel Edge Treatments for a Polished Look

Learn About WPC Panel Edge Treatments for a Polished Look WPC, or Wood Plastic Composite, panels have gained significant popularity in modern interior design and construction due to their versatility, sustainability, and aesthetic appeal. One of the crucial aspects of achieving a polished and refined look in any WPC application is the treatment of panel…

Learn About WPC Panel Edge Treatments for a Polished Look

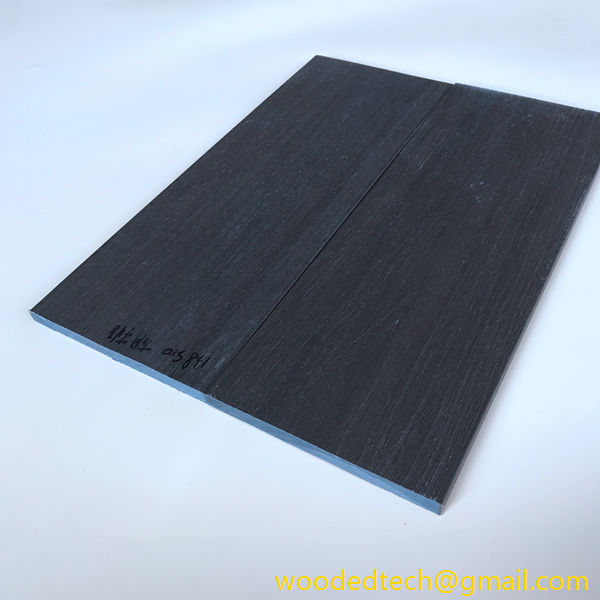

WPC, or Wood Plastic Composite, panels have gained significant popularity in modern interior design and construction due to their versatility, sustainability, and aesthetic appeal. One of the crucial aspects of achieving a polished and refined look in any WPC application is the treatment of panel edges. Understanding the various edge treatment options available can greatly enhance the visual appeal of your project while also contributing to the durability and longevity of the materials used.

Edge treatments for WPC panels serve multiple purposes. First and foremost, they contribute to the overall aesthetics of the panels. Clean, well-finished edges can make a significant difference in the appearance of furniture and architectural installations. When edges are treated properly, they can create a seamless and finished look that elevates the entire design. In contrast, untreated or poorly finished edges can detract from the overall quality of the installation, making it appear less professional or even unfinished.

There are several types of edge treatments that can be applied to WPC panels, each offering distinct advantages. One of the most common methods is the use of edge banding. Edge banding involves applying a thin strip of material, often made from PVC or melamine, to the exposed edges of the WPC panels. This not only provides a finished look but also protects the edges from moisture and wear. The choice of edge banding material can greatly influence the overall aesthetic of the panel, as there are numerous colors and textures available to match or complement the main panel.

Another popular edge treatment method is routing. Routing involves using a specialized tool to create a rounded or beveled edge along the panel’s perimeter. This technique adds a sense of sophistication and elegance to the panels, making them more visually appealing. Routed edges can also help to reduce the risk of chipping or splintering, which is particularly important in high-traffic areas or for furniture that will see regular use.

For those seeking a truly high-end finish, veneering is an option worth considering. Veneering involves applying a thin layer of real wood to the edges of the WPC panels, providing an authentic wooden appearance. This technique is particularly popular in luxury applications, where the richness of natural wood can make a substantial difference in the overall design. The beauty of veneered edges is that they combine the benefits of WPC’s durability with the timeless appeal of wood, making them an excellent choice for discerning designers and homeowners.

In addition to aesthetic considerations, edge treatments also play a vital role in the durability of WPC panels. Exposed edges are susceptible to moisture infiltration, which can lead to swelling, warping, and ultimately, structural failure. By treating edges with appropriate materials, you can create a barrier that protects against moisture and extends the lifespan of your panels. This is especially critical in areas with high humidity or where the panels may be exposed to spills and splashes, such as kitchens and bathrooms.

Furthermore, edge treatments can contribute to the overall safety of the installation. Sharp edges can pose a risk of injury, particularly in environments where children or pets are present. By opting for rounded or beveled edges, you can create a safer environment while also enhancing the visual appeal of the panels. Safety should always be a consideration in design, and edge treatments are an effective way to address this concern.

It is also important to consider the environmental impact of your edge treatment choices. Many manufacturers now offer sustainable options for edge banding and finishing materials, allowing you to make choices that align with eco-friendly practices. By selecting materials that are sourced responsibly and produced with minimal environmental impact, you can contribute to a more sustainable future while still achieving a polished and refined look for your WPC panels.

Another factor to take into account is the ease of installation and maintenance of the edge treatments. Some methods may require specialized skills or tools, which can impact the overall cost and feasibility of a project. It is essential to choose edge treatments that not only align with your aesthetic goals but are also practical for your specific application. Consulting with professionals or conducting thorough research can help you navigate these considerations effectively.

In conclusion, WPC panel edge treatments are a critical component of achieving a polished look in any design project. With options ranging from edge banding and routing to veneering, there are numerous ways to enhance the aesthetics and durability of your panels. Proper edge treatment not only elevates the visual quality of your installation but also protects against moisture and wear, ensuring that your project stands the test of time. As you embark on your design journey, take the time to explore the various edge treatment options available, and choose those that best align with your vision, values, and practical needs. With thoughtful consideration and attention to detail, you can create spaces that are not only beautiful but also functional and enduring.