Innovative Plastic Composite Panels for Modern and Eco-Friendly Building and Design Projects

Innovative Plastic Composite Panels for Modern and Eco-Friendly Building and Design Projects In recent years, the construction and design industries have witnessed a transformative shift towards sustainability and innovation, leading to the increasing popularity of plastic composite panels. These advanced materials are not only lightweight and durable but also offer a range of aesthetic and…

Innovative Plastic Composite Panels for Modern and Eco-Friendly Building and Design Projects

In recent years, the construction and design industries have witnessed a transformative shift towards sustainability and innovation, leading to the increasing popularity of plastic composite panels. These advanced materials are not only lightweight and durable but also offer a range of aesthetic and functional benefits that make them ideal for modern building projects. As the demand for eco-friendly solutions grows, the global production capacity of plastic composite panels is evolving, reflecting a shift in manufacturing practices, resource allocation, and environmental considerations.

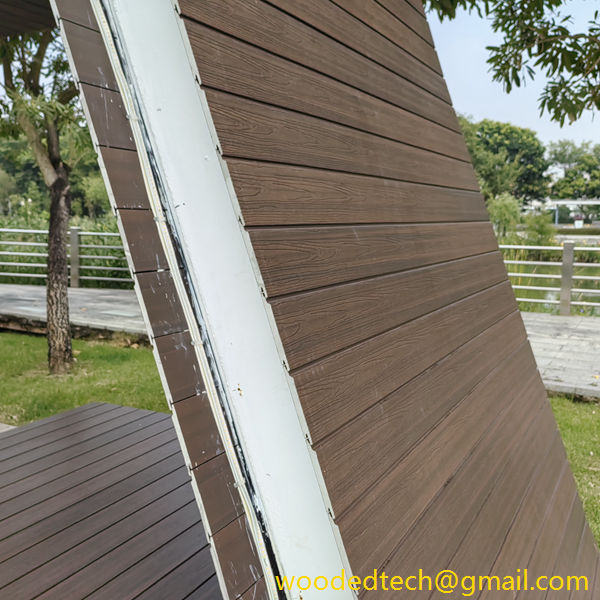

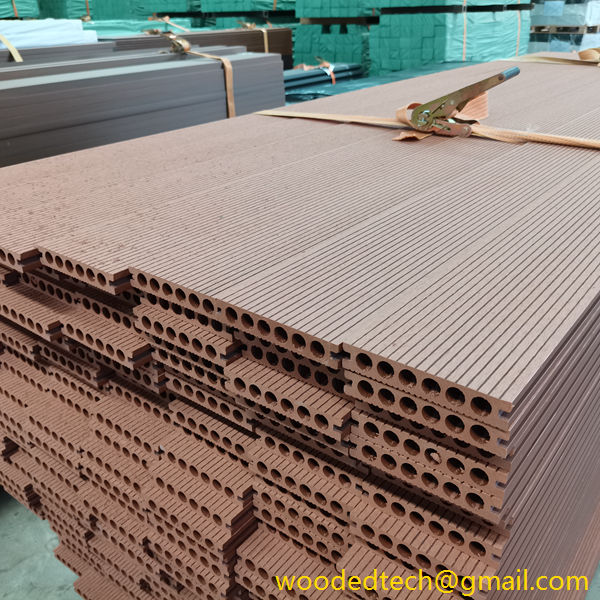

Plastic composite panels are engineered materials composed of a combination of polymers and other materials, such as wood fibers or minerals. This unique composition allows them to combine the best properties of both plastics and traditional construction materials. They are resistant to moisture, rot, and insects, which significantly enhances their lifespan compared to conventional materials. Additionally, these panels can be produced in various colors, textures, and finishes, making them sui

One of the primary advantages of plastic composite panels is their eco-friendliness. Many manufacturers are now incorporating recycled materials into their products, which helps reduce waste and lower the carbon footprint associated with production. This aligns with the global push for sustainable building practices, as architects and designers increasingly seek materials that contribute to green building certifications and eco-conscious designs. The use of recycled content not only conserves natural resources but also promotes a circular economy within the construction industry.

The distribution of global production capacity for plastic composite panels is influenced by various factors, including regional demand, availability of raw materials, and technological advancements. In North America, for instance, the construction sector has been a significant driver of innovation in composite materials. The growing trend toward sustainable building practices has prompted manufacturers to invest in research and development to create high-performance panels that meet stringent environmental standards. Consequently, the region has seen a rise in production capacity, with several companies focusing on creating eco-friendly composites that cater to both residential and commercial projects.

In Europe, the focus on sustainability is similarly strong, with many countries implementing policies that encourage the use of renewable materials in construction. The European Union’s commitment to reducing greenhouse gas emissions and promoting energy-efficient buildings has spurred investments in advanced manufacturing technologies. As a result, European manufacturers are increasingly producing plastic composite panels that not only meet aesthetic and functional demands but also adhere to rigorous environmental regulations. The emphasis on innovation in this region has led to the development of lightweight, high-strength panels that are suitable for a variety of applications, including facades, roofing, and interior design.

In Asia, the landscape for plastic composite panel production is rapidly evolving. Countries such as China and India are emerging as key players in the global market, driven by urbanization and infrastructure development. The demand for modern building materials in these regions is growing, particularly as cities expand and the need for sustainable solutions becomes more pressing. Asian manufacturers are leveraging advanced production techniques and investing in technology to enhance the performance characteristics of plastic composite panels. These developments are crucial for meeting the unique challenges posed by diverse climates and varying building regulations across the continent.

Global production capacity distribution is also being shaped by the increasing collaboration between manufacturers and research institutions. Partnerships focused on innovation are leading to the development of new formulations and composite materials that offer improved properties, such as enhanced fire resistance, increased tensile strength, and better thermal insulation. Such advancements not only improve the performance of plastic composite panels but also expand their applicability across different sectors, including automotive, aerospace, and consumer goods.

Furthermore, the rise of digital manufacturing technologies, such as 3D printing and automated fabrication, is revolutionizing the way plastic composite panels are produced. These technologies allow for greater customization and flexibility in design while reducing waste and production time. As manufacturers adopt these innovative approaches, the efficiency of production processes improves, leading to a more sustainable model that aligns with the principles of eco-friendly construction.

The global market for plastic composite panels is witnessing a surge in demand, driven by a growing awareness of environmental issues and the need for sustainable building materials. As architects and builders increasingly prioritize eco-friendly solutions, the production capacity for these innovative panels is expected to expand further. This growth will be accompanied by continuous advancements in material science and manufacturing technologies, ensuring that plastic composite panels remain at the forefront of modern construction practices.

In conclusion, the distribution of global production capacity for innovative plastic composite panels is reflective of a broader trend towards sustainability and efficiency in the construction industry. As regions around the world prioritize eco-friendly solutions, manufacturers are responding with advanced materials that meet the demands of modern building and design projects. The future of plastic composite panels looks promising, with ongoing innovations poised to enhance their performance and expand their application across various sectors. As we move towards a more sustainable future, these materials will play a crucial role in shaping the next generation of environmentally conscious architecture and design.