Full Form of WPC Panel: Learn the Full Form of WPC Panel and Its Applications

Full Form of WPC Panel: Learn the Full Form of WPC Panel and Its Applications WPC stands for Wood Plastic Composite, a material that combines the properties of wood and plastic to create a versatile and durable product. WPC panels have gained significant popularity in recent years due to their unique characteristics, making them suitable…

Full Form of WPC Panel: Learn the Full Form of WPC Panel and Its Applications

WPC stands for Wood Plastic Composite, a material that combines the properties of wood and plastic to create a versatile and durable product. WPC panels have gained significant popularity in recent years due to their unique characteristics, making them suitable for a wide range of applications. This article will delve into the full form of WPC panels, their benefits, and various applications, while also highlighting their maintenance-free nature in the later stages of their lifecycle.

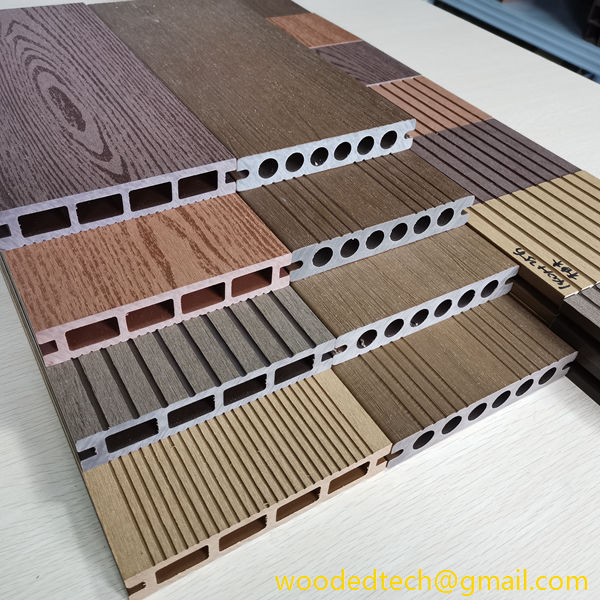

WPC panels are essentially manufactured from a blend of wood fibers and thermoplastics, such as polyethylene, polypropylene, or polyvinyl chloride (PVC). The combination of these materials results in a composite that possesses the aesthetic appeal of wood while offering the resilience and weather resistance of plastic. This innovative approach to material design has revolutionized the construction and design industries, providing a sustainable alternative to traditional materials.

One of the most significant advantages of WPC panels is their maintenance-free nature, particularly in the later stages of their use. Unlike traditional wood, which requires regular treatment with oils, stains, or sealants to maintain its appearance and prevent decay, WPC panels offer a much lower maintenance requirement. They are resistant to moisture, insects, and rot, making them an ideal choice for outdoor applications. This characteristic not only reduces the time and effort required for upkeep but also lowers the long-term costs associated with maintenance.

In addition to their low maintenance requirements, WPC panels are also environmentally friendly. The production process incorporates recycled wood and plastic materials, which helps reduce waste and conserves natural resources. This sustainable approach appeals to environmentally conscious consumers and industries, as it aligns with the growing trend toward eco-friendly building materials.

WPC panels have a wide range of applications across various sectors, including construction, furniture manufacturing, and interior design. In the construction industry, they are commonly used for decking, cladding, and fencing. The durability and weather resistance of WPC panels make them suitable for outdoor environments, where they can withstand the elements without warping or fading. Additionally, their aesthetic versatility allows designers to create visually appealing structures that mimic the look of traditional wood without the associated maintenance challenges.

In furniture manufacturing, WPC panels are used for tabletops, cabinets, and shelving. The material’s strength and resistance to moisture make it an excellent choice for kitchen and bathroom applications, where exposure to water is a concern. Furthermore, WPC panels can be easily shaped and finished, allowing manufacturers to create customized pieces that meet specific design requirements.

Interior design has also benefited from the use of WPC panels. They can be employed as wall paneling, decorative accents, or even in the creation of innovative partitions. The variety of colors, textures, and finishes available in WPC panels allows designers to achieve a wide range of aesthetics, from modern minimalist to rustic charm. This versatility makes WPC panels an attractive option for both residential and commercial spaces.

Another significant benefit of WPC panels is their ease of installation. They are typically lightweight and can be easily cut to size, making them a convenient choice for builders and DIY enthusiasts alike. The installation process is often quicker than that of traditional materials, which can lead to reduced labor costs and faster project completion times. This efficiency is particularly valuable in the fast-paced construction industry, where time is often of the essence.

WPC panels are also resistant to fading and discoloration, ensuring that their appearance remains consistent over time. This feature is especially important in outdoor applications, where exposure to sunlight can cause traditional wood to fade and lose its luster. With WPC panels, homeowners and builders can enjoy long-lasting beauty without the need for frequent refinishing or replacement.

Moreover, the adaptability of WPC panels allows for creative design solutions that can enhance functionality and aesthetics. For instance, they can be used to create innovative outdoor living spaces, such as patios and pergolas, that seamlessly blend with the natural environment. Their ability to replicate the look of wood while offering enhanced durability and low maintenance makes them a favored choice among architects and designers.

In summary, WPC panels, or Wood Plastic Composites, represent a significant advancement in material technology. Their full form encapsulates a blend of wood and plastic that offers a range of benefits, including low maintenance, durability, and environmental sustainability. With applications spanning construction, furniture manufacturing, and interior design, WPC panels have established themselves as a versatile and attractive option for a variety of projects. As the demand for maintenance-free materials continues to grow, WPC panels are likely to become an increasingly popular choice for consumers seeking both performance and aesthetics in their building materials. By embracing WPC technology, individuals and industries can contribute to a more sustainable future while enjoying the benefits of a modern, low-maintenance solution.