Explore the Benefits of Plastic Composite Wood for a Sustainable and Durable Building Material

Explore the Benefits of Plastic Composite Wood for a Sustainable and Durable Building Material In recent years, the construction industry has been undergoing significant changes as it seeks to adopt more sustainable practices. One of the standout materials gaining traction is plastic composite wood. This innovative building material is crafted from a blend of recycled…

Explore the Benefits of Plastic Composite Wood for a Sustainable and Durable Building Material

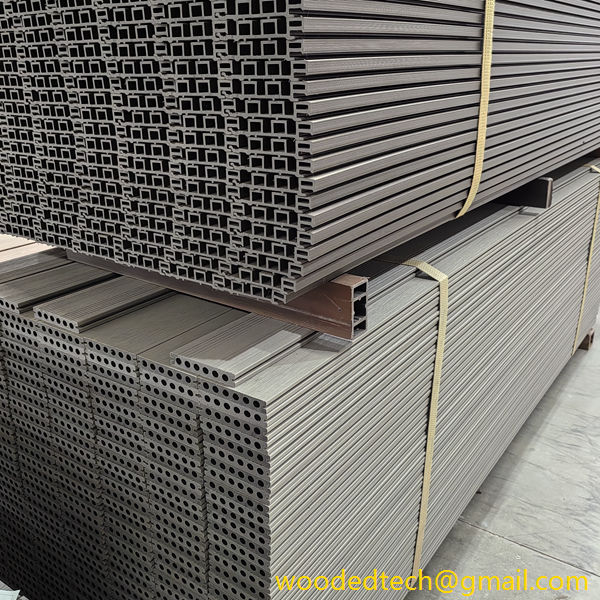

In recent years, the construction industry has been undergoing significant changes as it seeks to adopt more sustainable practices. One of the standout materials gaining traction is plastic composite wood. This innovative building material is crafted from a blend of recycled plastics and wood fibers, offering a plethora of advantages that make it an appealing choice for builders and architects alike. As the demand for sustainable materials continues to rise, the cost advantages associated with production areas in China further enhance the appeal of plastic composite wood.

Plastic composite wood is primarily made from recycled materials, which helps reduce waste and promotes a circular economy. By repurposing plastics that would otherwise end up in landfills or oceans, the production of composite wood not only minimizes environmental impact but also conserves natural resources. The use of wood fibers, often sourced from sustainably managed forests, adds another layer of sustainability to the material. This dual eco-friendly approach aligns well with global efforts to reduce carbon footprints and promote green building practices.

China has emerged as a leading producer of plastic composite wood due to its vast manufacturing capabilities and access to raw materials. The country has invested heavily in recycling technologies and infrastructure, allowing it to source large quantities of recycled plastics efficiently. This capacity not only helps meet the growing demand for sustainable materials but also positions China as a key player in the global market for composite wood products.

One of the most significant benefits of sourcing plastic composite wood from China is the cost advantage. The production cost in China is often lower than in many Western countries due to several factors. These include lower labor costs, economies of scale, and well-established supply chains. Chinese manufacturers can produce plastic composite wood at a fraction of the cost compared to their counterparts in regions with higher labor and production costs.

Moreover, China’s robust infrastructure facilitates efficient transportation and distribution, further reducing expenses associated with logistics. When combined with the country’s capacity to produce high-quality composite materials, these cost advantages make Chinese plastic composite wood an attractive option for builders and developers looking to adhere to budget constraints without sacrificing quality.

Plastic composite wood is renowned for its durability and low maintenance requirements. Unlike traditional wood, which is susceptible to rot, mold, and insect damage, composite wood is resistant to these common issues. This resilience translates into longer lifespans for structures built with composite materials, ultimately leading to lower lifecycle costs.

The durability of plastic composite wood is particularly advantageous in regions with harsh weather conditions. Whether exposed to intense sunlight, heavy rain, or fluctuating temperatures, composite wood maintains its integrity and aesthetic appeal over time. This reliability reduces the need for frequent repairs or replacements, offering significant cost savings in the long run.

Additionally, the low maintenance nature of plastic composite wood is a major selling point. Traditional wood requires regular sealing, staining, and other protective treatments to maintain its appearance and functionality. In contrast, composite wood can be easily cleaned with soap and water, allowing property owners to save on maintenance costs and labor.

Another notable benefit of plastic composite wood is its aesthetic versatility. Available in a wide range of colors, textures, and finishes, composite wood can mimic the appearance of natural wood while providing the added benefits of durability and low maintenance. This aesthetic appeal makes it an excellent choice for various applications, including decking, fencing, siding, and outdoor furniture.

The ability to customize the look of plastic composite wood allows architects and designers to create visually striking structures without compromising on sustainability. As more consumers prioritize eco-friendly options, the demand for aesthetically pleasing materials that also contribute to sustainable building practices continues to grow.

In an era where environmental consciousness is paramount, the use of plastic composite wood supports compliance with increasingly stringent building codes and regulations focused on sustainability. Many regions are implementing guidelines that encourage the use of recycled materials in construction. By choosing plastic composite wood, builders can demonstrate their commitment to sustainable practices while ensuring adherence to these regulations.

Furthermore, the adoption of plastic composite wood contributes to the overall reduction of greenhouse gas emissions. By utilizing recycled materials, the need for virgin plastic production is diminished, leading to lower energy consumption and reduced carbon emissions. This aligns with global sustainability goals and positions companies as responsible stewards of the environment.

The benefits of plastic composite wood as a sustainable and durable building material are numerous. Its eco-friendly production process, cost advantages associated with Chinese manufacturing, durability, low maintenance requirements, aesthetic versatility, and support for regulatory compliance make it an increasingly popular choice in the construction industry. As the world continues to prioritize sustainability in building practices, plastic composite wood stands out as a compelling option that meets the needs of both builders and environmentally conscious consumers. The combination of these factors ensures that plastic composite wood will remain a key player in the construction landscape for years to come, paving the way for a more sustainable future.