Análisis de los factores de coste de los suelos de WPC para realizar mejoras en el hogar sin salirse del presupuesto

Los suelos de compuesto de madera y plástico (WPC) han ganado gran popularidad en los últimos años como opción viable para los propietarios de viviendas que buscan un equilibrio entre atractivo estético y practicidad. El WPC combina la elegancia natural de la madera con la durabilidad del plástico, lo que lo convierte en una opción atractiva para diversos proyectos de mejora del hogar. Sin embargo, al considerar los suelos de WPC, hay que...

Wood Plastic Composite (WPC) flooring has gained significant popularity in recent years as a viable option for homeowners seeking a balance between aesthetic appeal and practicality. WPC combines the natural elegance of wood with the durability of plastic, making it an attractive choice for various home improvement projects. However, when considering WPC flooring, understanding the cost factors involved in its production and installation is crucial for homeowners who want to stay within budget. This article outlines the key elements influencing the cost of WPC flooring from a materials production process perspective.

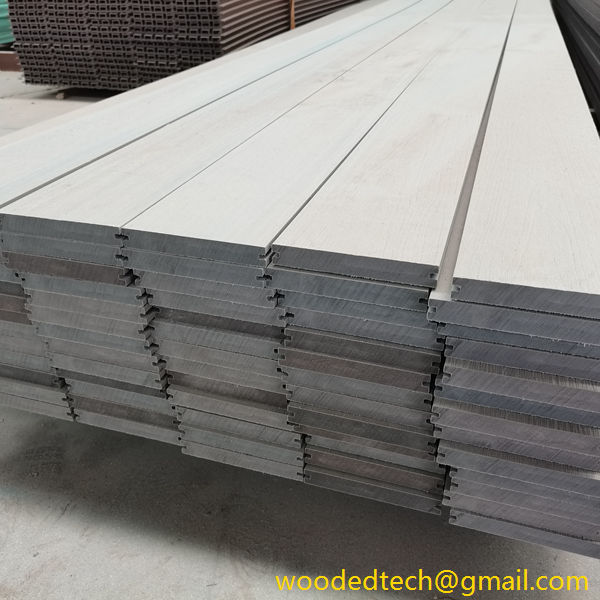

The first factor to consider is the raw materials used in WPC flooring production. Typically, WPC consists of a mixture of wood fibers, plastic polymers, and various additives. The quality and source of these materials can significantly impact the overall cost. Higher quality wood fibers and advanced plastic formulations enhance the flooring’s durability and appearance but may also increase the price. Conversely, opting for lower-grade materials may reduce costs but could compromise performance and longevity. Homeowners should weigh the long-term benefits of investing in higher-quality materials against the upfront savings of cheaper alternatives.

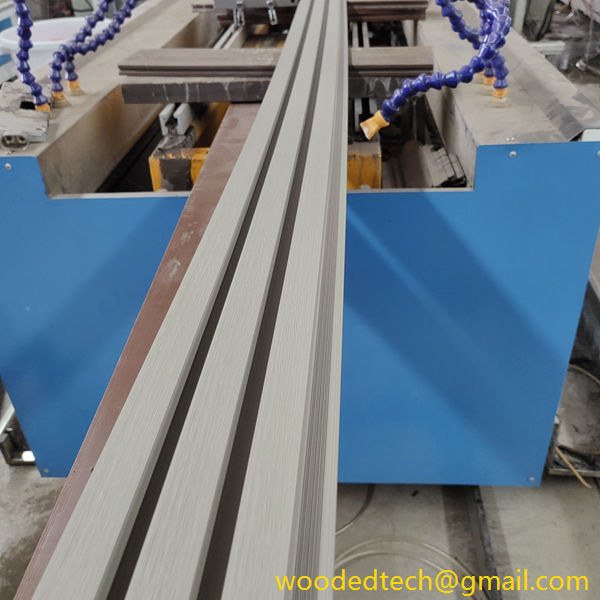

Another critical aspect of the production process is the manufacturing technology employed. The method used to combine wood and plastic can vary, leading to differences in quality and cost. Extrusion is a common technique where the materials are heated and forced through a die to create planks. While this method is efficient and cost-effective for mass production, it may not always yield the highest quality products. In contrast, more advanced techniques like injection molding can produce superior flooring options but at a higher cost. Homeowners should consider the manufacturing method when evaluating WPC flooring options, as it directly affects both price and performance.

The design and texture of WPC flooring also play a significant role in its cost. Flooring options with intricate designs, embossed textures, or realistic wood grain finishes typically require more sophisticated manufacturing processes, which can increase the price. While these features can enhance the aesthetic appeal of the flooring, homeowners should assess whether these design elements justify the additional cost. In some cases, simpler designs may offer a more budget-friendly solution without sacrificing too much in terms of appearance.

Installation costs are another crucial factor to consider when analyzing the overall expense of WPC flooring. While WPC is generally easier to install compared to traditional hardwood flooring, factors such as the complexity of the installation area, the need for underlayment, and local labor rates can influence the total cost. Homeowners who choose to hire professional installers should obtain multiple quotes to ensure they receive a fair price. Alternatively, for those with DIY skills, installing WPC flooring themselves can lead to substantial savings.

Additionally, the market dynamics and regional availability of WPC flooring can also affect pricing. In areas where WPC flooring is highly sought after, prices may be elevated due to demand. Conversely, in regions where alternative flooring options dominate, WPC may be more competitively priced. Homeowners should consider shopping around and comparing prices from different suppliers to find the best deals.

Finally, warranty and after-sales support should not be overlooked when evaluating WPC flooring costs. Many manufacturers offer warranties that cover defects and premature wear, which can provide peace of mind to homeowners making a significant investment. A longer warranty period may indicate higher quality materials and production standards, which could justify a higher price point. Additionally, good after-sales support can save homeowners time and money in case they encounter issues with their flooring.

In conclusion, while WPC flooring presents an appealing option for budget-friendly home improvements, it is essential to consider the various cost factors associated with its production and installation. By evaluating the quality of raw materials, manufacturing methods, design features, installation costs, market dynamics, and warranty options, homeowners can make informed decisions that align with their budgetary constraints and long-term goals. Ultimately, investing time in research and planning can lead to a successful and satisfying home improvement project that enhances both the functionality and aesthetic value of a home.