Durable and Attractive Plastic Wood Effect Exterior Cladding for a Low-Maintenance Building Exterior

Durable and Attractive Plastic Wood Effect Exterior Cladding for a Low-Maintenance Building Exterior In recent years, the construction industry has seen a significant shift toward sustainable and low-maintenance materials. One of the standout options that has gained popularity is plastic wood effect exterior cladding. This innovative material not only mimics the appearance of natural wood…

Durable and Attractive Plastic Wood Effect Exterior Cladding for a Low-Maintenance Building Exterior

In recent years, the construction industry has seen a significant shift toward sustainable and low-maintenance materials. One of the standout options that has gained popularity is plastic wood effect exterior cladding. This innovative material not only mimics the appearance of natural wood but also offers a range of advantages that make it an attractive choice for builders and homeowners alike. Among these advantages, the cost-effectiveness of production in China plays a pivotal role in making this cladding an appealing option for various construction projects.

China has established itself as a global leader in manufacturing, and its production capabilities have a profound impact on the cost of building materials, including plastic wood effect exterior cladding. This cost advantage can be attributed to several key factors.

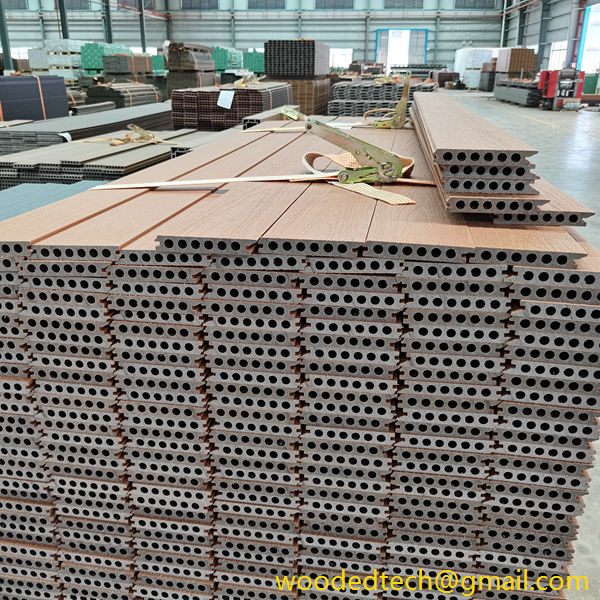

Firstly, the scale of production in China allows for economies of scale. Large manufacturing facilities can produce materials in bulk, which reduces the cost per unit. This is particularly beneficial for plastic wood effect cladding, which requires significant raw materials. With efficient production processes and advanced machinery, Chinese manufacturers can produce high-quality cladding at a fraction of the cost compared to other regions. This not only lowers the purchase price for consumers but also enables builders to offer competitive pricing in their projects.

Secondly, China has a well-established supply chain for the raw materials needed to produce plastic wood effect cladding. The availability of locally sourced materials, combined with a vast network of suppliers, minimizes transportation costs and leads to more efficient production cycles. This streamlined supply chain further enhances the cost advantages of sourcing cladding from China.

Additionally, labor costs in China are generally lower than in many Western countries. While this has been a point of contention in global trade, it undeniably contributes to the overall affordability of products manufactured in the country. The lower labor costs allow manufacturers to keep prices competitive without compromising on quality. Consequently, builders and homeowners can access durable and aesthetically pleasing cladding options without exceeding their budgets.

Beyond cost advantages, another crucial factor driving the popularity of plastic wood effect exterior cladding is its sustainability. As the construction industry increasingly prioritizes environmentally friendly materials, the production of plastic wood effect cladding aligns well with these goals. Many manufacturers in China are now utilizing recycled materials in their production processes, contributing to reduced waste and a lower carbon footprint.

This sustainable approach resonates with consumers who are more conscious of their environmental impact. By choosing plastic wood effect cladding, builders and homeowners can not only achieve a beautiful aesthetic that mimics natural wood but also support eco-friendly practices. This aspect of the product can be a significant selling point, particularly in markets where sustainability is a key concern.

Durability is another standout feature of plastic wood effect exterior cladding that enhances its attractiveness. Unlike traditional wood, which can be susceptible to rot, warping, and insect damage, plastic wood effect cladding is designed to withstand the elements. This means that homeowners and builders can enjoy a long-lasting exterior that requires minimal maintenance over time.

The low-maintenance nature of plastic wood effect cladding is a significant advantage for both residential and commercial properties. With traditional wood cladding, regular maintenance such as painting, staining, and sealing is necessary to preserve its appearance and integrity. In contrast, plastic wood effect cladding typically requires only occasional cleaning to maintain its visual appeal. This not only saves time and effort but also reduces long-term costs associated with upkeep and repairs.

In addition to its practical benefits, plastic wood effect exterior cladding is also aesthetically pleasing. The material can closely replicate the look and feel of natural wood, allowing for a warm and inviting exterior that enhances the overall curb appeal of a building. Available in a variety of colors and finishes, plastic wood effect cladding offers versatility in design, making it suitable for various architectural styles.

Homeowners can choose from a range of textures and shades to create their desired look, whether they prefer the rustic charm of weathered wood or the sleek lines of contemporary design. This aesthetic flexibility allows builders to cater to diverse client preferences while maintaining the durability and low-maintenance benefits of the material.

As the demand for low-maintenance and sustainable building materials continues to rise, plastic wood effect exterior cladding stands out as a compelling option. The cost advantages offered by Chinese production, combined with the durability, low-maintenance requirements, and aesthetic appeal of the material, make it an attractive choice for builders and homeowners alike. With the construction industry increasingly embracing innovative solutions, plastic wood effect cladding is poised to play a significant role in shaping the future of building exteriors. By choosing this material, consumers not only benefit from cost savings but also contribute to sustainable building practices that align with modern environmental standards.