Choosing Plastic Wood for Decking to Create a Long-Lasting and Low-Maintenance Outdoor Space

Choosing Plastic Wood for Decking to Create a Long-Lasting and Low-Maintenance Outdoor Space When it comes to enhancing outdoor spaces, particularly through the construction of decks, the choice of material plays a pivotal role in determining both the aesthetic appeal and practical functionality of the area. Among the various options available, plastic wood, also commonly…

Choosing Plastic Wood for Decking to Create a Long-Lasting and Low-Maintenance Outdoor Space

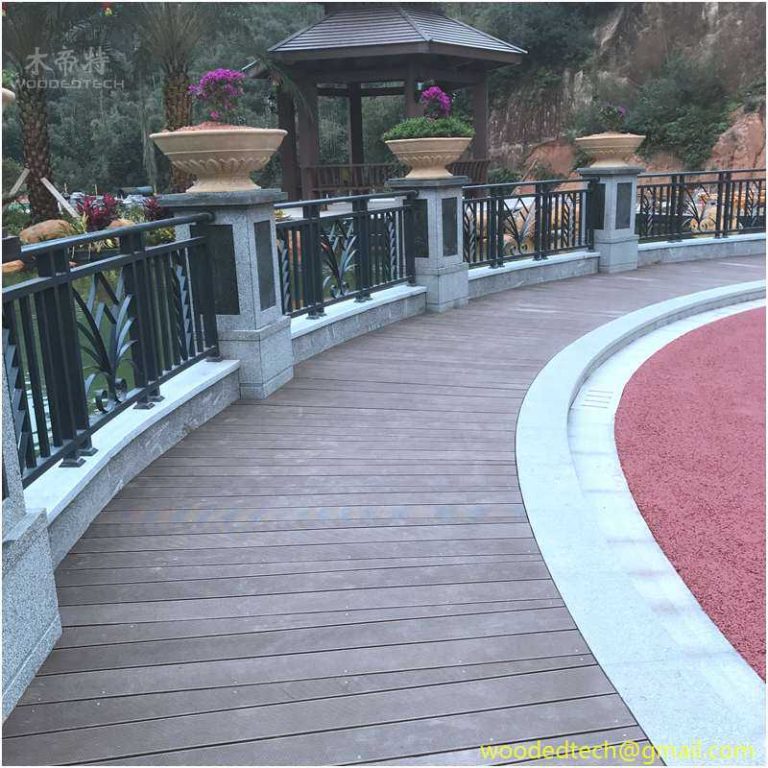

When it comes to enhancing outdoor spaces, particularly through the construction of decks, the choice of material plays a pivotal role in determining both the aesthetic appeal and practical functionality of the area. Among the various options available, plastic wood, also commonly referred to as composite decking, has emerged as a popular choice for homeowners and builders alike. This article explores the benefits of choosing plastic wood for decking, focusing on its longevity, low maintenance requirements, and the technology behind its production.

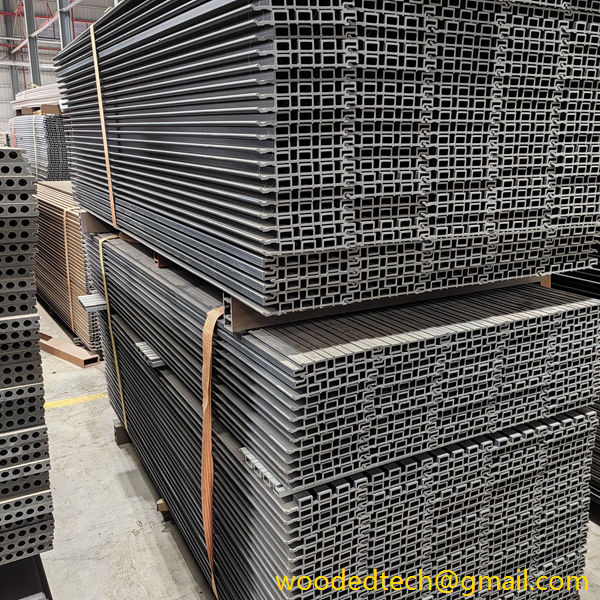

Plastic wood is primarily made from a blend of wood fibers and recycled plastic. This innovative composition not only mimics the appearance of traditional wood but also offers enhanced durability and resistance to the elements. The production technology behind plastic wood has evolved significantly over the years, allowing manufacturers to create products that meet the increasing demands for sustainability and performance in outdoor construction.

One of the primary advantages of plastic wood decking is its long-lasting nature. Traditional wood, while aesthetically pleasing, is often susceptible to deterioration from weather-related elements such as moisture, UV rays, and insect infestations. Over time, this can lead to warping, cracking, and splintering, necessitating frequent repairs or replacements. In contrast, plastic wood is engineered to withstand these harsh conditions. The combination of wood fibers and plastic creates a robust material that resists fading, staining, and corrosion, ensuring that the deck maintains its visual appeal and structural integrity for years to come.

Moreover, the longevity of plastic wood translates into cost savings for homeowners. While the initial investment may be higher than that of traditional wood, the reduced need for repairs and replacement over time makes plastic wood a more economical choice in the long run. Additionally, many manufacturers offer warranties that further assure consumers of the durability and quality of their products.

Another significant benefit of plastic wood decking is its low maintenance requirements. Traditional wood decks require regular upkeep, including sealing, staining, and painting, to preserve their appearance and protect against deterioration. This not only demands time and effort but also incurs ongoing costs. In contrast, plastic wood is designed to be virtually maintenance-free. It does not require sanding, staining, or sealing, allowing homeowners to enjoy their outdoor spaces without the burden of extensive upkeep. A simple soap-and-water wash is typically all that is needed to keep plastic wood looking fresh. This ease of maintenance is particularly appealing to busy individuals and families who wish to maximize their enjoyment of outdoor spaces rather than spend time on maintenance tasks.

From an environmental perspective, the production of plastic wood also aligns with growing sustainability concerns. By utilizing recycled materials, such as post-consumer plastics, plastic wood not only diverts waste from landfills but also reduces the demand for virgin materials. Many manufacturers are committed to sustainable practices, ensuring that their products are not only durable but also environmentally friendly. This makes plastic wood an attractive option for eco-conscious consumers who are looking to minimize their environmental footprint while enhancing their outdoor spaces.

The technology involved in the production of plastic wood has also advanced to enhance its performance. Innovations in manufacturing processes, such as co-extrusion, create a protective layer on the surface of the decking that enhances its resistance to fading, staining, and scratching. This means that plastic wood can maintain its color and finish over time, even in the face of harsh weather conditions. Furthermore, some products incorporate advanced technologies that improve slip resistance, making them safer for use around pools or in wet conditions.

Aesthetic versatility is another reason why plastic wood has gained popularity in decking applications. Available in a wide range of colors, textures, and finishes, plastic wood can be customized to suit various architectural styles and personal preferences. Whether one desires the rich tones of traditional hardwood or the sleek look of modern materials, plastic wood can provide the desired aesthetic without compromising on performance.

In summary, choosing plastic wood for decking is an excellent decision for those looking to create a long-lasting and low-maintenance outdoor space. Its durability ensures that it can withstand the rigors of weather and daily use, while the minimal maintenance requirements allow homeowners to enjoy their decks without the constant upkeep associated with traditional wood. Additionally, the sustainability of plastic wood production aligns with modern environmental concerns, making it a responsible choice for eco-conscious consumers. With advanced manufacturing technologies enhancing its performance and aesthetic appeal, plastic wood stands out as a premier option for outdoor decking solutions. As homeowners continue to invest in their outdoor spaces, plastic wood is poised to remain a leader in material production technology, offering both beauty and practicality.