wpc panel fire resistance

wpc panel fire resistance

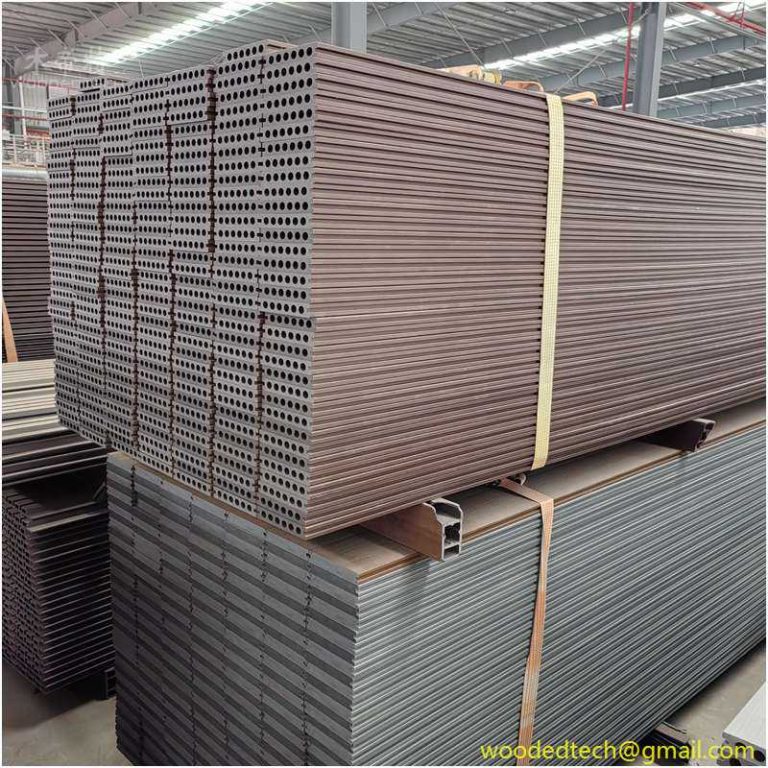

In today’s society, people’s demand for environmental protection and aesthetics is growing, which has prompted wpc panel to become a mainstream product in the template industry.

However, despite its wide acclaim for its environmental performance and appearance, the common wpc panel s on the market generally do not have fire resistance, which is an issue that cannot be ignored for consumers and companies pursuing higher safety standards. .

Let’s first analyze why the fire resistance of wpc panel is so important. .

In homes or public places, fire safety is always one of the top considerations.

Once a fire occurs, fireproof materials can effectively delay the spread of the fire and buy precious time for people to evacuate, thereby reducing potential loss of life and property.

Therefore, improving the fire resistance of wpc panel is not only responsible for the safety of consumers’ lives, but also a key factor in improving the market competitiveness of products. .

How to make wpc panel have a higher fire protection standard? In fact, through technological innovation and material improvement, it is entirely possible for wpc panel to reach the fire protection B1 level. .

This level means that the material can extinguish itself when encountering a flame, and there will be no dripping or spreading of flames.

For example, https://woodedtech.com/ is committed to the research and development and promotion of wood-plastic composite materials and their products. Through continuous technological innovation, it promotes the development of the domestic wood-plastic industry, including improving the fire resistance of products. .

As an industry pioneer, the company has participated in the drafting and compilation of many national and industry standards, demonstrating its determination and strength in improving the fire resistance of wpc panel s.

There are many technical paths to achieve the B1 fire resistance of wpc panel s. .

For example, specific fire retardants can be added to the raw materials, which can form a protective layer at high temperatures, isolate oxygen, and prevent further combustion of the material.

Or surface treatment technologies such as coating or coating with special fire retardant materials can be used to enhance the fire resistance of the floor.

It is worth mentioning that these technical improvements will not only not affect the environmental protection characteristics and aesthetics of the wpc panel itself, but also add additional functionality, such as better wear resistance and pollution resistance. .

Although the common wpc panel s on the market may not have fire resistance, through technological innovation and industrial upgrading, wpc panel s can fully reach the fire protection level B1, which not only meets the market’s demand for safety and environmental protection, but also provides the possibility for enterprises to open up a broader market space. .

With the continuous advancement of technology and the improvement of consumer safety awareness, we have reason to believe that in the future, wpc panel s will pay more attention to and improve their fire resistance while ensuring beauty. .