Easy Installation of Wood Plastic Composite Flooring: A Step-by-Step Guide

Easy Installation of Wood Plastic Composite Flooring: A Step-by-Step Guide Wood Plastic Composite (WPC) flooring has emerged as a popular choice for both residential and commercial spaces. It combines the aesthetic appeal of natural wood with the durability and low maintenance of synthetic materials, making it an ideal flooring option for various environments. As the…

Easy Installation of Wood Plastic Composite Flooring: A Step-by-Step Guide

Wood Plastic Composite (WPC) flooring has emerged as a popular choice for both residential and commercial spaces. It combines the aesthetic appeal of natural wood with the durability and low maintenance of synthetic materials, making it an ideal flooring option for various environments. As the demand for WPC flooring continues to grow, understanding the installation process is essential for homeowners and contractors alike. This article provides a comprehensive step-by-step guide to installing WPC flooring, while also considering the global production capacity distribution of this innovative material.

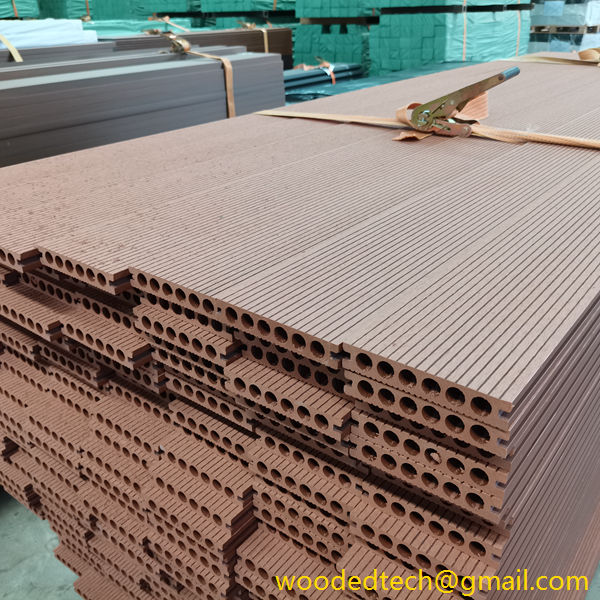

Before delving into the installation process, it is important to understand what WPC flooring is. WPC is made from a blend of wood fibers and plastic, which are combined to create a product that is both strong and lightweight. This unique composition gives WPC flooring its resistance to moisture, mold, and termites, making it suitable for areas prone to humidity, such as kitchens and bathrooms.

Moreover, WPC flooring is available in a variety of styles, colors, and textures, allowing homeowners to achieve the desired aesthetic without sacrificing functionality. Given its benefits, the production and installation of WPC flooring are becoming increasingly significant in the global flooring market.

The production of WPC flooring is distributed across various regions worldwide, influenced by factors such as availability of raw materials, technological advancements, and market demand. Countries with abundant timber resources, such as the United States, Canada, and several European nations, have become key players in the WPC flooring market. Meanwhile, countries in Asia, particularly China and India, have ramped up production to meet local and international demand.

The global distribution of production capacity also reflects the increasing focus on sustainability and eco-friendliness. Many manufacturers are adopting responsible sourcing practices, ensuring that the wood fibers used in WPC are derived from sustainably managed forests. This trend aligns with the growing consumer demand for environmentally friendly building materials.

1. Preparation: Before installation begins, it is crucial to prepare the subfloor. Ensure that the surface is clean, dry, and level. Any imperfections in the subfloor can lead to issues later, such as uneven flooring or gaps. If necessary, use a leveling compound to smooth out any uneven areas.

2. Acclimation: Allow the WPC planks to acclimate to the room’s temperature and humidity for at least 48 hours prior to installation. This step helps prevent expansion or contraction of the material once it is inst

3. Gather Tools and Materials**: Assemble all necessary tools for the installation process. Common tools include a tape measure, saw, spacers, rubber mallet, and tapping block. Additionally, ensure you have the right underlayment if required by the manufacturer.

4. Plan the Layout: Before laying the planks, plan the layout of the flooring. Start by determining the direction in which the planks will be installed. Typically, flooring is laid parallel to the longest wall in the room. Use chalk lines to guide your installation and ensure a straight layout.

5. Install the First Row: Begin by placing the first row of WPC planks along the chalk line. Use spacers to maintain a gap of approximately 1/4 inch from the walls. This gap allows for natural expansion and contraction of the material. Ensure that the planks are tightly fitted together using the tongue-and-groove mechanism.

6. Continue Installing Rows: Proceed to install subsequent rows of planks, staggering the seams for a more natural appearance. This staggered pattern not only enhances the aesthetics but also provides structural stability to the flooring. Use a rubber mallet and tapping block to ensure a snug fit between planks.

7. Cutting Planks: When you reach the end of a row or encounter obstacles such as doorways or vents, you may need to cut the planks to fit. Use a saw to make precise cuts, ensuring that the ends of the planks are straight and clean.

8. Final Touches: Once all the planks are installed, remove the spacers and install baseboards or trims to cover the expansion gaps along the walls. This gives the flooring a finished look and helps secure the edges of the planks.

9. Cleaning and Maintenance: After installation, clean the flooring with a damp mop or cloth to remove any dust or debris. WPC flooring is relatively low maintenance, but regular cleaning and occasional maintenance can help preserve its appearance.

Wood Plastic Composite flooring offers an attractive, durable, and environmentally friendly alternative to traditional flooring materials. The global production capacity for WPC is expanding as consumers increasingly seek sustainable options for their homes and businesses. By following this step-by-step guide, individuals can successfully install WPC flooring and enjoy its numerous benefits. As the market continues to evolve, staying informed about installation best practices and production trends will be essential for both consumers and industry professionals.