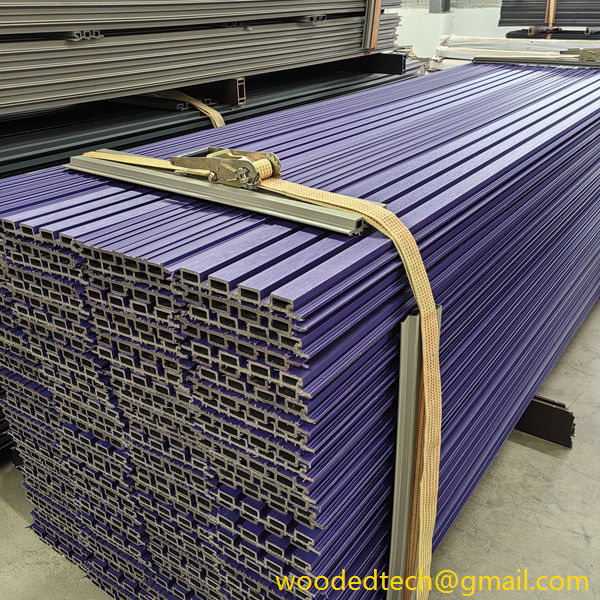

wpc flooring texture

Whether it is polishing, brushing or embossing, each surface treatment method has its applicable scenarios and advantages.

Understanding the characteristics and applications of these treatments can help us make more appropriate choices when purchasing and using wpc flooring.

As a new type of environmentally friendly material, wpc flooring has been very popular in the market in recent years. It not only has the texture and beauty of wood, but also has the durability and waterproofness of plastic.

However, you may not know that a seemingly ordinary wpc flooring has a lot of knowledge before it leaves the factory.

Today, let’s talk about the surface treatment methods of wpc flooring, which include grinding, brushing and embossing. Each treatment method gives the floor a unique style and practical characteristics.

Speaking of grinding, this is a common surface treatment method.

By grinding, the burrs and unevenness on the surface of the wpc flooring can be removed, making it smoother.

This method is suitable for occasions where a smooth surface is required.

The polished wpc flooring feels more delicate, comfortable to the feet, and easy to clean and maintain.

Next is brushing, which will form a fine linear texture on the surface of the floor.

The brushed wpc flooring not only has a more unique appearance, but also increases the anti-slip performance of the floor.

This effect is particularly suitable for outdoor or humid environments, such as around swimming pools.

Let’s look at the embossing technology. This technology can press various patterns on the surface of wpc flooring, such as wood grain, stone grain, etc., which not only increases the aesthetics, but also enhances the anti-slip property of the floor, especially suitable for use in public areas or commercial places.

In the actual operation process, some problems may be encountered.

For example, if the polishing is not done properly, scratches may appear on the surface of the floor; if the brushing treatment is not well controlled, the overall flatness of the floor may be affected; and if the embossing technology is used improperly, the pattern may not be clear or uniform.

In the face of these problems, how should we solve them?

In fact, the key lies in mastering the correct treatment methods and techniques.

For polishing, sandpaper of appropriate particle size should be selected and the polishing should be kept uniform; when brushing, the pressure and speed of the machine need to be adjusted to ensure the uniform distribution of the texture; as for embossing, it is important to control the temperature and pressure to ensure that the pattern can be clearly displayed on the floor.

Whether it is polishing, brushing or embossing, each surface treatment method has its applicable scenarios and advantages.

Understanding the characteristics and applications of these treatments can help us make more appropriate choices when purchasing and using wpc flooring.

At the same time, mastering the correct treatment technology can also ensure the durability and practicality of the floor while enjoying the natural beauty.