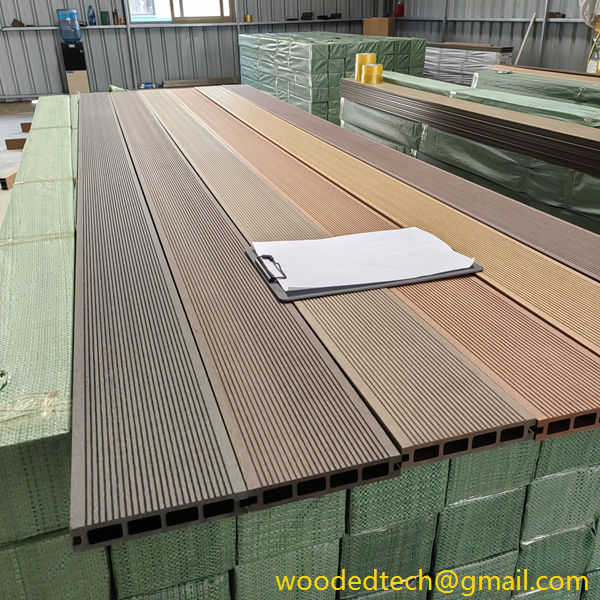

wpc decking technical data sheet

There are many technical indicators for wpc decking, and there are also many corresponding wpc decking standards. We have sorted out these indicators and previous test data, as shown in the attached table below.

wpc decking technical data sheet

China is the largest producer of wpc decking in the world. We are a well-known manufacturer of wpc decking in China. Our products meet various certifications, have excellent quality control, and are exported to the world.

There are many technical indicators for wpc decking, and there are also many corresponding wpc decking standards. We have sorted out these indicators and previous test data, as shown in the attached table below.

Technical Data Sheet

| WPC materials Performance Data Sheet | |||||||

| Num | Item | Standard | Product Scope | Result | Remarks | Application | |

| 1 | REACH | (EC) NO. 1907/2006 | All WPC | Pass | Test Harmful Contents | Hazardous Substance | |

| 2 | Pedestal Vertical Load Test | EN 12825:2001 | Pedestal | Pedestal Loading Test | Mechanical Test | ||

| 3 | Fire Performance | EN 13501 | All WPC | Bf1-S1 | For Fire-proof products | Fire-Proofing Test | |

| 4 | Fire Performance | ASTM E84 | All WPC | Class A – Top Level | For Fire-proof products | Fire-Proofing Test | |

| 5 | Pendulum Test | EN15534-1:2014 and CEN/TS | Suprotect | Pass | Slip Resistance Test | Safety Performance | |

| 6 | Moisture Resistance- Boiling Test | EN15534-1:2014 | Suprotect | Pass | Durability | ||

| 7 | Abrasion Resistance | ASTM D4060-14 | Suprotect | 37.9mg/1000r | Durability | ||

| 8 | Resistance to Artificial Weathering | EN15534-1:2014 | Suprotect | 4.5 Grade of colorfastness | 2000h | Durability | |

| 9 | Wind Resistance Test | / | Fence | Pass-No failiure or disengagement | 9-Scale Wind Load | Safety Performance | |

| 10 | Moisture Content | EN322.1993 | All WPC | 0.89% | Durability – Waterproof | ||

| 11 | Falling Mass Impact Resistance | EN15534-1:2014 | Normal WPC | 9mm | Residual Indentation | Mechanical Test | |

| 12 | Bending Strength | EN15534-1:2014 | All WPC | 26.8MPa | Mechanical Test | ||

| 13 | Modulus of Elasticity | EN15534-1:2014 | All WPC | 3758MPa | Mechanical Test | ||

| 14 | Withdrwal Capacity of Fastners | EN13446:2002 | All WPC | 4139N | Screw Surface Withdrawal Test | Mechanical Test | |

| 15 | Withdrwal Capacity of Fastners | EN13446:2002 | All WPC | 3370N | Screw Edge Withdrawal Test | Mechanical Test | |

| 16 | Coefficient of Linear Thermal Expansion | ISO 11359-2:1999 | All WPC | 66.75μm/m·℃ | Material Performance | ||

| 17 | Deflection Temperature under Load | ISO 75:2013 & ISO 75-2:2013 | All WPC | 80℃ | Durability | ||

| 18 | Oxygen Index | ASTM D2863-13 | Normal WPC | 21.80% | Fire-Resistance | Fire-Proofing Test | |

| 19 | Anti-Slip Property | DIN 51130-2014 | Suprotect | R10 | Safety Performance | ||

| 20 | Falling Mass Impact Resistance | EN15534-1:2014 | Suprotect | 0.16mm | Testing the Depth of Residual Indentation | Mechanical Test | |

| 21 | Resistance to Indentation | EN15534-1:2014 | Suprotect | Brinell Hardness: 65N/mm2 Rate of Elestic Recovery:77.7% | Durability | ||

| 22 | Rockwell Hardness | ASTM D785-08 | Suprotect | 83.3R | Surface Hardness | Durability | |

| 23 | Coefficient of Linear Thermal Expansion | EN15534-1:2014 | Hyper Wood | 38.6 | Material Performance | ||

| 24 | Bending Strength | EN15534-1:2014 | Hyper Wood | 46MPa | Mechanical Test | ||

| 25 | Modulus of Elasticity | EN15534-1:2014 | Hyper Wood | 4300MPa | Mechanical Test | ||

| 26 | Flexural Breaking Load | GB/T 24508-2009 | All WPC | 4091N | Pass | Mechanical Test | |

| 27 | Falling Mass Impact Resistance | GB/T 24508-2009 | All WPC | 6-7mm | Pass | Mechanical Test | |

| 28 | Density | GB/T 24508-2009 | All WPC | 1.22 | Pass | Material Performance | |

| 29 | Water Absorption Rate | GB/T 24508-2009 | All WPC | 0.90% | Pass | Material Performance | |

| 30 | Falling Ball Impact Test at Low | GB/T 24508-2009 | All WPC | -10℃ No Crack | Pass | Mechanical Test | |

| 31 | Dimension Changing Ratio of Swelling after Immersion in Water | GB/T 24508-2009 | All WPC | <0.1 | Pass | Material Performance | |

| 32 | Dimension Changing Ratio ager Heated | GB/T 24508-2009 | All WPC | 0.20% | Pass | Material Performance | |

| 33 | Thermal-Cold Cycliing Resistance | GB/T 24508-2009 | All WPC | No Cracking, No Bubble,0.2 | Pass | Durability | |

| 34 | Stain Resistance of Surface | GB/T 24508-2009 | All WPC | No Significant Change | Pass | Durability | |

| 35 | Free-Thaw Resistance | GB/T 24508-2009 | All WPC | 94% | Pass | Durability | |

| 36 | Creep Recovery Ratio | GB/T 24508-2009 | All WPC | 83% | Pass | Mechanical Test | |

| 37 | Slip Resistance | GB/T 24508-2009 | All WPC | 45 | Pass | Safety Performance | |

| 38 | Formaldehyde Emission | GB/T 24508-2009 | All WPC | E0-lowest level | Pass | Safety Performance | |

| 39 | Dissoluble Lead | GB/T 24508-2009 | All WPC | <0.5 | Pass | Safety Performance | |

| 40 | Dissoluble Cadmium | GB/T 24508-2009 | All WPC | <0.5 | Pass | Safety Performance | |