What is WPC Wall Cladding: Understanding the Basics of WPC Wall Cladding

What is WPC Wall Cladding: Understanding the Basics of WPC Wall Cladding WPC wall cladding, or Wood Plastic Composite wall cladding, is a modern construction material that has gained significant popularity in recent years. This innovative product combines the best features of wood and plastic, resulting in a versatile and durable solution for both interior…

What is WPC Wall Cladding: Understanding the Basics of WPC Wall Cladding

WPC wall cladding, or Wood Plastic Composite wall cladding, is a modern construction material that has gained significant popularity in recent years. This innovative product combines the best features of wood and plastic, resulting in a versatile and durable solution for both interior and exterior applications. Understanding the basics of WPC wall cladding involves exploring its composition, advantages, manufacturing processes, and applications in the construction industry.

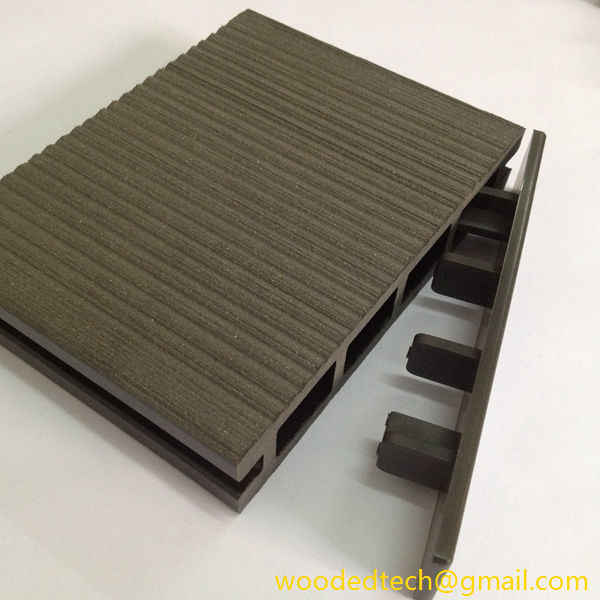

At its core, WPC is composed of two primary materials: wood fibers and thermoplastics. The wood fibers are typically sourced from recycled wood products, such as sawdust or wood shavings, making WPC an environmentally friendly option. The thermoplastics used in the production of WPC can vary, but common types include polyethylene, polypropylene, and polyvinyl chloride (PVC). The blending of these materials creates a composite that retains the aesthetic appeal of natural wood while benefiting from the durability and low maintenance properties of plastic.

One of the key advantages of WPC wall cladding is its resistance to various environmental factors. Unlike traditional wood, which is susceptible to decay, rot, and insect infestations, WPC is engineered to withstand harsh weather conditions. This makes it an ideal choice for outdoor applications, such as on the facades of buildings, decks, and fences. Additionally, WPC is resistant to moisture, which helps prevent issues related to mold and mildew that can commonly affect wooden structures.

WPC wall cladding also offers a significant advantage in terms of maintenance. Traditional wood cladding requires regular painting, staining, and sealing to preserve its appearance and structural integrity. In contrast, WPC wall cladding requires minimal maintenance. It can be simply cleaned with soap and water, and it does not require the same level of upkeep as natural wood. This attribute makes WPC particularly appealing to homeowners and builders looking for a long-lasting solution that saves time and effort.

The aesthetic versatility of WPC wall cladding is another notable feature. Manufacturers offer a wide range of colors, textures, and finishes, allowing for creative design possibilities. Whether a project calls for a modern, sleek appearance or a more rustic, traditional look, WPC can be customized to meet the specific aesthetic preferences of designers and homeowners. This flexibility in design makes WPC wall cladding a popular choice in both residential and commercial construction projects.

The manufacturing process of WPC involves several key steps. Initially, the wood fibers are combined with thermoplastic materials in a specific proportion, typically ranging from 30 to 60 percent wood fibers. This mixture is then heated and extruded to form boards or panels. The extrusion process allows for the creation of various profiles, such as tongue-and-groove joints, which can facilitate easier installation. After the extrusion, the panels may be cooled and cut to the desired lengths, ready for distribution.

In addition to its practical benefits, WPC wall cladding is also recognized for its sustainability. The use of recycled wood materials and the potential for recycling the composite product at the end of its life cycle contribute to a reduced environmental footprint. As the construction industry increasingly emphasizes sustainable practices, WPC wall cladding presents a compelling option for environmentally conscious builders and consumers.

Moreover, WPC wall cladding provides excellent thermal insulation properties, which can contribute to energy efficiency in buildings. By installing WPC cladding on exterior walls, property owners can improve the thermal performance of their structures, potentially reducing heating and cooling costs. This energy efficiency aligns with the growing trend toward sustainable building practices and green construction.

The application of WPC wall cladding extends beyond just exterior facades. It can also be used in interior spaces, such as feature walls, accent panels, and ceiling applications. The ability to create cohesive design elements with WPC allows architects and interior designers to achieve a unified aesthetic throughout a space. Additionally, WPC’s lightweight nature simplifies the installation process, making it an attractive option for various construction scenarios.

As the demand for innovative building materials continues to rise, WPC wall cladding stands out as a versatile and sustainable option that meets the needs of modern construction. Its unique combination of wood and plastic properties provides an effective solution for both aesthetic and functional requirements. With advances in manufacturing technology and an increasing focus on sustainability, WPC wall cladding is poised to play a significant role in shaping the future of construction materials.

In conclusion, WPC wall cladding represents a significant advancement in material production technology. By understanding its composition, advantages, and applications, builders and consumers can make informed decisions about incorporating this innovative product into their projects. Whether used for exterior facades or interior design elements, WPC wall cladding offers a durable, low-maintenance, and aesthetically pleasing solution that aligns with contemporary building practices and environmental considerations. As awareness of WPC continues to grow, its usage is expected to expand further, solidifying its place in the construction industry.