Installation WPC Cladding: Best Practices for Success

Installation WPC Cladding: Best Practices for Success Wood Plastic Composite (WPC) cladding has gained popularity in the construction and renovation sectors due to its unique blend of aesthetics, durability, and sustainability. As the demand for WPC cladding continues to rise, understanding the best practices for installation becomes crucial for achieving optimal results. This article delves…

Installation WPC Cladding: Best Practices for Success

Wood Plastic Composite (WPC) cladding has gained popularity in the construction and renovation sectors due to its unique blend of aesthetics, durability, and sustainability. As the demand for WPC cladding continues to rise, understanding the best practices for installation becomes crucial for achieving optimal results. This article delves into the essential guidelines for successfully installing WPC cladding, ensuring a long-lasting and visually appealing finish.

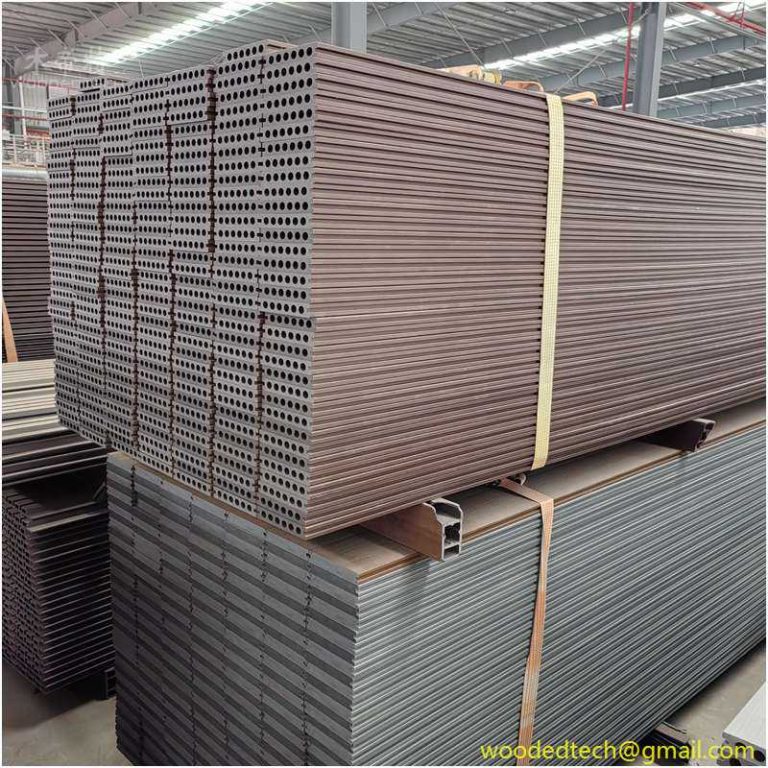

WPC cladding is composed of a mixture of wood fibers and plastic materials, which results in a product that mimics the appearance of natural wood while offering enhanced durability and resistance to environmental factors. This composite material is not only resistant to rot and decay but also requires minimal maintenance compared to traditional wood cladding. Additionally, WPC cladding is available in a variety of colors, textures, and finishes, making it a versatile choice for different architectural styles.

Before embarking on the installation process, it is essential to prepare adequately. This includes assessing the building structure and ensuring that the substrate is suitable for WPC cladding. The surface should be clean, dry, and free of any debris that might impede the installation. Proper ventilation must also be considered, as it helps in preventing moisture accumulation behind the cladding, which can lead to mold and mildew growth.

It is advisable to familiarize yourself with the manufacturer’s installation guidelines, as these can vary between different brands and products. Each WPC cladding system may have specific requirements concerning spacing, fasteners, and installation techniques. Adhering to these guidelines will help ensure a successful installation and maximize the longevity of the cladding.

Selecting the appropriate tools and materials is crucial for a smooth installation process. Basic tools required for installing WPC cladding include a measuring tape, level, saw, drill, and fasteners. When choosing fasteners, it is important to opt for stainless steel or coated screws that are corrosion-resistant, as this will prevent rusting and prolong the lifespan of the cladding.

In addition to fasteners, it is essential to use appropriate spacing clips or brackets, which allow for proper expansion and contraction of the material. WPC cladding can expand and contract with temperature changes, so ensuring adequate spacing between boards is necessary to avoid warping or buckling.

When it comes to installing WPC cladding, following systematic techniques will yield the best results. Start by laying the first board at the bottom of the wall, ensuring that it is level and securely fastened to the substrate. It is advisable to use a spacer to maintain consistent gaps between the boards, allowing for adequate ventilation and drainage.

As you progress with the installation, stagger the joints of the boards to enhance structural integrity and visual appeal. Staggering the joints helps to create a more natural appearance, mimicking the look of traditional wood cladding. Furthermore, it is essential to avoid using excessive force when fastening the boards, as this may lead to damage or distortion.

Pay attention to the end cuts of the boards, as they may require sealing to prevent moisture infiltration. Some manufacturers offer end caps or sealing products designed specifically for this purpose. Applying these seals can significantly enhance the cladding’s resistance to environmental factors.

Once installed, maintaining WPC cladding is relatively straightforward. Regular cleaning is essential to keep the surface free from dirt and grime. A simple wash with soap and water, along with a soft brush, is usually sufficient. Avoid using harsh chemicals or abrasive scrubbing tools, as these can damage the surface.

It is also important to inspect the cladding periodically for any signs of wear or damage. Addressing issues such as loose boards or signs of mold promptly will help ensure the longevity of the cladding. Additionally, consider applying a protective sealant or stain periodically to enhance the color and protect against fading due to UV exposure.

The successful installation of WPC cladding hinges on careful preparation, the right tools, and adherence to best practices. By understanding the unique characteristics of WPC materials and following systematic installation techniques, you can achieve a beautiful and durable finish that enhances the aesthetic appeal of any structure. With minimal maintenance requirements and a wide range of customizable options, WPC cladding presents a practical and stylish choice for modern building projects. As sustainability continues to be a focal point in construction, WPC cladding stands out as an innovative solution that combines functionality with environmental responsibility. Embracing these best practices will not only ensure a successful installation but also contribute to the long-term performance and satisfaction of your WPC cladding investment.