Evaluating Price of WPC Decking Floor for Your Renovation

Evaluating Price of WPC Decking Floor for Your Renovation When planning a home renovation, particularly when it comes to outdoor spaces, the choice of flooring can significantly impact both aesthetics and budget. One popular option that has gained traction in recent years is Wood-Plastic Composite (WPC) decking. This innovative material combines the best qualities of…

Evaluating Price of WPC Decking Floor for Your Renovation

When planning a home renovation, particularly when it comes to outdoor spaces, the choice of flooring can significantly impact both aesthetics and budget. One popular option that has gained traction in recent years is Wood-Plastic Composite (WPC) decking. This innovative material combines the best qualities of wood and plastic, offering durability, low maintenance, and resistance to elements. However, when considering WPC decking for your renovation project, understanding the pricing dynamics is crucial. A significant factor that influences these prices is the cost advantage of production areas, particularly in China.

China is known as a manufacturing powerhouse, and its production areas have established a reputation for offering cost-effective solutions across various industries, including WPC decking. One of the primary reasons for this cost advantage is the scale of production. Chinese manufacturers benefit from economies of scale, which allow them to produce large quantities of decking at a lower cost per unit. This means that they can pass on these savings to consumers, making WPC decking from China competitively priced compared to similar products from other regions.

Labor costs also play a significant role in the pricing of WPC decking. In many parts of China, labor costs are considerably lower than in Western countries. This enables manufacturers to maintain lower production costs while still ensuring high-quality standards. Skilled labor is available at a fraction of the cost, which helps to keep the overall expenses down. As a result, homeowners looking to renovate can take advantage of these savings when purchasing WPC decking manufactured in China.

Moreover, raw material sourcing is another critical factor contributing to the cost advantage of Chinese production areas. China has a well-established supply chain for the materials required to produce WPC decking, such as wood fibers and plastic resins. The abundance of these resources, coupled with competitive pricing from local suppliers, ensures that manufacturers can maintain low production costs. This vertical integration of supply chains allows for better control over quality and pricing, further enhancing the affordability of WPC decking.

In addition to the raw materials, China’s logistics infrastructure is highly developed. The country has invested heavily in transportation networks, including roads, railways, and ports, which facilitate the efficient movement of goods. This efficient logistics system reduces shipping times and costs, making it easier for manufacturers to distribute their products both domestically and internationally. For homeowners, this means that WPC decking can be delivered promptly and at a lower cost, contributing to overall savings in the renovation budget.

Environmental regulations in China have also evolved over the years, leading to improved manufacturing practices. Many Chinese manufacturers are now adhering to international standards for sustainability and eco-friendliness. This shift not only aligns with global trends toward greener production but also allows manufacturers to appeal to environmentally conscious consumers. As a result, homeowners can find WPC decking that meets eco-friendly criteria at competitive prices, making it an attractive option for those looking to renovate responsibly.

When comparing prices for WPC decking, it is essential to consider the quality of the product. While it may be tempting to choose the cheapest option available, it is crucial to evaluate the durability and longevity of the decking. Chinese manufacturers have made significant strides in producing high-quality WPC decking that can withstand various weather conditions and resist fading, splintering, and warping. Investing in quality decking may lead to long-term savings, as homeowners will spend less on repairs and replacements over time.

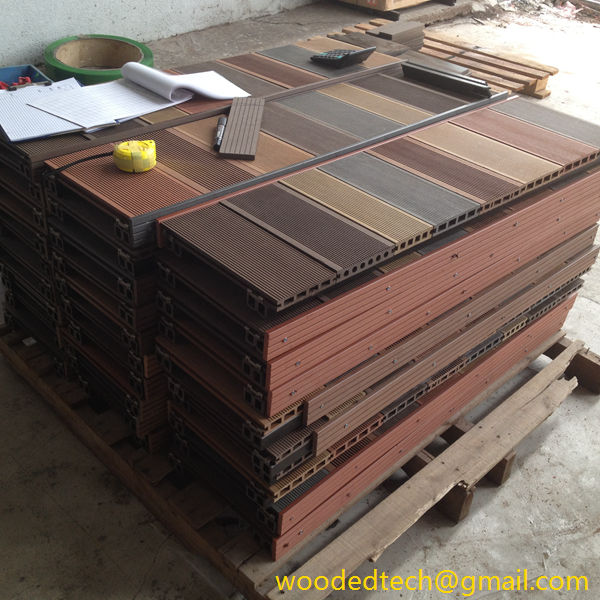

Another aspect to consider is the variety of styles and finishes available in WPC decking produced in China. With numerous manufacturers competing in the market, consumers have access to a wide range of options regarding colors, textures, and designs. This variety allows homeowners to find the perfect match for their renovation project without breaking the bank. The competitive landscape encourages innovation and design diversity, ensuring that there is something for every aesthetic preference.

While there are clear advantages to sourcing WPC decking from China’s production areas, it is essential to conduct thorough research before making a purchase. Homeowners should consider factors such as the reputation of the manufacturer, customer reviews, and certifications that ensure product quality. Engaging with suppliers who maintain transparency in their sourcing and manufacturing processes can also provide peace of mind.

In conclusion, evaluating the price of WPC decking for your renovation involves understanding the various factors that contribute to its cost. The cost advantage of China’s production areas plays a significant role in making WPC decking an affordable and appealing option for homeowners. With lower labor costs, efficient logistics, abundant raw materials, and improved manufacturing practices, Chinese manufacturers can offer competitive prices without compromising quality. By taking the time to research and choose the right product, homeowners can enjoy the benefits of WPC decking while staying within budget, making their renovation project a success.