Is Plastic Wood Strong? Evaluating Its Performance

Is Plastic Wood Strong? Evaluating Its Performance In recent years, the construction and design industries have seen a significant shift towards sustainable materials. Among these innovations, plastic wood—a composite material made from wood fibers and recycled plastic—has emerged as a popular alternative to traditional wood. This material claims to offer the aesthetic appeal of natural…

Is Plastic Wood Strong? Evaluating Its Performance

In recent years, the construction and design industries have seen a significant shift towards sustainable materials. Among these innovations, plastic wood—a composite material made from wood fibers and recycled plastic—has emerged as a popular alternative to traditional wood. This material claims to offer the aesthetic appeal of natural wood while providing enhanced durability and resistance to environmental factors. But is plastic wood really strong? In this article, we will explore the various aspects of plastic wood, assessing its performance, durability, and suitability for different applications.

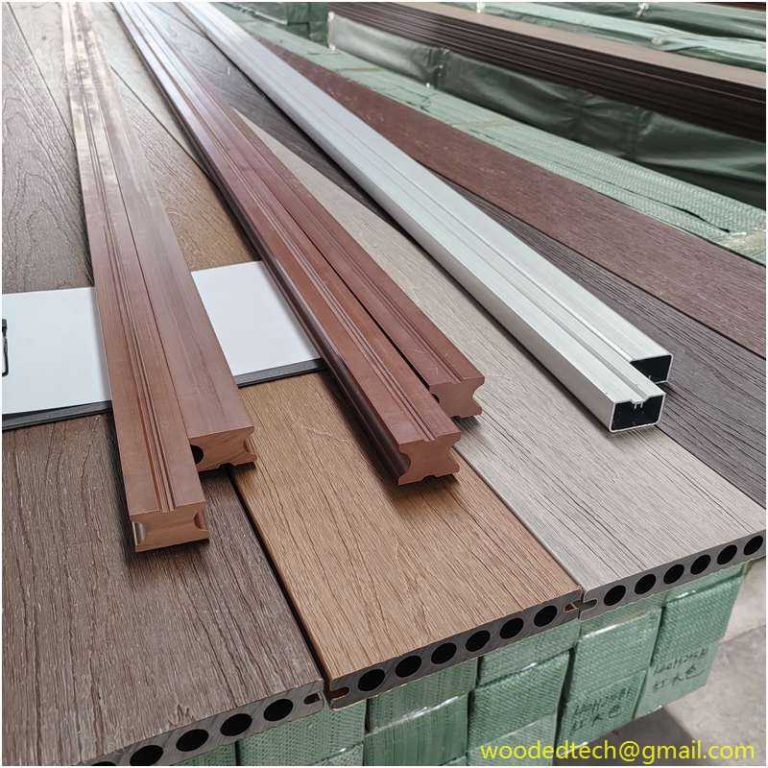

To understand the strength of plastic wood, it is essential to first examine its composition. Plastic wood typically consists of a blend of recycled plastics, such as polyethylene and polypropylene, combined with wood fibers. This combination results in a material that retains the look and texture of wood, while benefiting from the inherent strength of plastic. The wood fibers contribute to the material’s rigidity and structural integrity, allowing it to withstand various loads and stresses.

One of the key advantages of plastic wood is its resistance to environmental factors. Traditional wood is susceptible to rot, decay, and insect infestation, particularly in outdoor applications. Plastic wood, however, is not prone to these issues. It is impervious to moisture, which means that it won’t swell, crack, or warp when exposed to rain or humidity. This makes plastic wood an ideal choice for outdoor decking, fences, and furniture, where exposure to the elements is a concern.

Moreover, plastic wood is also resistant to UV rays, which can cause fading and deterioration in traditional wood over time. This UV resistance contributes to the longevity of the material, allowing it to maintain its color and appearance for years, even when placed in direct sunlight. As a result, homeowners and builders can enjoy the aesthetic benefits of wood without worrying about the maintenance and upkeep often required with natural materials.

When it comes to strength, plastic wood holds its own against traditional wood. While it may not possess the same tensile strength as some hardwoods, it is engineered to provide adequate strength for many applications. For instance, plastic wood decking is designed to support significant weight while resisting bending and deformation. This makes it suitable for high-traffic areas, such as patios and walkways, where strength and durability are essential.

In terms of load-bearing capacity, plastic wood performs admirably. Studies have shown that composite materials like plastic wood can withstand considerable pressure without compromising structural integrity. This quality makes it a viable option for various construction projects, including outdoor structures and landscaping features. The engineered nature of plastic wood allows for consistent performance, ensuring that it meets safety standards and building codes.

Another aspect to consider when evaluating the strength of plastic wood is its impact resistance. Traditional wood can splinter and crack upon impact, which can pose safety risks, especially in outdoor settings. In contrast, plastic wood is designed to absorb impact without breaking or splintering, making it a safer choice for families with children or pets. This characteristic enhances its appeal for playgrounds, park benches, and other public spaces.

While plastic wood offers numerous advantages, it is essential to acknowledge its limitations. Some critics argue that plastic wood may not provide the same aesthetic warmth and character as natural wood. For those who prioritize the authentic look and feel of wood, this may be a significant drawback. However, advancements in manufacturing techniques have led to the development of more realistic finishes and textures, allowing plastic wood to closely mimic the appearance of traditional wood.

Additionally, while plastic wood is durable, it can be more prone to scratches and scuff marks compared to harder woods. This is particularly true in high-traffic areas where heavy furniture may be dragged or moved frequently. Nevertheless, these minor cosmetic issues do not typically affect the overall performance or structural integrity of the material.

The environmental impact of plastic wood is another crucial consideration. As a composite material made from recycled plastics, it contributes to waste reduction and promotes sustainability. By utilizing materials that would otherwise end up in landfills, plastic wood offers an eco-friendly alternative to traditional lumber. Furthermore, the production process for plastic wood generally consumes less energy compared to that of harvesting and processing timber.

In conclusion, plastic wood proves to be a strong and durable alternative to traditional wood, particularly for outdoor applications. Its resistance to moisture, UV rays, and impact makes it an appealing choice for builders and homeowners alike. While it may not replicate the exact aesthetic qualities of natural wood, advancements in manufacturing have made it a more visually appealing option. Additionally, its contribution to sustainability makes plastic wood a responsible choice in today’s environmentally conscious world.

When considering materials for construction or design projects, it is essential to evaluate the specific requirements of each application. Plastic wood may not be suitable for every scenario, but it undoubtedly provides a strong and versatile option for many outdoor uses. As the demand for sustainable materials continues to grow, plastic wood is likely to play an increasingly prominent role in the future of construction and design, offering a blend of strength, durability, and environmental responsibility.