Master the Art of WPC Panel Fixing for a Professional Finish

Master the Art of WPC Panel Fixing for a Professional Finish Wood Plastic Composite (WPC) panels have emerged as a popular choice for both indoor and outdoor applications due to their durability, low maintenance, and aesthetic appeal. Unlike traditional wood, WPC panels do not warp, crack, or splinter, making them an ideal option for homeowners…

Master the Art of WPC Panel Fixing for a Professional Finish

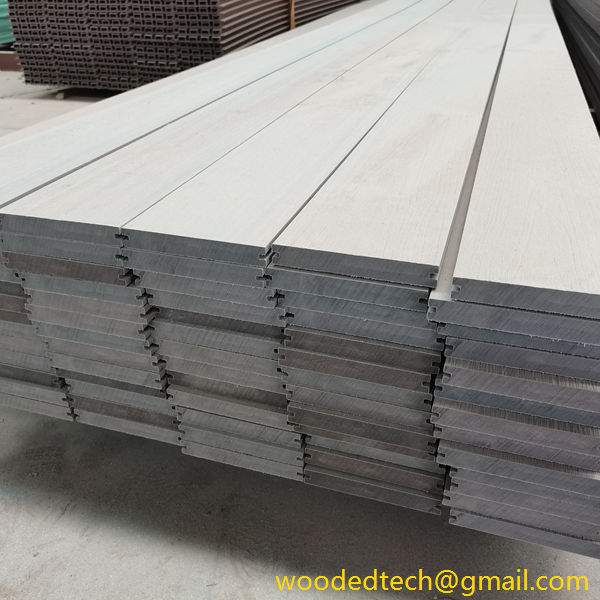

Wood Plastic Composite (WPC) panels have emerged as a popular choice for both indoor and outdoor applications due to their durability, low maintenance, and aesthetic appeal. Unlike traditional wood, WPC panels do not warp, crack, or splinter, making them an ideal option for homeowners and contractors looking for a long-lasting solution. However, achieving a professional finish with WPC panel installation requires careful planning and execution. In this guide, we will explore the best practices for fixing WPC panels to ensure a seamless and visually appealing result.

Before beginning any installation project, it is crucial to gather the necessary tools and materials. Essential tools for WPC panel fixing include a measuring tape, level, saw (preferably a circular saw), drill, screws, and a spacer. Additionally, having safety gear such as gloves and goggles is recommended to protect against potential injuries during the installation process.

Once you have gathered your tools, the first step is to prepare the area where the WPC panels will be installed. This involves ensuring the surface is clean, dry, and free of debris. For outdoor installations, it is advisable to choose a level surface to prevent any issues with drainage or stability. If you are installing WPC panels on a wall or fence, ensure that the structure is sturdy enough to support the weight of the panels.

Next, it is important to acclimate the WPC panels to the environment in which they will be installed. This means allowing the panels to sit in the installation area for a period of time, typically 48 hours, so they can adjust to the temperature and humidity levels. This step helps prevent any potential expansion or contraction after installation, which could lead to gaps or misalignment.

With the preparation complete, you can begin the installation process. Start by measuring and marking the desired height for the first row of panels. Use a level to ensure that your markings are straight and even. It is essential to take accurate measurements, as this will affect the overall appearance of the finished project.

When fixing the first panel, position it against the wall or surface and use screws to secure it in place. It is advisable to use stainless steel or coated screws to prevent rusting and ensure longevity. Pre-drilling holes is recommended to avoid splitting the panels, as WPC can be dense and difficult to drill into. Leave a small gap between the panel and any adjacent surfaces to allow for expansion.

As you continue installing additional panels, utilize spacers to maintain consistent gaps between each panel. This is crucial for aesthetic consistency and allows for natural expansion and contraction of the material. It is generally recommended to leave a gap of about 1/8 inch between panels, but refer to the manufacturer’s instructions for specific recommendations based on the product you are using.

When cutting WPC panels to fit around corners or edges, ensure that you use a fine-toothed saw to achieve a clean cut. Measure twice and cut once to minimize waste and ensure accuracy. If necessary, use a router to create smooth edges on the cut panels for a more polished look.

Once all panels are installed, it is important to check for any unevenness or misalignment. Use a level to ensure that everything is straight and make any adjustments as needed. If you notice any gaps or inconsistencies, you can use trim or molding to cover these areas and create a more finished appearance.

After the installation is complete, maintaining the WPC panels is relatively simple. One of the major advantages of WPC is its low maintenance requirements. Unlike traditional wood, WPC does not require regular sealing, staining, or painting. Instead, periodic cleaning with soap and water is usually sufficient to keep the panels looking their best. For tougher stains or dirt, a soft brush or pressure washer can be used, but it is essential to follow the manufacturer’s guidelines to avoid damaging the surface.

In addition to cleaning, it is also advisable to inspect the panels periodically for any signs of wear or damage. While WPC is designed to withstand various weather conditions and wear, being proactive about maintenance can extend the life of your installation. If you notice any loose screws or panels, address these issues promptly to prevent further damage.

In conclusion, mastering the art of WPC panel fixing can significantly enhance the appearance and durability of your projects. By following best practices in preparation, installation, and maintenance, you can achieve a professional finish that not only looks great but also requires minimal upkeep in the long run. Whether you are a seasoned contractor or a DIY enthusiast, investing the time and effort into properly fixing WPC panels will pay off with results that stand the test of time. With its many advantages, WPC is an excellent choice for anyone looking to elevate their space with a stylish and low-maintenance solution.