8 Meter Composite Decking Boards

8 Meter Composite Decking Boards The evolution of materials in construction and landscaping has been significantly influenced by the growing demand for sustainable, durable, and aesthetically pleasing products. Among these innovations, 8-meter composite decking boards have emerged as a leading choice for both residential and commercial applications. This article explores the technology behind composite decking,…

8 Meter Composite Decking Boards

The evolution of materials in construction and landscaping has been significantly influenced by the growing demand for sustainable, durable, and aesthetically pleasing products. Among these innovations, 8-meter composite decking boards have emerged as a leading choice for both residential and commercial applications. This article explores the technology behind composite decking, its production processes, and the advantages that 8-meter boards bring to the market.

Composite decking is primarily made from a blend of wood fibers and plastic, creating a material that combines the natural beauty of wood with the resilience of synthetic materials. The production of composite decking involves several key processes, including material selection, blending, extrusion, and finishing. Each stage is crucial in determining the performance characteristics of the final product.

The raw materials used in composite decking typically include recycled wood fibers sourced from sawmills, furniture manufacturing, and other industries. This not only reduces waste but also provides an environmentally friendly alternative to traditional wood decking. The plastic component is usually made from recycled polyethylene or polypropylene, which adds to the sustainability profile of composite decking. The combination of these two materials results in a product that is resistant to rot, decay, and insect damage—common issues faced by traditional wood decking.

Once the raw materials are gathered, the blending process begins. This involves mixing the wood fibers and plastic in specific ratios to achieve the desired properties. Different manufacturers may use varying formulations, which can affect the texture, color, and overall performance of the decking boards. The blending process is often enhanced by adding various additives that improve UV resistance, color retention, and overall durability. These additives play a critical role in ensuring that the composite decking can withstand the elements and maintain its appearance over time.

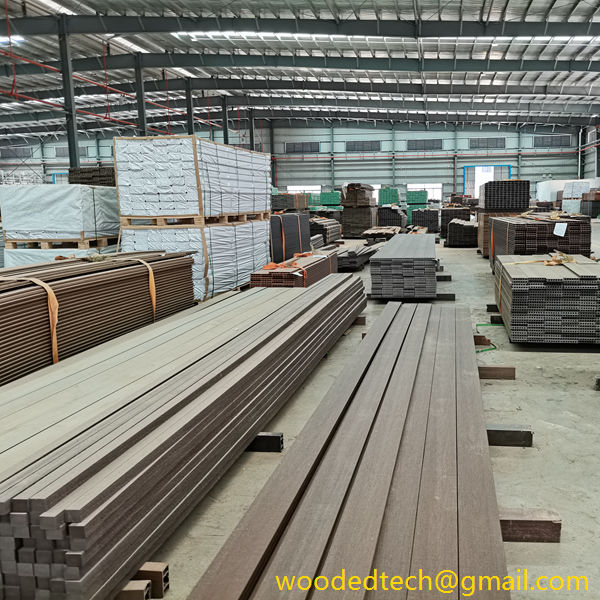

After blending, the mixture undergoes extrusion, a process where the blended material is heated and forced through a die to create long continuous boards. This method allows for the production of boards in various lengths, widths, and thicknesses. The production of 8-meter composite decking boards is particularly significant as it reduces the number of joints required in a deck installation, leading to a cleaner and more seamless appearance. Fewer joints also minimize potential weak points where water can accumulate, thereby reducing the likelihood of mold and mildew growth.

Once extruded, the boards undergo cooling and finishing processes. Cooling is essential to solidify the shape of the boards and ensure they retain their structural integrity. The finishing process may include sanding, texturing, or coating to enhance the aesthetic appeal of the boards and improve their slip resistance. Many manufacturers offer a range of colors and finishes, allowing consumers to choose options that best fit their design preferences.

One of the most significant advantages of 8-meter composite decking boards is their length. Traditional wood decking often comes in shorter lengths, requiring more cuts and joints during installation. The extended length of 8-meter boards not only simplifies the installation process but also contributes to a more visually appealing deck. A seamless look can enhance the overall aesthetic of outdoor spaces, making them more inviting for social gatherings and relaxation.

Moreover, the durability of composite decking is a standout feature. The combination of wood and plastic results in a material that can withstand harsh weather conditions, including intense sun, rain, and snow. Unlike traditional wood, composite decking does not warp, splinter, or fade easily, ensuring that it maintains its appearance and functionality for years. This longevity translates to lower maintenance costs for homeowners and property managers, as composite decking typically requires only periodic cleaning with soap and water.

Additionally, the environmental benefits of composite decking cannot be overlooked. By utilizing recycled materials, the production process contributes to waste reduction and conservation of natural resources. Furthermore, composite decking does not require chemical treatments like traditional wood, making it a safer choice for families and pets.

In conclusion, 8-meter composite decking boards represent a significant advancement in material production technology. The intricate processes involved in their creation—from material selection to extrusion—result in a product that combines aesthetic appeal with outstanding durability and sustainability. As consumers continue to prioritize environmentally responsible choices and low-maintenance solutions in outdoor living spaces, composite decking stands out as an optimal choice. The longer 8-meter boards not only enhance the visual quality of decks but also facilitate easier installation and maintenance. With the ongoing innovations in material technology, composite decking is poised to remain at the forefront of outdoor construction and design, meeting the evolving needs of modern consumers.