is composite decking waterproof

is composite decking waterproof The production process of outdoor composite decking is revealed: excellent waterproof performance, leading the trend of green environmental protection As a new type of environmentally friendly decorative material, outdoor composite decking has attracted widespread attention for its advantages such as waterproof, moisture-proof and anti-aging. Its unique production process ensures that the…

is composite decking waterproof

Het productieproces van outdoor samengestelde vloeren is revealed: excellent waterproof performance, leading the trend of green environmental protection

Als een nieuw type milieuvriendelijk decoratief materiaal, buiten samengestelde vloeren has attracted widespread attention for its advantages such as waterproof, moisture-proof and anti-aging. Its unique production process ensures that the plastic particles can completely wrap the wood powder, thus giving the product excellent waterproof performance. This article will analyze in detail the production process of outdoor samengestelde vloeren and why it can become a leader in the trend of green environmental protection.

2. Production process of outdoor samengestelde vloeren

1. Selection of raw materials

De grondstoffen van outdoor samengestelde vloeren mainly include plastic particles and wood powder. Plastic particles are made of high-quality PE, PP and other plastic raw materials, and wood powder is made of high-quality wood that has been specially treated. The combination of these two raw materials makes samengestelde vloeren waterproof, moisture-proof and anti-aging.

2. Mixing and stirring

Mix the plastic particles and wood powder in a certain proportion, and then send them into a high-speed mixer for full stirring. This process ensures that the plastic particles can evenly wrap the wood powder, creating conditions for subsequent extrusion molding.

3. Extrusion molding

The mixed materials are sent to the extruder, and the materials are extruded into the floor through high temperature and high pressure. This process requires the control of parameters such as extrusion speed, temperature and pressure to ensure the density and waterproof performance of the floor.

4. Cooling and shaping

The extruded floor is sent to the cooling device, and the floor is quickly cooled and shaped by the cooling water. This process can reduce the deformation and shrinkage of the floor during the cooling process and ensure the dimensional stability of the floor.

5. Surface treatment

In order to improve the wear resistance, weather resistance and aesthetics of the floor, the surface of the floor needs to be specially treated. Common treatment methods include painting, laminating, etc.

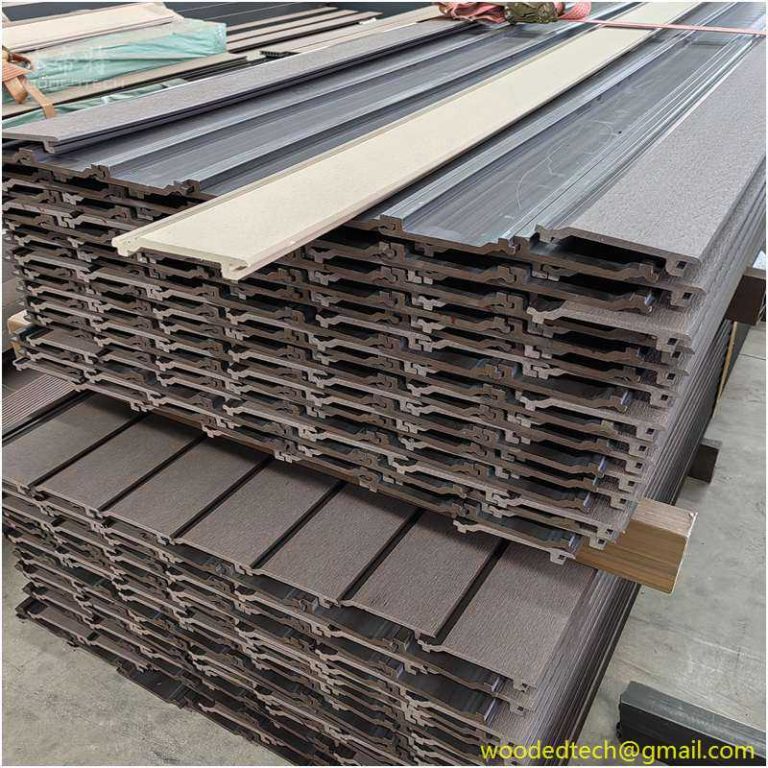

6. Cutting and packaging

The treated floor is cut and then packaged for easy transportation and installation.

III. Waterproof performance of outdoor samengestelde vloeren

The reason why outdoor samengestelde vloeren has excellent waterproof performance is mainly due to the following two aspects:

1. Plastic particles wrapped wood powder

During the production process, plastic particles can completely wrap wood powder, so that wood powder is isolated from moisture. In this way, even in a humid environment, the wood powder will not absorb moisture, thus ensuring the waterproof performance of the floor.

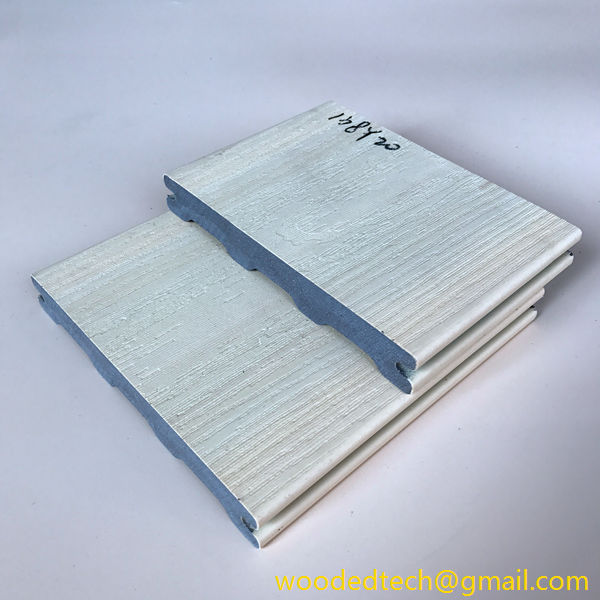

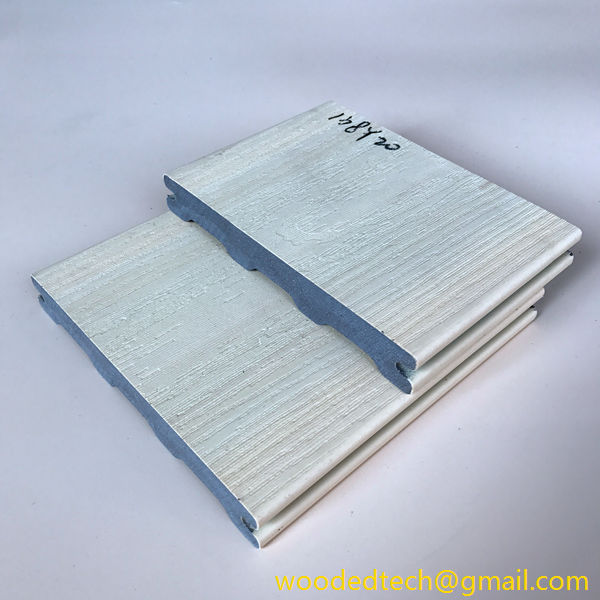

2. Seamless splicing design

Buiten samengestelde vloeren adopts a seamless splicing design, which forms a tight connection between the floors. In this way, moisture cannot penetrate into the interior of the floor, further improving the waterproof performance of the floor.

IV. Advantages of outdoor samengestelde vloeren

1. Excellent waterproof performance: Outdoor samengestelde vloeren has excellent waterproof performance and will not deform or rot even in a humid environment.

2. Environmentally friendly and pollution-free: The production process of samengestelde vloeren does not produce harmful substances and can be recycled, which is in line with the concept of green environmental protection.

3. Wear-resistant and anti-aging: The surface of outdoor samengestelde vloeren has been specially treated and has excellent wear resistance and anti-aging properties.

4. Easy installation: Composiet terrasvloeren adopts a splicing design, which is easy and quick to install, saving time and effort.

5. Beautiful and generous: Outdoor samengestelde vloeren has rich colors and natural textures, which can meet the decoration needs of different places.

V. Conclusion

Buiten samengestelde vloeren has become a shining pearl among plastic products with its unique production process to ensure waterproof performance. It not only meets people’s demand for green environmental protection, but also provides excellent decorative effects. With the continuous development of science and technology, the application field of outdoor samengestelde vloeren will become more and more extensive, becoming an important force leading the trend of green environmental protection.