Che cos'è il composito polimerico di legno: Scopri i vantaggi dei compositi polimerici di legno

Che cos'è il composito polimerico di legno: Scopri i vantaggi dei compositi legno-polimero I compositi legno-polimero (WPC) sono materiali innovativi che combinano le proprietà naturali del legno con la versatilità dei polimeri, dando vita a un composito che offre numerosi vantaggi per varie applicazioni. Con la continua crescita della domanda di materiali sostenibili ed ecologici, i WPC hanno...

Che cos'è il composito polimerico di legno: Scopri i vantaggi dei compositi polimerici di legno

Wood Polymer Composites (WPCs) are innovative materials that combine the natural properties of wood with the versatility of polymers, resulting in a composite that offers numerous benefits for various applications. As the demand for sustainable and eco-friendly materials continues to rise, WPCs have gained significant attention in industries such as construction, furniture, automotive, and consumer products. This article aims to explore what Wood Polymer Composites are, their composition, manufacturing processes, benefits, and their potential applications.

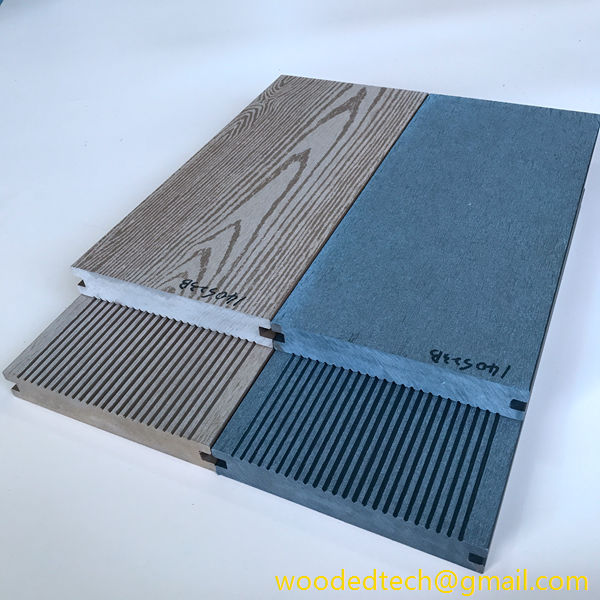

Wood Polymer Composites are typically composed of wood fibers or wood flour combined with thermoplastic polymers. The wood component may come from various sources, including recycled wood, sawdust, or wood shavings. The polymer component can be made from both virgin and recycled plastics. Common polymers used in the production of WPCs include polyethylene, polypropylene, and polystyrene. The combination of these materials results in a composite that retains the aesthetic appeal of wood while enhancing its durability, moisture resistance, and overall performance.

The manufacturing process of Wood Polymer Composites generally involves several key steps. First, the wood fibers must be dried to a specific moisture content to ensure optimal bonding with the polymer. Next, the wood and polymer components are mixed together, often using additives that can enhance the properties of the final product. These additives can include colorants, UV stabilizers, and flame retardants, among others. The mixture is then processed using techniques such as extrusion or injection molding to create the desired shape and size of the composite material. The result is a versatile and durable product that can be used in a variety of applications.

One of the primary benefits of Wood Polymer Composites is their enhanced durability compared to traditional wood products. WPCs are resistant to moisture, rot, and insect damage, making them an ideal choice for outdoor applications such as decking, fencing, and landscaping. Unlike untreated wood, WPCs do not warp or crack under varying weather conditions, which extends their lifespan and reduces maintenance costs. This durability makes WPCs a preferred alternative in environments where exposure to moisture and insects is a concern.

Another significant advantage of Wood Polymer Composites is their sustainability. The use of recycled wood and plastics in their production contributes to waste reduction and promotes the circular economy. By repurposing materials that would otherwise end up in landfills, WPCs help conserve natural resources and reduce the environmental impact associated with the extraction and processing of virgin materials. Additionally, WPCs can be designed to be fully recyclable at the end of their life cycle, further contributing to environmental sustainability.

Aesthetically, Wood Polymer Composites offer the warmth and beauty of natural wood without the drawbacks associated with traditional wood products. WPCs can be manufactured in various colors and finishes, allowing for greater design flexibility. They can mimic the appearance of natural wood grain while providing a consistent look and feel. This versatility makes them suitable for various applications, from residential decking and outdoor furniture to interior design elements.

Moreover, Wood Polymer Composites are lightweight compared to traditional wood materials, making them easier to handle and install. Their reduced weight can lead to lower transportation costs and increased efficiency in construction projects. This characteristic is particularly advantageous in applications such as modular building systems and prefabricated components, where weight and ease of assembly are critical factors.

The use of Wood Polymer Composites also aligns with contemporary trends towards health and safety. WPCs do not require harmful chemical treatments that are often necessary for traditional wood products to resist decay and insect damage. This absence of toxic chemicals makes WPCs a safer choice for indoor applications, such as furniture and wall paneling, where air quality is a concern. Additionally, WPCs are often free from splinters and other hazards associated with traditional wood, making them suitable for family-friendly environments.

In terms of market potential, the demand for Wood Polymer Composites is expected to continue growing. The increasing focus on sustainability, combined with the versatility and performance advantages of WPCs, positions them as a strong alternative to traditional materials. Industries such as construction, automotive, and consumer goods are increasingly adopting these composites due to their superior properties and environmental benefits.

In conclusion, Wood Polymer Composites represent a significant advancement in material production technology, combining the best qualities of wood and polymers. Their enhanced durability, sustainability, aesthetic appeal, and safety make them an attractive choice for a wide range of applications. As industries continue to seek innovative solutions that align with environmental stewardship and performance standards, WPCs are poised to play an essential role in the future of material production. With ongoing research and development, the potential for Wood Polymer Composites will likely expand, further solidifying their place in the marketplace.