How to Fix WPC Cladding: Solutions for Fixing WPC Cladding Issues

How to Fix WPC Cladding: Solutions for Fixing WPC Cladding Issues WPC, or wood-plastic composite, cladding has gained popularity in recent years due to its aesthetic appeal and durability. It combines the best properties of wood and plastic, making it resistant to moisture, insects, and decay. However, like any building material, WPC cladding can encounter…

How to Fix WPC Cladding: Solutions for Fixing WPC Cladding Issues

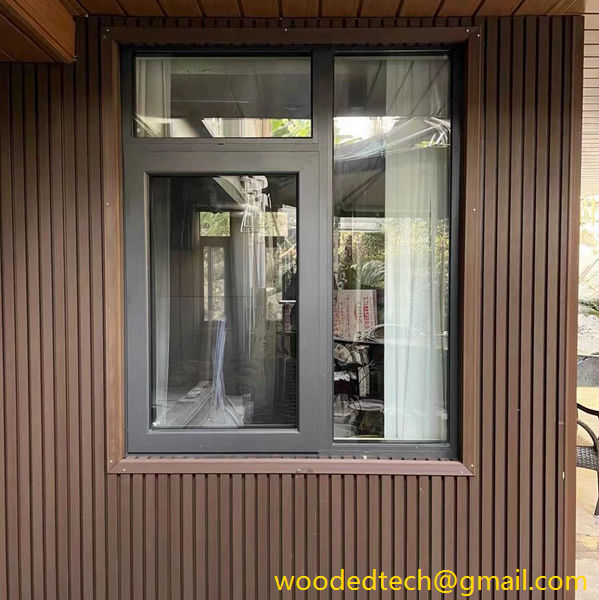

WPC, or wood-plastic composite, cladding has gained popularity in recent years due to its aesthetic appeal and durability. It combines the best properties of wood and plastic, making it resistant to moisture, insects, and decay. However, like any building material, WPC cladding can encounter issues over time. Understanding how to fix these problems is essential for maintaining its performance and ensuring longevity. This article outlines common WPC cladding issues and presents effective solutions.

One of the most frequent issues faced with WPC cladding is warping. This can occur due to temperature fluctuations and moisture absorption. Warping not only alters the appearance of the cladding but can also compromise the structural integrity of the installation. To fix warped WPC cladding, first inspect the affected areas to determine the extent of the damage. If the warping is minor, it may be possible to realign the planks. This can involve loosening the fasteners, adjusting the position of the planks, and then re-tightening them to ensure a snug fit.

If the warping is severe, replacing the affected boards may be necessary. Carefully remove the warped boards using a pry bar or similar tool. Ensure that you have replacement boards that match the original material to maintain a consistent look. When installing the new boards, make sure to leave adequate spacing for expansion and contraction, which can help prevent future warping.

Another common issue is fading or discoloration of the WPC cladding due to prolonged exposure to sunlight. While WPC materials are designed to resist UV damage better than traditional wood, they are not entirely immune. To address fading, consider applying a specialized WPC stain or sealant designed to restore color and provide UV protection. Before application, ensure that the surface is clean and dry. Pressure washing can help remove dirt and debris, allowing the stain or sealant to adhere better.

In cases where fading has significantly altered the appearance of the cladding, replacing sections may be necessary. Choose boards that are treated with UV inhibitors to minimize future fading. Additionally, consider installing an overhang or awning to provide shade and protect the cladding from direct sunlight.

Mold and mildew growth is another issue that can arise with WPC cladding, particularly in humid environments. Mold not only affects the appearance of the cladding but can also pose health risks. To address mold and mildew, start by cleaning the affected areas with a mixture of mild detergent and water. A soft-bristle brush can help scrub away any stubborn growth. For more persistent mold, a mixture of vinegar or bleach and water can be effective, but be cautious as these substances may affect the color of the WPC.

To prevent future mold growth, ensure that the cladding is installed with proper ventilation and drainage. Regular cleaning is also essential to remove organic materials that can contribute to mold growth. In particularly damp environments, consider using a mold-resistant sealant as an additional protective measure.

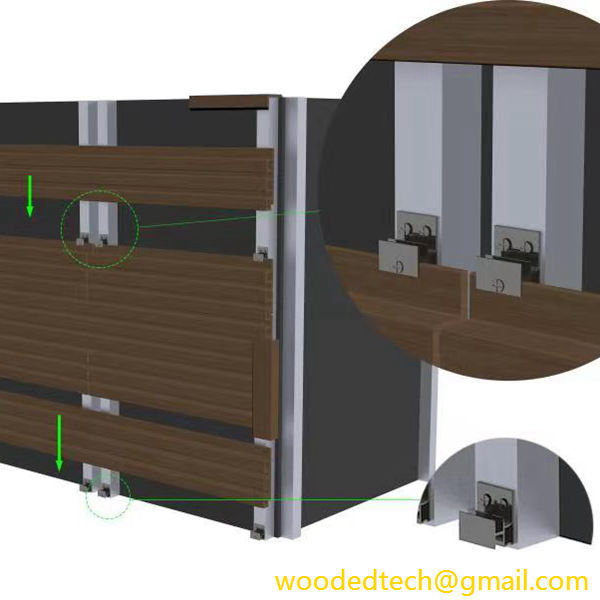

Loose or missing fasteners can lead to gaps between the boards, which not only affects the appearance of the cladding but can also lead to water infiltration and other damage. Regularly inspect the cladding for any loose or missing fasteners and replace them as necessary. When installing new fasteners, choose materials that are corrosion-resistant to enhance durability.

Another issue that may arise is the accumulation of dirt and grime on the surface of the WPC cladding. This can dull the appearance of the material and detract from its aesthetic appeal. To clean the cladding, use a gentle detergent mixed with water and a soft-bristle brush or sponge. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the WPC. After cleaning, rinse thoroughly with water to remove any soap residue.

Cracking can also occur in WPC cladding, often resulting from improper installation or extreme temperature changes. If you notice small cracks, they can often be filled with a high-quality exterior-grade caulk or sealant designed for WPC materials. For larger cracks or splits, it may be necessary to replace the affected boards entirely. As with warping, ensure that any replacement boards match the original material to maintain a cohesive look.

Lastly, proper installation techniques play a crucial role in the performance of WPC cladding. Ensure that the boards are installed according to the manufacturer’s guidelines. This includes allowing for proper spacing between boards to accommodate expansion and contraction, using appropriate fasteners, and ensuring adequate ventilation behind the cladding. Following these guidelines can help mitigate many common issues before they arise.

In conclusion, while WPC cladding is a durable and attractive option for exterior applications, it is not without its challenges. By understanding common issues such as warping, fading, mold growth, loose fasteners, dirt accumulation, and cracking, homeowners and builders can take proactive steps to address these problems. Regular maintenance, proper installation, and timely repairs are key to ensuring the longevity and performance of WPC cladding. With the right approach, it is possible to maintain the beauty and functionality of WPC cladding for many years to come.