كيفية التمييز بين جودة الأرضيات البلاستيكية الخشبية (WPC التزيين) من الجيد إلى الرديء

كيفية التمييز بين جودة الأرضيات البلاستيكية الخشبية (WPC التزيين) من الجيد إلى السيئ المواد الخشبية البلاستيكية المركبة هي نوع من المواد المصنوعة أساسًا من مسحوق الخشب (السليلوز الخشبي، السليلوز النباتي) وراتنج البوليمر بالحرارة مثل HDPE (البلاستيك) ومختلف مساعدات معالجة البلاستيك. بعد أن يتم خلطها وتحبيبها بالتساوي، يتم بعد ذلك تصنيعها بالتقنية العالية...

كيفية التمييز بين جودة الأرضيات البلاستيكية الخشبية (WPC التزيين) من الجيد إلى الرديء

Wood-plastic composite material is a kind of material mainly made of wood powder (wood cellulose, plant cellulose) and thermoplastic polymer resin such as HDPE (plastic) and various plastic processing aids. After being evenly mixed and granulated, it is then The high-tech green environmentally friendly material extruded by the mold equipment on the extruder has the properties and characteristics of wood and plastic. It is a new environmentally friendly high-tech material that can replace wood and plastic. Its English abbreviation of Wood Plastic Composites is WPC. .

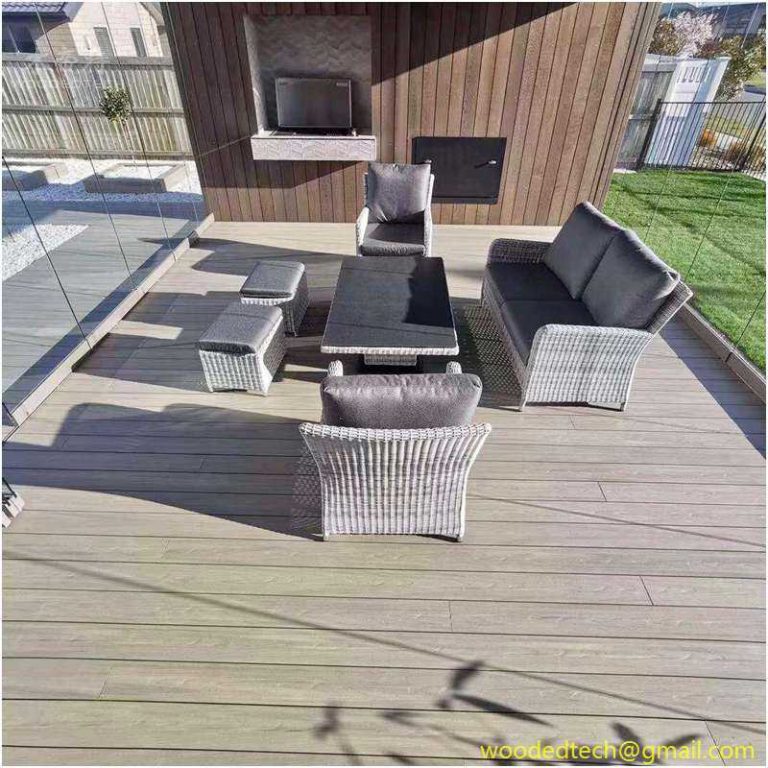

Wood-plastic flooring is a floor made of wood-plastic composite materials. It has similar processing characteristics to wood. It can be sawed, drilled, and nailed using ordinary woodworking tools. It is very convenient and can be used like ordinary wood. It has the woody feel of wood and the water-resistant and anti-corrosion properties of plastic, making it an excellent and durable outdoor waterproof and anti-corrosion building material.

Plastic wood flooring is a new type of outdoor home building material. Since it was introduced in China and successfully developed and put on the market in the early 2000s, it has gradually been widely recognized by users. It has created good economic benefits while also creating a good reputation. social benefits. So, back to the topic, how can we judge the quality of plastic wood flooring when we buy it daily?

First, check the quality of the floor from its appearance. If there are obvious scratches, cracks, dark lines and other problems on the appearance, it means that this series of products has major production defects and you cannot choose this product. If there are some white fiber-shaped objects on the surface, many people think that this is the reason for the poor quality of the floor. In fact, this is not the case. This is because fiber substances are added to the raw materials, which can make the board stronger. However, if the added fiber is not fine enough, large white spots will appear, which will affect the appearance.

Secondly, an important factor that affects product quality is the raw materials used. The quality positioning and quality stability of the raw materials directly restrict the service life of the floor. The testing of raw materials is an extremely important process for manufacturers, especially It is about two large raw materials, wood powder and plastic. However, the application testing of raw materials requires professional testing procedures, which cannot be seen from the appearance. For two plastic boards using different raw materials, their appearance may not be much different, and depending on the base material, which board may look better may be just the appearance, not necessarily the intrinsic quality. difference.

High-quality plastic wood flooring has certain advantages in terms of thickness, flatness, smoothness, etc. We generally judge the quality of the material by observing these aspects. If the product has various problems such as cracking and fading soon after leaving the factory, Seriously, it is a sign of poor quality. This can serve as an important criterion for users to judge its quality.

Finally, when choosing to purchase, you should check whether the supplier has a good reputation, whether the product has after-sales service, and whether the material has a warranty, instead of just trying to get the lowest price. In this way, the purchased wood-plastic flooring is more likely to be of good quality, and ultimately Validate your initial choices through the test of time.

and-application-pictures-2-768x768.jpg)